186CNV / 284ANV: Service Manual

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

5

Variable Frequency Drive (VFD)

The VFD converts single phase 60 Hz line power into a variable

frequency, variable voltage, 3-phase output to drive the compressor at

the speed requested by the control system. This function is performed

by first converting the incoming line power to an intermediate high

voltage DC supply. The high voltage DC supply is then converted to a

3-phase output by a variable frequency inverter for driving the

compressor. The VFD also provides high voltage DC supply power to

the fan motor.

The VFD contains numerous protection modes for maximizing

reliability and preventing faults in wiring or the compressor and fan

components from causing failures within the VFD.

VFD Filter Board

The VFD filter board blocks electrical noise generated within the VFD

from back-feeding onto the line power feed to the equipment. It contains

non-replaceable fuses which will protect the VFD in the event of a

severe power surge condition.

Reactors

Reactors are part of the VFD incoming power conversion circuit. The

reactors enable boosting of incoming line power when necessary and

also provide power factor correction.

High Pressure Switch (HPS)

The HPS is a normally closed switch connected to VFD control circuitry.

The HPS opens when the compressor discharge pressure reaches 670

psig. When the switch opens, a control input to the VFD is disabled and

causes the compressor and fan to shut down. When compressor

discharge pressure decreases to 470 psig, the switch closes and allows

equipment operation to resume.

Compressor Brushless Permanent Magnet Motor

(BPM)

The compressor uses a highly efficient, brushless permanent magnet

motor. Motor speed is synchronized to, and controlled by the frequency

of the drive provided by the VFD.

VFD + Compressor BPM

Compressor runs at variable speeds controlled by the VFD.

The VFD controls acceleration and deceleration speeds of the

compressor. Speed changes are typically limited to 60 rpm per second.

The VFD will automatically limit compressor speed if compressor load

current reaches operating limits.

Fan Brushless Permanent Magnet Motor (BPM)

The fan uses a highly efficient, brushless permanent magnet motor.

Motor speed is synchronized to, and controlled by an on-board variable

frequency inverter (VFI) integrated with the motor and located within

the motor housing. The VFI uses the high voltage DC supply provided

by the VFD to drive the fan, and a low voltage control signal from the

VFD to determine fan speed. The fan provides a feedback signal to the

VFD indicating fan speed.

VFD + Fan BPM

The fan runs at a variable speed over a range of 200 rpm to 800 rpm

depending on air movement requirements.

The fan on-board VFI will automatically limit fan speed if fan load

current reaches operating limits.

Crankcase Heater

Some equipment has a crankcase heater band installed around the

compressor case near the bottom of the compressor. The heater is

energized when the outdoor ambient temperature drops below 65°F and

is de-energized when the outdoor ambient temperature goes above 85°F.

This prevents liquid refrigerant from accumulating in the compressor by

ensuring that the compressor is not the coldest part of the system. The

crankcase heater operates independently of indoor equipment and

Evolution Control and functions as needed any time the outdoor

equipment is powered.

CONTROL SUB-SYSTEM

The control sub-system provides the connection point for low voltage

field communication and control wiring. The control sub-system

controls all operation of the equipment.

Primary Control Module (PCM)

The PCM is the heart of the equipment control system. The PCM is the

connection point for all control components except for the high pressure

switch and the crankcase heater.

The PCM receives equipment control requests from a communicating

Evolution Control or from a non-communicating control (traditional

thermostat) in an emergency operating mode.

The PCM receives signals from numerous sensors, including:

• 4 thermistors: OAT, OCT, OST, PDT

• 2 pressure transducers: SPT, DPT.

The PCM controls numerous actuators and signals, including:

• 3 control solenoids: PEV, RVS and LLS

• 2 electronic expansion valves: EXV-H, EXV-VI

• VFD Control Interface

• Emergency Mode 24VAC Control Signals: O and W

The PCM performs numerous diagnostics and supports 120 diagnostic

codes. Each of these codes is described in the Troubleshooting section.

Diagnostics cover the following:

• Line voltage and communication

• Equipment configuration (model plug, etc.)

• Compressor and fan operation

• Sensors

• Actuators

The PCM contains indicators and displays to provide operating status

and conditions. The PCM also supports communication with the Bryant

Service Tech App through the Bluetooth Module which provides

detailed diagnostic information and reprogramming capability.

