CCD-Premium

Operating manual

page 22 /24

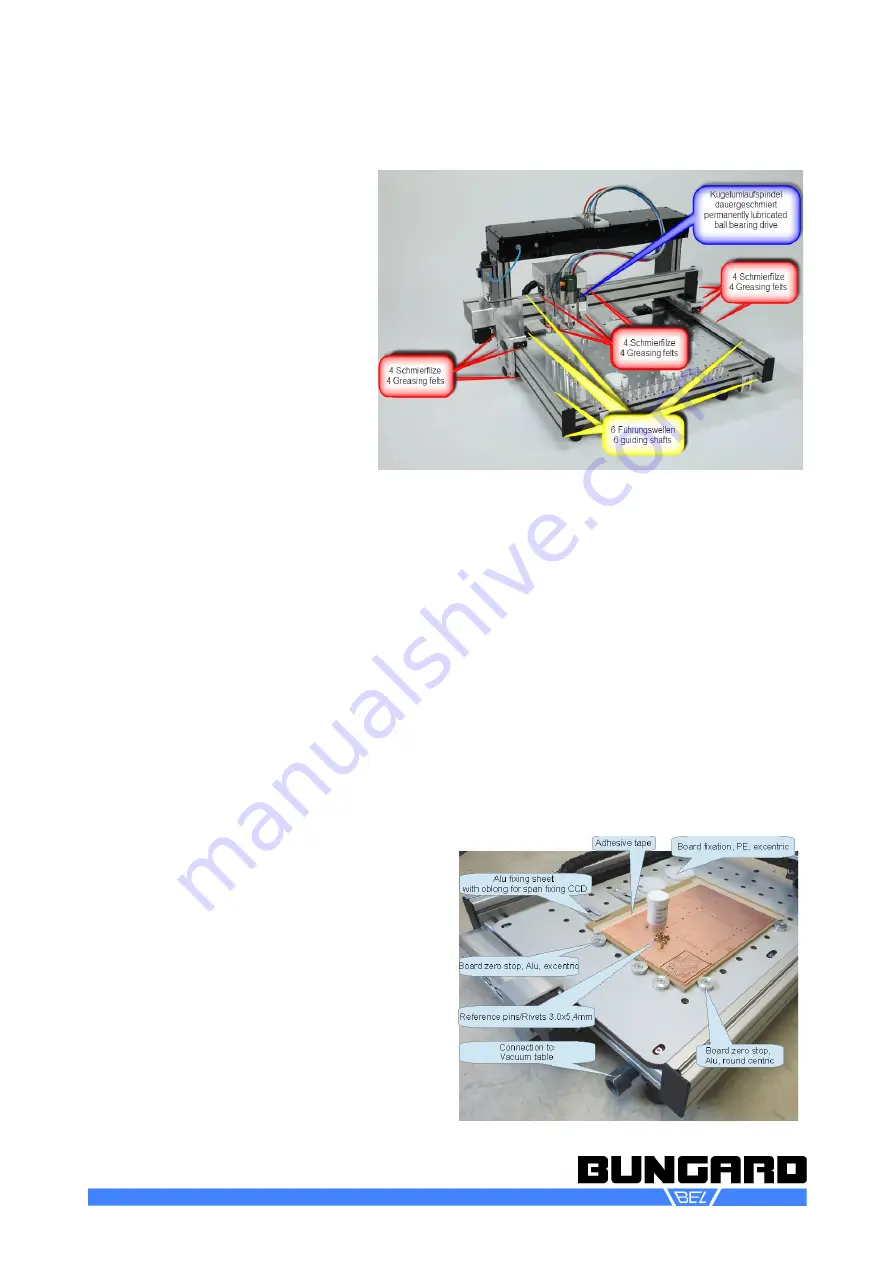

On the sides of the linear housings

there are small felt tips which

automatically clean the steel shafts

with each movement. Apply on these

felt tips (at best with some syringe with

a fine needle) a few drops of an acid-

free and low-viscosity engine oil.

The felts ensure that there is always a

thin film of oil on the steel shafts,

which ensures smooth movement and

the protects the shafts against

corrosion.

The guide shafts of the Z-axis should

regularly cleaned of dust and chips

with a lint-free cloth. They need no

further lubrication, since the linear

bushings and the ball screw have a

permanent lubrification.

Note

: The machine must not be used in corrosive or inflammable atmospheres. If it will not be used for

a longer period or prior to transporting it, all steel shafts should be well lubricated.

The drive belts must also be kept clean from dust and shavings but must not not be lubricated. The

belts are subject to wear. If they show damages like lateral fray-out or deformed teeth they should be

replaced.

Fixing the boards

Clamp fixing

The machine table has holes each 50 mm. They serve to fix the aluminium and plastic flanges coming

with the machine and allow to clamp on all four edges 1 base sheet and 1 - 3 boards of the same size

of 1.5 mm. The two flanges near to the machine's zero position determine the board zero position. Use

the two big white plastic discs with the 3 eccentric mounting holes to clamp the boards. The small ec -

centric flanges can be used to align the board(s) in parallel to a main axis. This fixing method is in most

cases sufficient for all drilling applications, as well as for fixing a base sheet for isolation milling and

contour cut-out routing. Disadvantage: backing board and PCB must have the same size.

Span fixing

You may insert screws into the holes in the ma-

chine table. Using stripes of metal or PCB mater-

ial, this offers you the possibility to fix the plates

from on top. This method will apply mainly for en-

graving aluminium. Disadvantage: the metal

stripes lie on top of the plate and may be touched

by the spindle.

Reference pins / Isolation milling

Use a drilling base that is significantly larger than

the board. Create a drill file with two or six refer-

ence holes. These reference holes form a mirror

axis, which is needed to reference the bottom

Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany

Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: [email protected]