Page 23 of 41

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

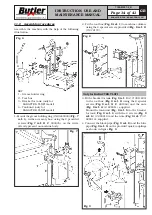

4. Press the pedal to turn the wheel clockwise until

the whole bead has been lifted from the rim. During

the rotation of the wheel, the bead lifting tool slides

away from the mounting tool moving onto the rim

edge. The plastic protector prevents the lever from

scratching the rim.

5. Lift the tyre and repeat the operation on the other

bead.

On heavy low-profile tyres, for an easier and safer

demounting, once the upper bead has been broken, it

is advisable to keep pressing until obtaining enough

space to lubricate the groove, the bead seating, and

the bead itself. (see

Fig. 31

). Failure to lubricate might

cause friction between the mounting tool and the tyre,

and would cause damage to the tyre and/or the bead.

Lubricate

Fig. 31

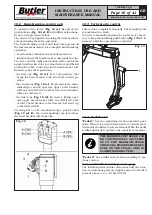

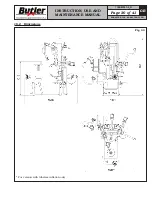

When the upper bead is being demounted, it might

happen that the lower bead re-sets in the rim. In this

case use bead breaker’s lower roll to bead-break again,

and if the tyre should be very wide, push it up to the

mounting tool (see

Fig. 32

).

Fig. 32

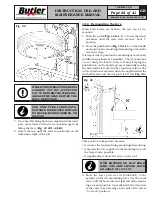

When demounting hard tyres, it may happen that

the bead comes onto the mounting tool with the lip

turned. This causes the bead to slide from the lever

when clockwise rotation begins. To avoid this problem

rotate the wheel slightly anti-clockwise until the bead

flattens. Now the clockwise demounting cycle can begin

(see

Fig. 33

).

NO

YES

Fig. 33

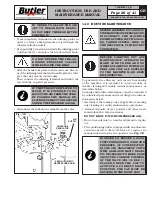

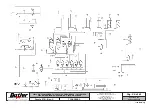

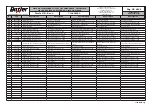

When demounting hard low-profile tyres, it might

happen that the bead pushes up the mounting tool. It

may be found useful to use the upper bead-breaking

roller to push the bead down to create enough space

to position the lever and at the same time pushing up

the tool holder arm down (

Fig. 34

).

Fig. 34

KARACTER.TLX - KARACTER.TLXFI

7108-M007-0_B