Confidential

9-4

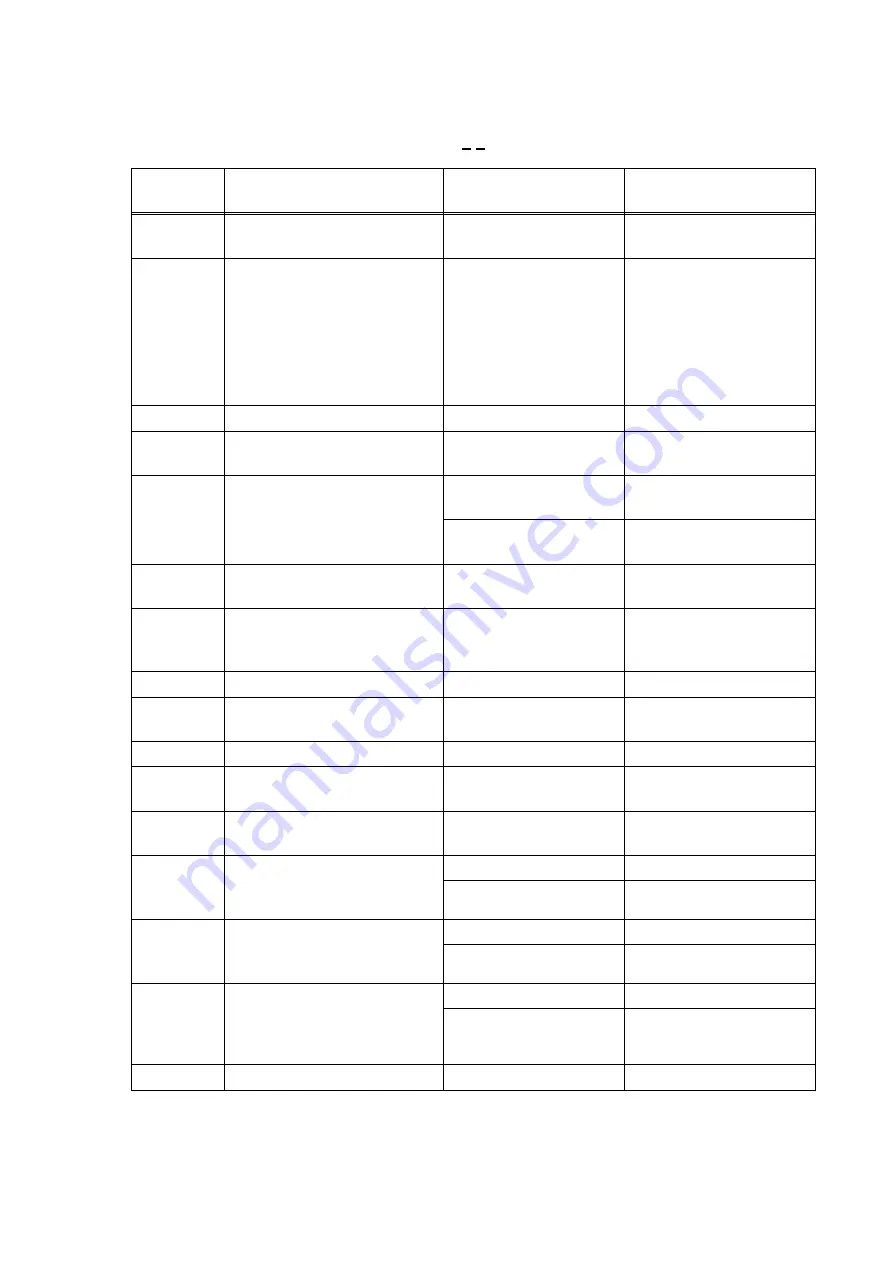

9.1.1.2 Error codes shown in the "MACHINE ERROR X X" message

Error Code

(Hex)

Symptom Probable

Cause

Solution

56

The fuser cover is opened.

The fuser cover is

opened.

Close the fuser cover.

57

Duplex jam

- Paper is remained.

- Main PCB defective

- Duplex reverse gear

damaged

- Duplex solenoid

defective

- Remove the jammed

paper.

- Replace the main PCB.

- Replace the duplex

reverse gear.

- Replace the duplex

solenoid.

58, 59

Not used.

5A

High-voltage power supply

PCB malfunction

High-voltage power

supply PCB malfunction

Replace the High-voltage

power supply PCB.

New toner actuator

lever broken

Replace the new toner

actuator.

5B

New toner sensor lever error

(New toner sensor stays on)

New toner sensor

defective

Replace the new toner

sensor.

5C

Optional lower tray

(LT-5300) error

Two or more optional

lower trays are installed.

Install one optional lower

tray.

5D

Duplex printing cannot be

implemented.

Close the rear cover of the

machine and put the

duplex tray back in.

5E, 5F

Not used.

60

Recording paper is stacked

too much in the eject section.

Stacker sensor defective

Replace the stacker

sensor.

61-67 Not

used.

68

Side thermistor high

temperature error

Side thermistor short

circuit

Replace the side

thermistor.

69

Side thermistor low

temperature error

Side thermistor break

Replace the side

thermistor.

Thermistor defective

Replace the thermistor.

6A

Heater warming-up timeout

error. (Heater does not reach

60

˚

С

w

ithin 12 second.)

Halogen lamp defective

Replace the halogen lamp.

Thermistor defective

Replace the thermistor.

6B

Heater warming-up timeout

error. (Heater does not reach

100

˚

С

w

ithin 9 second.)

Halogen lamp defective

Replace the halogen lamp.

Thermistor defective

Replace the thermistor.

6C

Heater temperature exceeds

the maximum high

temperature. (270

˚

С

or more

is detected for 1sec.)

Power supply PCB

defective

Replace the power supply

PCB.

6D Not

used.

Summary of Contents for DCP 8060

Page 19: ...Confidential CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 28: ...Confidential CHAPTER 2 SPECIFICATIONS ...

Page 65: ...Confidential CHAPTER 3 THEORY OF OPERATION ...

Page 92: ...Confidential CHAPTER 4 TRANSFER OF DATA LEFT IN THE MACHINE TO BE SENT FOR REPAIR ...

Page 95: ...Confidential 4 2 Cover page sample End page sample ...

Page 96: ...Confidential CHAPTER 5 DISASSEMBLY REASSEMBLY AND LUBRICATION ...

Page 246: ...Confidential CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS REPLACEMENT ...

Page 292: ...Confidential CHAPTER 7 CLEANING ...

Page 294: ...Confidential CHAPTER 8 MAINTENANCE MODE ...

Page 302: ...8 7 Confidential For white and black scanning a b c d e f g h i j ...

Page 314: ...8 19 Confidential Cover page sample End page sample Fig 8 10 ...

Page 323: ...Confidential CHAPTER 9 ERROR INDICATION AND TROUBLESHOOTING ...

Page 458: ...B Power Supply PCB 100V Confidential ...

Page 459: ...B Power Supply PCB 200V Confidential ...

Page 495: ...January 06 SM FAX049 8C5B03 9 Printed in Japan ...