3-3

Confidential

3.

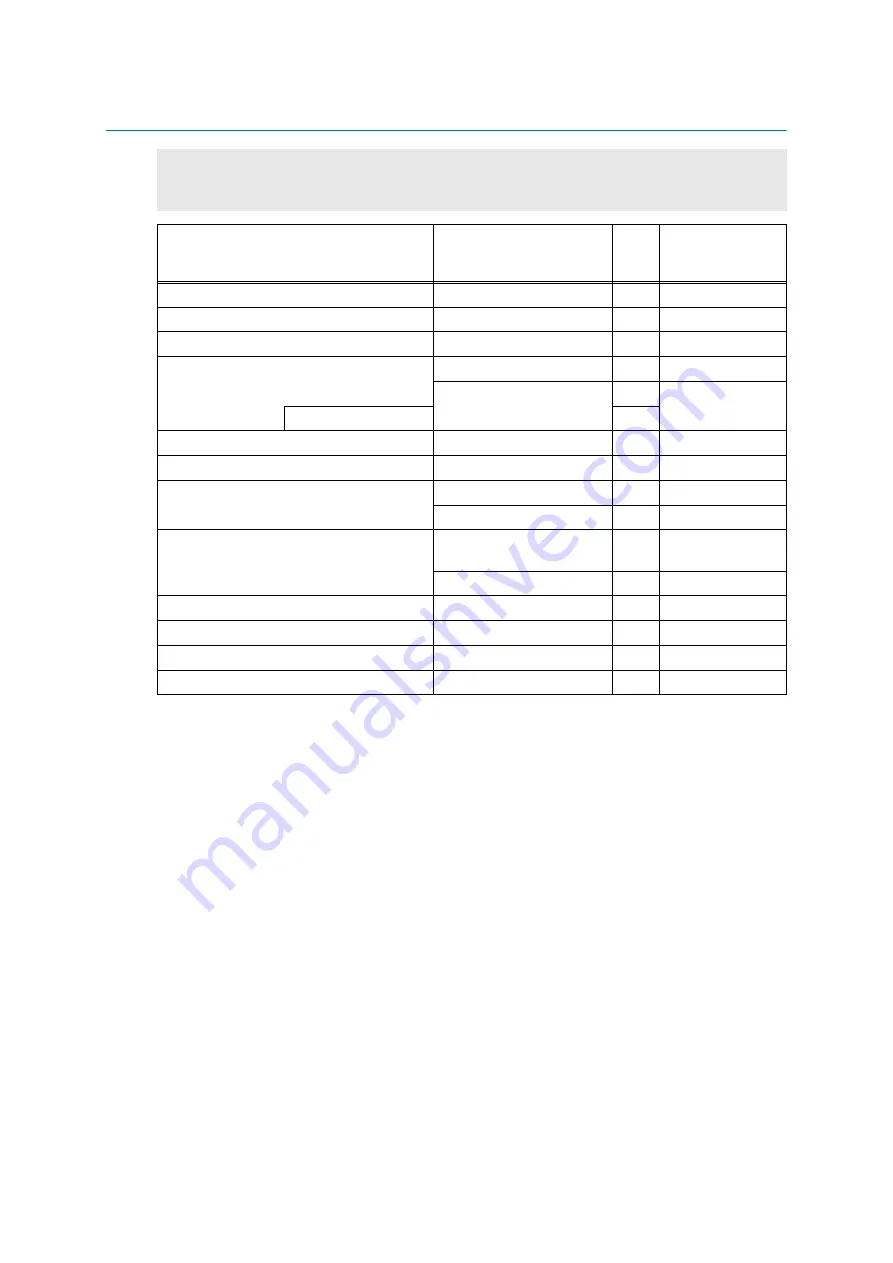

SCREW TORQUE LIST

Note:

• For verifying the shape of each screw, refer to

in this chapter.

Location of screw

Screw type

Q'ty

Tightening

torque

N·m (kgf·cm)

Bottom plate

Taptite cup S M3x5

2

0.70

0.10 (7

1)

Side cover L

Taptite bind B M3x8

1

0.50

0.10 (5

1)

Side cover R

Taptite bind B M3x8

1

0.50

0.10 (5

1)

Main PCB ASSY

Taptite cup S M3x5

3

0.70

0.10 (7

1)

Taptite bind B M3x8

1

0.50

0.10 (5

1)

Panel FG harness

1

Second side CIS FG harness

Taptite cup S M3x5

1

0.70

0.10 (7

1)

Panel unit

Taptite bind B M3x8

2

0.50

0.10 (5

1)

Pinch roller support plate

Taptite bind B M3x8

2

0.50

0.10 (5

1)

Taptite cup S M3x5

2

0.70

0.10 (7

1)

Main motor

Screw pan (S/P washer)

M3x6 DA

1

0.50

0.10 (5

1)

Taptite bind B M3x8

1

0.50

0.10 (5

1)

Gear hold plate

Taptite bind B M3x8

2

0.50

0.10 (5

1)

Cover switch ASSY

Taptite bind B M3x8

1

0.50

0.10 (5

1)

Main motor earth plate

Taptite bind B M3x8

1

0.50

0.10 (5

1)

Main PCB holder

Taptite bind B M3x8

1

0.50

0.10 (5

1)