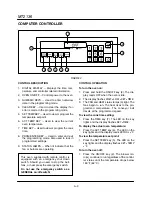

MT2136

3-17

MT2136G DOMESTIC WITH CLOSED LOOP COMPUTER CONTROL - M7287 REV A

COMPONENT REFERENCE

NOTE: Refer to FIGURE 10 page 3-31 for compoĆ

nent locations.

1. COMPUTER (FW525)

2. BELT STOP RELAY (22672)

3. BLOWER RELAY (22672)

4. HEAT RELAY (22672)

5. DC SPEED CONTROL BOARD (M2379)

6. SPST THERMAL SWITCH (M1362)

7. HIGH LIMIT SWITCH (M3295)

8. 120/24 VAC STEP DOWN TRANSFORMER

(M2352)

9. COMBUSTION MOTOR (M0767)

10. CENTRIFUGAL SWITCH

11. IGNITION MODULE (M1054)

12. PILOT VALVE (LP - 22190, Natural - M5495)

13. BURNER VALVE (LP - 22190,

Natural - M5495)

14. MOTOR CONTACTOR (M0708)

15. CONVECTION FANS (Clockwise - M2871,

CounterĆclockwise - M2870)

16. SPDT THERMAL SWITCH (M2453 L140-20F)

17. COOLING FAN (M2469)

18. RTD PROBE (M7427)

19. VDC MOTOR (M2378)

20. HALL EFFECT PICKUP (M0984)

21. COOLING FANS (M2469)

22. SPDT THERMAL SWITCH (M2453 L140-20F)

OPERATION

1. Apply power to the oven. Program the time and

temperature into the computer (1). The belt

stop relay (2), blower relay (3) and the heat

relay (4) energize powering up the oven.

2. When the belt stop relay closes, 120 VAC goes

to the DC speed control board (5) and one terĆ

minal of a N.C. SPST thermal switch (6). If the

thermal switch is closed, 120VAC is sent to the

common terminal of a manual resettable hi limĆ

it switch (7). The high limit switch is a bulb and

capillary style switch. It reacts when the oven

cavity temperature exceeds the high limit proĆ

grammed into the cooking computer.

NOTE: The single pole single throw N.C. therĆ

mal switch is a high limit device located

between the two blowers in the rear

convection fan compartment. This

switch opens when the temperature

passing its face exceeds the rating on

the back of the switch and closes when

there is a 10Ć20

5

drop in temperature

across the face of the switch.

If the high limit switch is closed power flows to

the primary side of a 115/24 volt step down

transformer (8) and the combustion motor (9)

of the flame blower. The combustion motor

powers up. When the combustion motor

reaches full speed, a centrifugal switch (10)

closes sending 24 VAC to the ignition module

(11). After the module's self diagnostics are

complete, the pilot valve ) opens. When a proof

of flame is established the main burner valve

(13) powers up.

3. The blower relay (3) sends 115 volts to the coil

of the motor contactor (14) starting the two conĆ

vection fans (15) in the rear of the oven. Power

is also applied to the N.C. terminal of a SPDT

thermal switch (16). The switch toggles if the

temperature passing its face exceeds the rating

on the back of the switch and may start the fans

even if the oven is off. If this switch is cold, it

should be made between common and N.C. terĆ

minals sending power to the cooling fan (17).

NOTE: The SPDT thermal switch is located in

the cooking computer control compartĆ

ment.This switch toggles when the temĆ

perature passing its face exceeds the

rating on the back of the switch and

Summary of Contents for MT2136 Series

Page 4: ...INTRODUCTION CHAPTER 1 ...

Page 15: ...MT2136 1 11 35 30 35 29 39 28 38 33 34 31 37 36 26 27 32 EXTERIOR COMPONENTS FIGURE 3 ...

Page 17: ...MT2136 1 13 CE GAS BURNER COMPONENTS Control Box not Shown 16 17 FIGURE 5 ...

Page 19: ...MT2136 1 15 This page intentionally left blank ...

Page 20: ...ASSEMBLY CHAPTER 2 ...

Page 23: ...MT2136 2 3 This page intentionally left blank ...

Page 24: ...OPERATION CHAPTER 3 ...

Page 49: ...MT2136 3 25 16 17 18 19 20 21 12 13 13 13 4 7 15 3 2 1 14 8 9 10 6 11 5 5 FIGURE 4 ...

Page 50: ...OPERATION 3 26 16 17 20 19 18 15 3 12 13 13 13 4 14 7 1 2 8 9 10 6 11 5 5 FIGURE 5 ...

Page 53: ...MT2136 3 29 1 17 3 2 4 16 16 16 15 21 5 13 14 14 10 18 19 6 7 8 20 9 12 11 FIGURE 8 ...

Page 54: ...OPERATION 3 30 1 18 16 16 16 16 17 15 22 5 3 2 4 13 10 19 20 6 7 8 21 9 12 11 14 14 FIGURE 9 ...

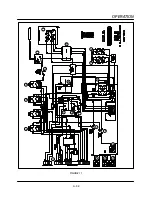

Page 55: ...MT2136 3 31 1 21 21 21 17 16 22 18 20 19 14 3 2 4 11 6 13 12 15 10 7 8 9 5 FIGURE 10 ...

Page 56: ...OPERATION 3 32 1 8 8 8 8 6 7 16 15 17 18 3 2 4 11 5 9 9 12 13 14 FIGURE 11 ...

Page 57: ...MT2136 3 33 1 6 9 8 19 22 21 7 16 17 2 3 4 18 5 10 14 20 12 11 13 15 25 25 25 24 FIGURE 12 ...

Page 58: ...OPERATION 3 34 1 FIGURE 13 ...

Page 60: ...CALIBRATION AND ADJUSTMENT CHAPTER 4 ...

Page 77: ...MT2136 4 17 This page intentionally left blank ...

Page 78: ...TROUBLESHOOTING CHAPTER 5 ...

Page 86: ...TECHNICAL APPENDIX CHAPTER 6 ...