Chapter 2

2-5

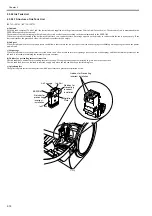

2. Print drive timing

Each printhead houses 12 trains of nozzles, which share the same data transfer clock (Hx-CLK) and data latch pulses (Hx-LT).

Even-numbered nozzle data (Hx-x-DATA-x-EV), odd-numbered nozzle data (Hx-x-DATA-x-OD) and the Heat Enable (Hx-x-HE-x) signal are generated for each

nozzle train and controlled individually.

Printing is carried out in two ways through reciprocating motion of the carriage.

An encoder sensor mounted on the carriage generates a 150-dpi-pitched linear scale detection signal (ENCODER_A) and a signal (ENCODER_B) shifted 120 de-

grees in phase. The direction of carriage motion is detected from the status of the ENCODER_B signal relative to the leading edge of the ENCODER_A signal.

The printhead is driven using a 2400-dpi timing signal (internal signal), which is generated by dividing the ENCODER_A signal detected at the 150 dpi timing into

16 equal sections.

Printing in the forward direction is triggered at the leading edge of the detection signal (ENCODER_A).

Printing in the backward direction is carried out the same way as printing in the forward direction but at the trailing edge of the detection signal (ENCODER_A),

when the order of heated nozzles is reversed depending on the sequence of transfer of even-numbered nozzle data and odd-numbered nozzle data.

F-2-5

150dpi

2400dpi

Internal signal

2400dpi

Low active

Linear scale

Data of block 0

Data of block 0

Data of block 0

Data of block 0

Data of block 2

Data of block 2

Data of block 2

Data of block 2

Data of block 4

Data of block 4

Data of block 4

Data of block 4

Data of block 22

Data of block 22

Data of block 22

Data of block 22

ENCODER_A

ENCODER_B

H0_CLK

H0_A_DATA_0_EV

H0_A_DATA_1_EV

H0_LT

H0_A_HE_1

H0_A_DATA_0_OD

H0_A_DATA_1_OD

Summary of Contents for iPF750 series

Page 1: ...Jul 25 2012 Service Manual iPF760 750 series ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Page 12: ......

Page 14: ...Contents 1 7 3 5 Self diagnostic Feature 1 71 1 7 3 6 Disposing of the Lithium Battery 1 72 ...

Page 87: ...Chapter 2 TECHNICAL REFERENCE ...

Page 88: ......

Page 99: ...Chapter 2 2 9 ...

Page 145: ...Chapter 3 INSTALLATION ...

Page 146: ......

Page 148: ......

Page 152: ......

Page 153: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Page 154: ......

Page 156: ......

Page 214: ...Chapter 4 4 58 2 Shaft Cleaner 1 F 4 119 1 ...

Page 215: ...Chapter 4 4 59 3 Upper Cover Hinge Catch 1 Roll Cover Slide Guide 2 F 4 120 2 1 ...

Page 218: ......

Page 219: ...Chapter 5 MAINTENANCE ...

Page 220: ......

Page 222: ......

Page 227: ...Chapter 5 5 5 ...

Page 228: ......

Page 229: ...Chapter 6 TROUBLESHOOTING ...

Page 230: ......

Page 232: ......

Page 250: ......

Page 251: ...Chapter 7 SERVICE MODE ...

Page 252: ......

Page 254: ......

Page 305: ......

Page 306: ......

Page 307: ...Chapter 8 ERROR CODE ...

Page 308: ......

Page 310: ......

Page 327: ...Jul 25 2012 ...

Page 328: ......