186CNV / 284ANV: Service Manual

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

11

TROUBLESHOOTING

TROUBLESHOOTING CONTROL FEATURES

Diagnostics Display

Any active diagnostics will be continuously displayed on the matrix

display. Please refer to PCM Indicators and Display Operation in the

Control Features and Operation section for further information.

Multi-Function Forced Defrost Input (J3)

The forced defrost pins are located near the right edge of the PCM

slightly above center, between two connectors. The Forced Defrost

input has the following functions:

• Forcing Defrost

• Overriding the Compressor Protect Delay

• Activating the Diagnostic Code Recall Function

These multiple functions are available at the PCM header only. The

Forced Defrost function on the Evolution Control provides only the

Defrost Forcing function. Each of these functions is described below.

Forced Defrost

A Forced Defrost event will begin when the Forced Defrost header pins

are shorted for 5 seconds while the following conditions apply:

• The equipment is operating in Heating Mode (compressor is running)

• A defrost cycle is not already in progress

The defrost event will begin with a change in compressor speed followed

by actuation of the reversing valve. For more information on the Defrost

Process, refer to Defrost Mode under Control Features and Operation

section.

Compressor Protect Delay Override

The Compressor Protect Delay will be overridden allowing immediate

equipment start when the Forced Defrost header pins are shorted for 1

second while the equipment is not operating (compressor is off).

The override condition will be confirmed with the word OVERRIDE

scrolled across the matrix display until the compressor starts. Note that

the compressor will not attempt to start unless a demand is present, and

until pressure equalization is complete (if necessary) and the fan has

successfully started.

Diagnostic Code Recall

The Diagnostic Code Recall mode will be enabled if the Forced Defrost

pins are shorted when power is applied to the equipment. It is not

possible to enter Diagnostic Code Recall mode while power is applied to

the equipment. The recommended procedure is to remove power from

the equipment, apply a clip wire between the Forced Defrost header pins

and then apply power to the equipment.

While in Diagnostic Code Recall mode, the Display Matrix will scroll

the word RECALL followed by the most recent, highest priority

diagnostic code if that code occurred with the last 240 hours of

equipment operation. The display will repeat continuously while recall

mode is active. No code will be displayed if the most recent, highest

priority diagnostic code occurred more than 240 hours of equipment

operating time before entering recall mode. No code will be displayed if

there have never been any diagnostic codes active. If there is no code to

display, then only the word RECALL will be scrolled across the display

while the mode is active.

The equipment will not operate while the Diagnostic Code Recall mode

is active.

The equipment will exit Diagnostic Code Recall mode when the short is

removed from the Forced Defrost header pins, or 15 minutes after power

is applied to the equipment if the short is still present. Upon exiting

recall mode, the recall code display will stop, any active codes will begin

to be displayed, and the equipment will resume normal operation.

SYSTEM DIAGNOSTICS

24VAC Power Distribution

IMPORTANT:

The 24VAC power (Rc) in the PCM comes from the

transformer in the equipment. The phase of this transformer connection

is not controlled relative to the phase of the power provided by the

transformer in the indoor equipment (Rh). Wiring requirements in this

manual do not connect Rc and Rh together. For any non-standard

wiring, care should be taken to make sure that Rc and Rh are not

connected together. Doing so may result in destroying one or both of the

transformers in this and the internal equipment.

