CHAPTER 4 STRUCTURE OF SYSTEM COMPONENTS

4-22

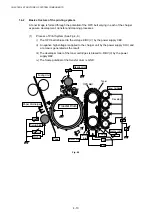

9 Drum

Cleaning

The drum cleaning process is where the residual toner on the transfer drum is removed.

(1)

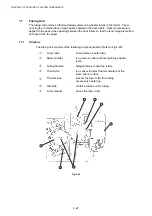

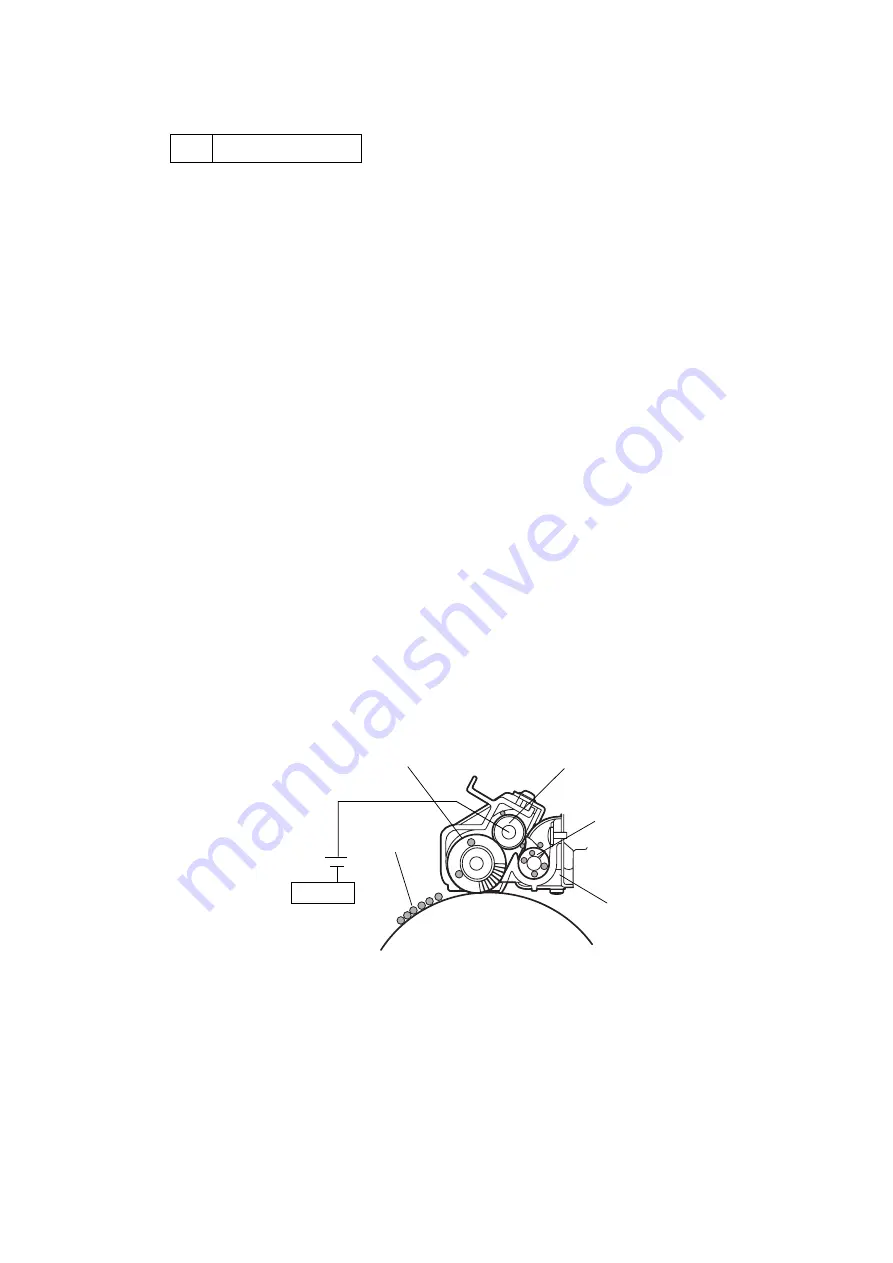

Structure of Drum Cleaning (Refer to Fig.4-23.)

