Page 25 of 41

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

13.9 Special use of the bead-breaker

In addition to its use during mounting and demounting,

the bead-breaker roll can also be used for matching

the tyre to the rim. To conduct this operation carry out

the following instructions.

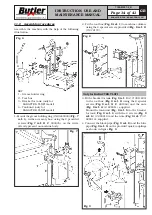

• Clamp the tyre between the bead breaker roll.

• Turn the mandrel clockwise until the reference point

on the tyre coincides with the reference point on the

rim (usually the valve) (see

Fig. 36

).

Fig. 36

13.10 Tyre inflation with machine without

tubeless inflation

Connect the inflation device to the tyre valve and inflate

the same tyre using the pedal provided (

Fig. 14 ref. 2

).

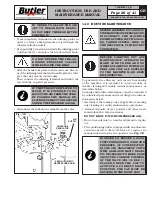

A SAFETY DEVICE IS PRESENT

FOR THE ADJUSTMENT OF THE

MAXIMUM PRESSURE OF THE

SUPPLIED AIR (4,2 ± 0,2 BAR /

60 PSI).

Well lubricated beads and rims make the beading in

and inflation much safer and easier.

In case the beads are not seated at 4.2 ± 0.2 bar,

release all the air from the wheel, remove it from the

tyre changer and put it in a safety cage to complete

the inflation procedure.

13.11 Tyre inflation with machine with tube-

less inflation

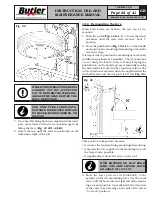

Some types of tyres can be difficultly inflated if the

beads are not in contact with the rim. The tubeless

inflation device supplies a jet of high-pressure air from

the nozzle, which encourages the correct positioning

of the bead against the rim, and therefore normal

inflation.

In order to carry out the inflation of the tyre follow

these indications:

• Remove the valve stem core.

Removing the valve stem core will allow the tyre to

inflate faster and the bead to seat easier.

• Connect the inflation terminal to the valve of the tyre.

TO IMPROVE THE EFFECTIVE-

NESS OF TUBELESS INFLATION

SYSTEM, ALWAYS LUBRICATE

TYRE BEADS.

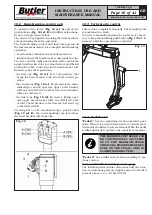

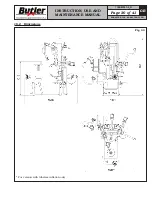

• Press the bead blaster hose on the wheel rim as

shown in

Fig. 37

. Ensure the hose head is pressed

in to activate the additional air jet.

THE NOZZLE SHOULD BE HORI-

ZONTAL FOR OPTIMAL PERFOR-

MANCE (FIG. 37).

Fig. 37

KARACTER.TLX - KARACTER.TLXFI

7108-M007-0_B