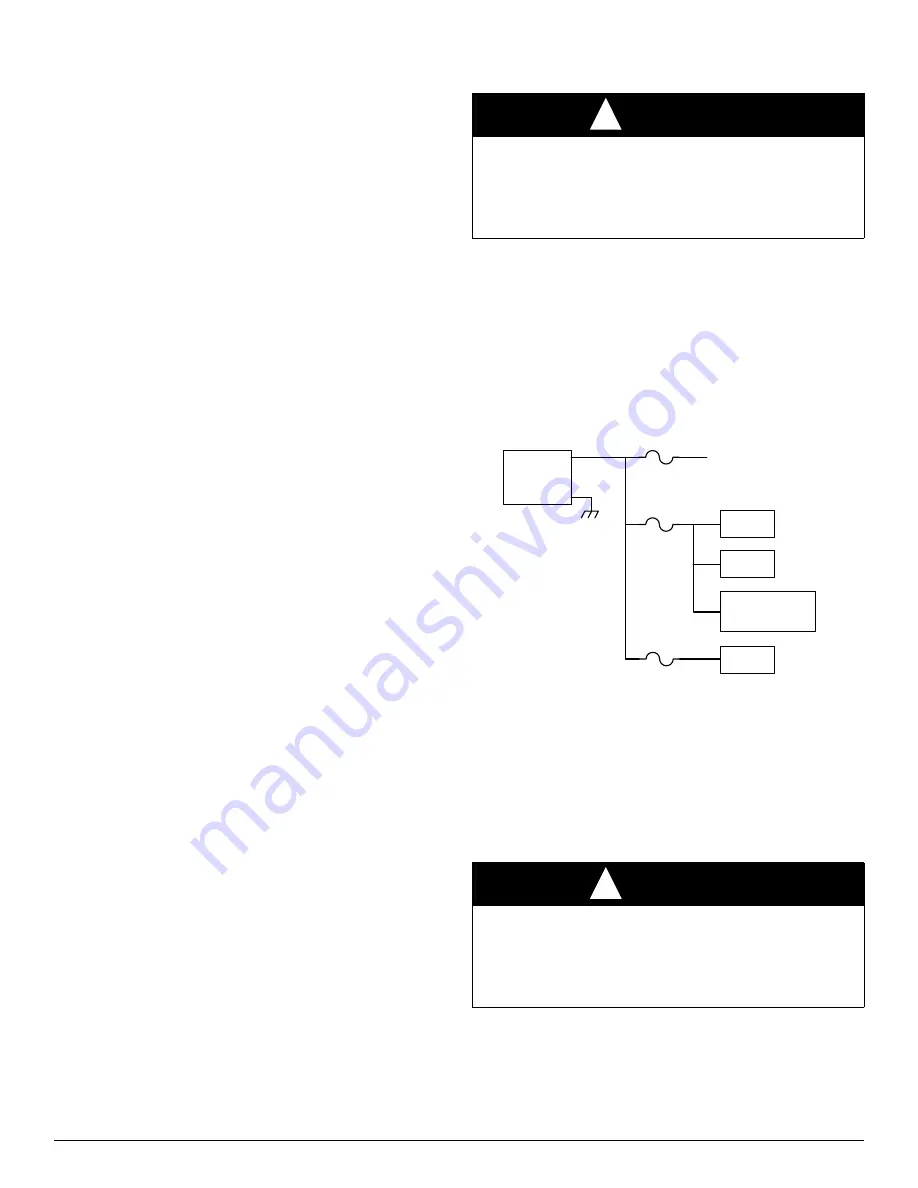

The transformer in the equipment provides power to the PCM and

numerous control components in the equipment. The power distribution

and fuse connections for this power distribution are shown in

A200252

Fig. 10 – 24VAC Power Distribution Diagram

Communication

If communication with the Evolution Control is lost, this will be

indicated by the Comm light being off. There is no diagnostic fault

associated with this condition. When communication with the Evolution

Control is lost, the equipment will default to the discrete control inputs

for operation. Refer to Control Connection in the Control Sub-System

section for further information.

Equipment Configuration (Model Plug)

Each control board contains a model plug. The model plug is used to

identify the type and size of equipment to the control. The correct model

plug must be installed for the system to operate properly (see

).

Refer to Equipment Configuration in the Control Features and Operation

section for further information.

CAUTION

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not connect the equipment 24VAC supply (Rc) to the indoor

equipment 24VAC supply (Rh).

CAUTION

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not attempt to operate system with incorrect model plug as this

could cause equipment damage.

TRANS

FORMER

PEV

Bluetooth

£

Module

FUSE1

FUSE2

MAIN PCM POWER

MAIN

FUSE

RVS

LLS

R

C