Control Connection (Communicating and

Non-Communicating)

The primary system control interface for the PCM is the communicating

Evolution Control. The PCM also supports traditional 24VAC discrete

control signals in an emergency mode of operation when a

communicating control is not available.

Communicating

Evolution

Control

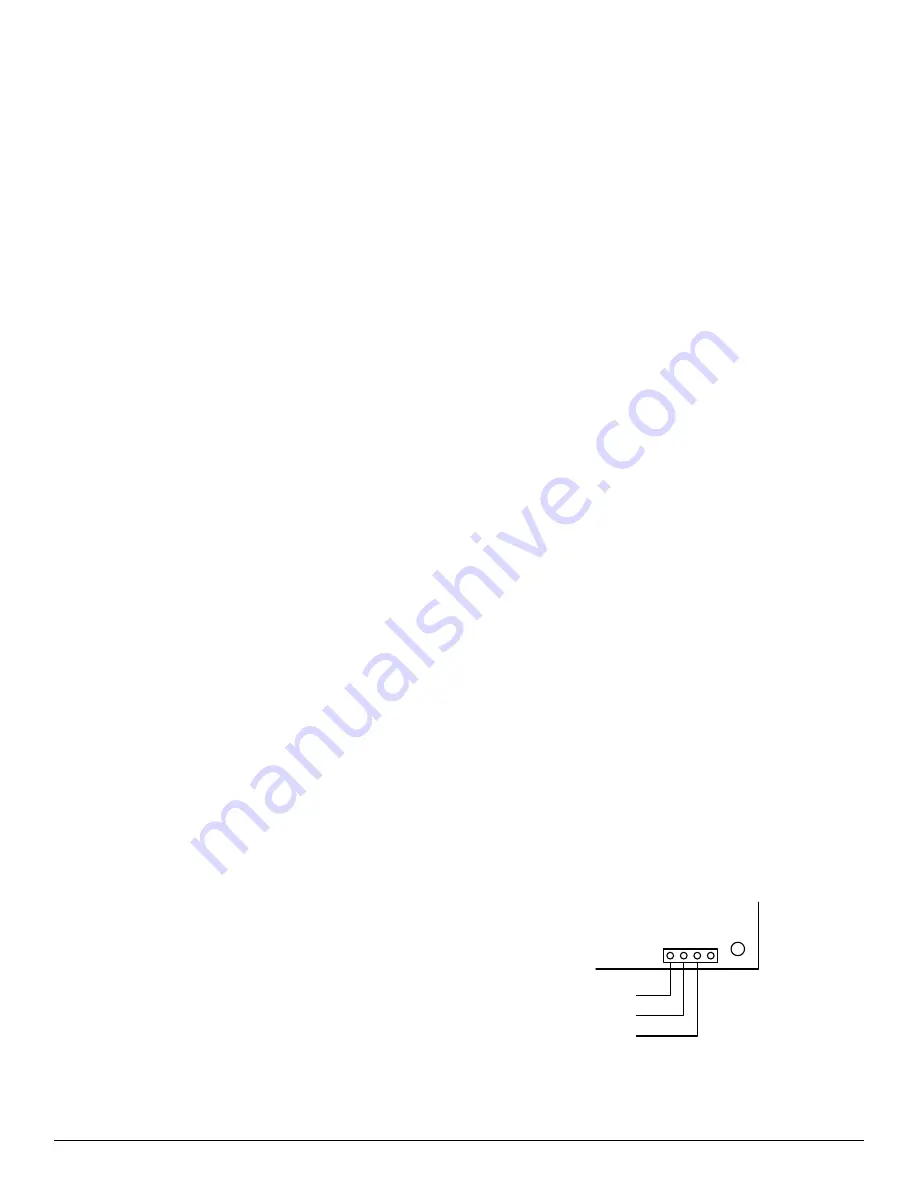

The communicating Evolution Control uses a 2-wire connection as

shown in

and Fig. 4. An optional 3rd wire can be added for a

ground connection. The third wire is recommended for long

communication runs or if there are problems encountered with consistent

communication using a 2-wire setup. The Comm light indicates whether

communication is being received from a system control.

A200239

Fig. 4 – Evolution Control Connection

A B C

A

B

GND

(oponal)