MT2136

4-3

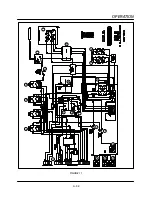

STANDARD CONTROLLER CONFIGURATION

BELT SPEED CALIBRATION - OPEN LOOP

NOTE: The following procedures must be perĆ

formed after dc voltage levels have been

set and are known to be accurate.

The cooking time digital display should be adĆ

justed when changing any of the system compoĆ

nents. Prior to adjusting the display, determine the

following two specifications:

1.

The number of pulses per spindle revoluĆ

tion generated by the Hall effect pickup.

Move the plastic endĆcaps on the pickup loĆ

cated on the DC motor. If the pickup is marked

with the number 2, it is a single pulse per revoĆ

lution pickup. If the pickup is marked with the

number 10 (Standard After 6Ć1Ć91) it is a five

pulse per revolution pickup. Replace the endĆ

caps.

2.

The manufacturer and the voltage rating of

the DC drive motor.

This information is embossed on the nameĆ

plate located on the motor's case.

Once the above specifications have been deterĆ

mined, perform the following calibration proceĆ

dures.

1. Remove the screws securing the cooking time

display lens cover. Remove the lens cover. If a

5 pulse pickup is used, verify that the multiplier

potentiometer is set to the x10 position (refer

to FIGURE 4 for the potentiometer location).

Cooking Time

INCREASE

DECREASE

X1

X10

Belt speed DIP switch located

behind cooking time digital display

Multiplier potentiometer located behind

cooking time digital display

For 5 pulse pickups set to x10

FIGURE 4

Set The Belt Speed DIP Switches.

Belt speed DIP switch settings are specified by the

following equations:

60Hz motors with a single pulse pickup use:

36

x Motor RPM x .275

60Hz motors with a five pulse pickup use:

36

x Motor RPM x .325

50Hz motors with a single pulse pickup

use:ą

36 x Motor RPM x .65

50Hz motors with a five pulse pickup use:

36 x Motor RPM x .325

NOTE: Refer to TABLE 3 to determine Motor RPM.

Bodine Motors

RPM

130VDC (Standard after 9/15/90)

4.2

180VDC (50Hz Only)

4.2

TABLE 3

The DIP switch summed values should match the

value obtained in the previous equation. Move the

appropriate DIP switches to OFF.

EXAMPLE: For a switch value of 73 (from the motor

formula and TABLE 3), set switches 7, 4 and 1 to

OFF since the total of these switches is 73

(64+8+1=73).

8 7 6 5 4 3 2 1

Switch Setting For A Value Of 73

128 64 32 16 8 4 2

1

OFF

Rear Of

Switch Number

Switch Value

Control

FIGURE 5

Summary of Contents for MT2136 Series

Page 4: ...INTRODUCTION CHAPTER 1 ...

Page 15: ...MT2136 1 11 35 30 35 29 39 28 38 33 34 31 37 36 26 27 32 EXTERIOR COMPONENTS FIGURE 3 ...

Page 17: ...MT2136 1 13 CE GAS BURNER COMPONENTS Control Box not Shown 16 17 FIGURE 5 ...

Page 19: ...MT2136 1 15 This page intentionally left blank ...

Page 20: ...ASSEMBLY CHAPTER 2 ...

Page 23: ...MT2136 2 3 This page intentionally left blank ...

Page 24: ...OPERATION CHAPTER 3 ...

Page 49: ...MT2136 3 25 16 17 18 19 20 21 12 13 13 13 4 7 15 3 2 1 14 8 9 10 6 11 5 5 FIGURE 4 ...

Page 50: ...OPERATION 3 26 16 17 20 19 18 15 3 12 13 13 13 4 14 7 1 2 8 9 10 6 11 5 5 FIGURE 5 ...

Page 53: ...MT2136 3 29 1 17 3 2 4 16 16 16 15 21 5 13 14 14 10 18 19 6 7 8 20 9 12 11 FIGURE 8 ...

Page 54: ...OPERATION 3 30 1 18 16 16 16 16 17 15 22 5 3 2 4 13 10 19 20 6 7 8 21 9 12 11 14 14 FIGURE 9 ...

Page 55: ...MT2136 3 31 1 21 21 21 17 16 22 18 20 19 14 3 2 4 11 6 13 12 15 10 7 8 9 5 FIGURE 10 ...

Page 56: ...OPERATION 3 32 1 8 8 8 8 6 7 16 15 17 18 3 2 4 11 5 9 9 12 13 14 FIGURE 11 ...

Page 57: ...MT2136 3 33 1 6 9 8 19 22 21 7 16 17 2 3 4 18 5 10 14 20 12 11 13 15 25 25 25 24 FIGURE 12 ...

Page 58: ...OPERATION 3 34 1 FIGURE 13 ...

Page 60: ...CALIBRATION AND ADJUSTMENT CHAPTER 4 ...

Page 77: ...MT2136 4 17 This page intentionally left blank ...

Page 78: ...TROUBLESHOOTING CHAPTER 5 ...

Page 86: ...TECHNICAL APPENDIX CHAPTER 6 ...