Copiscan 8000 Plus Series Operator Manual

www.bellhowell.imagingcomponents.com

August 25, 2000

1-800-SCAN495

33

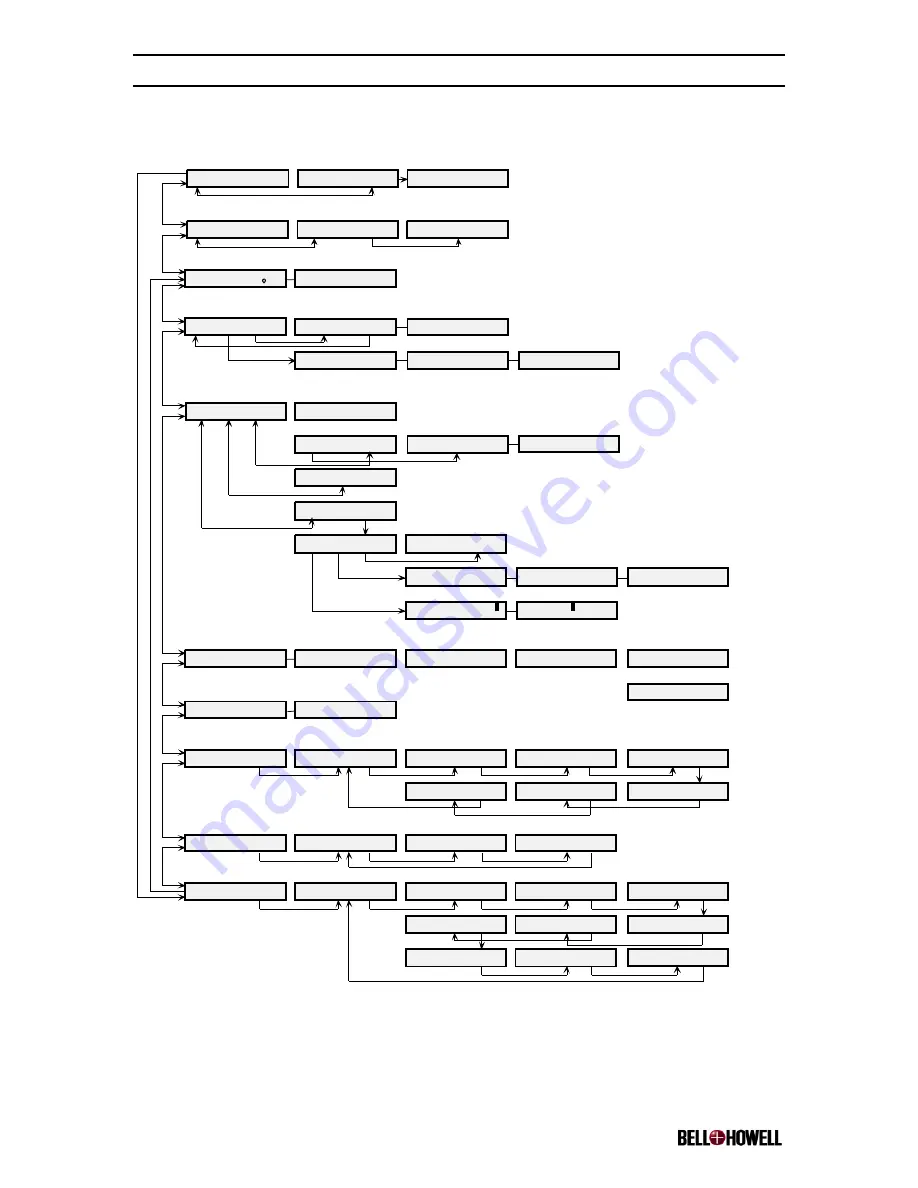

The menu below provide you with a guide for setting scanner parameters:

Ready 0000

8080D Auto Feed < >

Download new software?

Press F1 to confirm < >

Download new software

SCANNER SCSI CANCEL

Updating software...

Power cycle when done

Select Feeder Mode

ADF

*

MANUAL SETUP < >

ADF Adjustment 200dpi

START STOP

*

EXIT

ADF Adjustment 200dpi

START

*

STOP

Open feeder guides

ADF MANUAL

*

< >

Lift skimmer

ADF MANUAL

*

< >

Set knob to M

ADF MANUAL

*

< >

Front Printer:Off 100%

ON/OFF REFILL

SETUP < >

Set text to be printed

STRING

*

FONT DELAY ^

Print Delay is 1.5”

STRING FONT DELAY

*

±^

New cartridge installed?

YES CANCEL

Print on next page fed?

OK CANCEL

Feed Paper

CANCEL CLEAN

*

Cleaning imprinter...

< COPISCAN 8000

#

>

BASE

*

INDEX ON/OFF ±^

Start at <

000000>

BASE INDEX

*

ON/OFF ±^

Font Size is Large

SIZE

*

WIDTH ANGLE ±^

Font Width is Normal

SIZE WIDTH

*

ANGLE ±^

Font Rotation is 180

°

SIZE WIDTH ANGLE

*

±^

ACE Mode is Normal S5

FRONT

*

BACK MODE <±>

ACE Mode is Shipper S7

FRONT BACK

*

MODE <±>

Front Filter is White

FRONT

*

BACK <±>

Back Filter is Green

FRONT BACK

*

<±>

User Setup

NEXT < >

Multifeed Mode: Stop

NEXT <±>

SCSI Identifier: 6

NEXT <±>

SCSI Termination: On

NEXT <±>

Deskew: Enabled

NEXT <±>

Auto Balance: Disabled

NEXT <±>

Max Hole Size: 0.25”

NEXT <±>

Scanned: 244657

NEXT < >

Time On: 381hr 36min

NEXT < >

Pages Fed: 245681

NEXT < >

Code Revision Numbers

NEXT < >

Back Printer:On 100%

ON/OFF REFILL

CLEAN < >

1.87 Feb 16 2000

Scanner Rev. NEXT < >

0120

SCSI Rev. NEXT < >

3.16

Feeder Rev. NEXT < >

2.1

Front IJPM Rev. NEXT < >

2.1

Back IJPM Rev. NEXT < >

V1.04.34

Avocet Software NEXT < >

1.00

Avocet Hardware NEXT < >

1.0

Page Entry Rev. NEXT < >

1.0

Page Exit Rev. NEXT < >

Front Printer Option

Back Printer Option

Color Dropout Option

VRS Only

VRS Only

SCSI Only

SCSI Only

SCSI Only

Front Print er Option

Back Printer Option

VRS Only

VRS Only

Scanning 0234

8125D Manual Feed < >

x=

=

ACE Mode is Drop S5

FRONT BACK

*

MODE <±>

ACE Mode is Photo S5

FRONT BACK

*

MODE <±>

ACE Mode is Recog S5

FRONT BACK

*

MODE <±>

ACE Mode is No ACE S5

FRONT BACK

*

MODE <±>

Counters

NEXT < >

Doc Prep: Good

NEXT <±>

8125 Only

26.02 ISV

OI Rev. NEXT < >

Front Printer:On 100%

ON/OFF REFILL CLEAN < >

Select new model?

Press F1 to confirm < >

Select Model: 8080D

CANCEL SET ±

New model has been set.

Power cycle scanner...

ISV Select able Model Only

Figure 19. Menu Flow