i) The drum cleaning unit is located as shown in Fig.4-8.

ii) The drum cleaning brush is a semiconductor type so that the brush can clean the

surface of the rotating transfer drum. The Drum cleaning brush is kept out of

contact with the transfer drum when the print image on the transfer drum is being

created.

iii) The drum cleaning roller is positively biased by the positive voltage FCBV (V).

iv) FCBV (V) is fed to the cleaning brush in contact with the roller and the cleaning

brush is self-biased by the resistance of the brush.

v) The drum cleaning roller rotates in contact with the drum cleaning brush.

(2)

Process of Drum Cleaning (Refer to Fig.4-23.)

i) There is residual toner on the surface of the transfer drum after the paper transfer

process.

ii) The Drum cleaning brush is positively self-biased and so the negatively charged

residual toner is removed from the surface of the transfer drum onto the drum

cleaning brush.

iii) The Drum cleaning roller has been biased to the positive voltage FCBV (V). As the

cleaning brush rotates, the residual toner absorbed into the brush from the transfer

drum is attracted by the positive FCBV (V) voltage on the roller and adheres to the

surface of the drum cleaning roller.

iv) Waste toner adhering to the surface of the drum cleaning roller is scavenged by the

cleaning blade and collected into the waste toner pack by the waste toner feeder.

FCBV

Fig. 4-23

FCBV: Cleaning roller

Power supply for

fuser cleaner bias

Transfer drum

Drum cleaner

West toner feeder

Drum cleaning unit

Cleaning brush

Residual

Toner

Summary of Contents for HL-3450CN Series

Page 15: ...HL 3450CN SERVICE MANUAL xiii 3 Rating Label For US For Europe 4 Operation Label 5 Jam Label ...

Page 17: ...HL 3450CN SERVICE MANUAL CHAPTER 1 PRODUCT OUTLINE ...

Page 27: ...HL 3450CN SERVICE MANUAL CHAPTER 2 SPECIFICATIONS ...

Page 39: ...CHAPTER 3 INSTALLATION ...

Page 54: ...HL 3450CN SERVICE MANUAL CHAPTER 4 STRUCTURE OF SYSTEM COMPONENTS ...

Page 104: ...HL 3450CN SERVICE MANUAL 4 51 Main PCB Circuit Diagram 1 8 CODE B512137CIR 1 8 LJ8907001 NAME ...

Page 106: ...HL 3450CN SERVICE MANUAL 4 53 Main PCB Circuit Diagram 3 8 CODE B512137CIR 3 8 LJ8907001 NAME ...

Page 108: ...HL 3450CN SERVICE MANUAL 4 55 Main PCB Circuit Diagram 5 8 CODE B512137CIR 5 8 LJ8907001 NAME ...

Page 110: ...HL 3450CN SERVICE MANUAL 4 57 Main PCB Circuit Diagram 7 8 CODE B512137CIR 7 8 LJ8907001 NAME ...

Page 126: ...HL 3450CN SERVICE MANUAL CHAPTER 5 CONTROL PANEL OPERATION ...

Page 173: ...HL 3450CN SERVICE MANUAL CHAPTER 6 PERIODIC MAINTENANCE ...

Page 208: ...CHAPTER 7 DISASSEMBLY RE ASSEMBLY ...

Page 264: ...HL 3450CN SERVICE MANUAL CHAPTER 8 TROUBLESHOOTING ...

Page 310: ...HL 3450CN SERVICE MANUAL 8 47 5 IMAGE FAILURE 1 2 3 4 5 6 7 8 9 a 9 b 10 11 12 13 14 ...

Page 311: ...CHAPTER 8 TROUBLESHOOTING 8 48 15 a 15 b 16 17 18 19 20 21 22 23 24 25 26 27 28 244m m 29 ...