Page 22 of 41

GB

INSTRUCTION, USE AND

MAINTENANCE MANUAL

13.6 Demounting the tyre

When both beads are broken, the tyre can be de-

mounted.

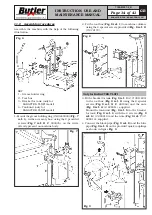

1. Push the pedal (

Fig. 14 ref. 1

) to rotate the wheel

clockwise until the valve stem reaches “hour 1”

position.

2. Press the push button (

Fig. 13 ref. 1

) on the handle

and position the mounting/demounting arm on the

rim outer edge.

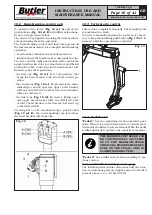

It is important to position the mounting arm correctly

(2 different positions are possible). The two positions

are set using the knob on the rod and, keeping the

push button on the handle pressed, manually moving

the arm until it is locked in the required position. The

correct position is achieved when the angle between the

tool holder arm and the rim plate is 90° (see

Fig. 30

).

Fig. 30

This position is important because:

• It reduces the tension during mounting/demounting.

• It spreads the force applied to the mounting tool over

the largest area possible.

• It significantly reduces the wear on the tool.

WITH ROUNDED OR FLAT EDGE

RIMS, THE ARM SHOULD HAVE

AN ANGLE OF 100°/110°.

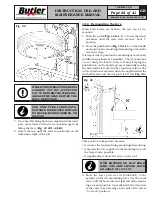

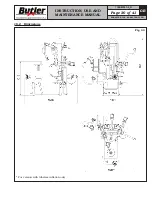

3. Move the lever protector (# B0326001) to the

pointed end of the bead lifting lever. Use the same

lever to lift the bead onto the right end of the mount-

ing tool and position it parallel with the rim plate

at the same time pressing on the side of the tyre at

“6 o’clock” position.

Fig. 29

WHILE THIS OPERATION IS BEING

CARRIED OUT PAY ATTENTION

NOT TO DEFORM THE TYRE SIDE.

GREASE THE BEAD BEFORE THE

ROLL RE-ENTERS.

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

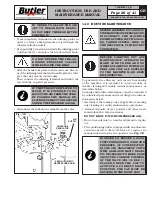

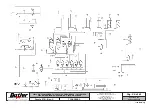

7. Once bead breaking has been completed in the lower

part, move lower roll in the rest position again, by

lifting the lever (

Fig. 12 rEf. A (LH)

).

8. Rotate the rim until the valve is positioned on the

immediate right of the roll.

KARACTER.TLX - KARACTER.TLXFI

7108-M007-0_B