5

Components and Connections

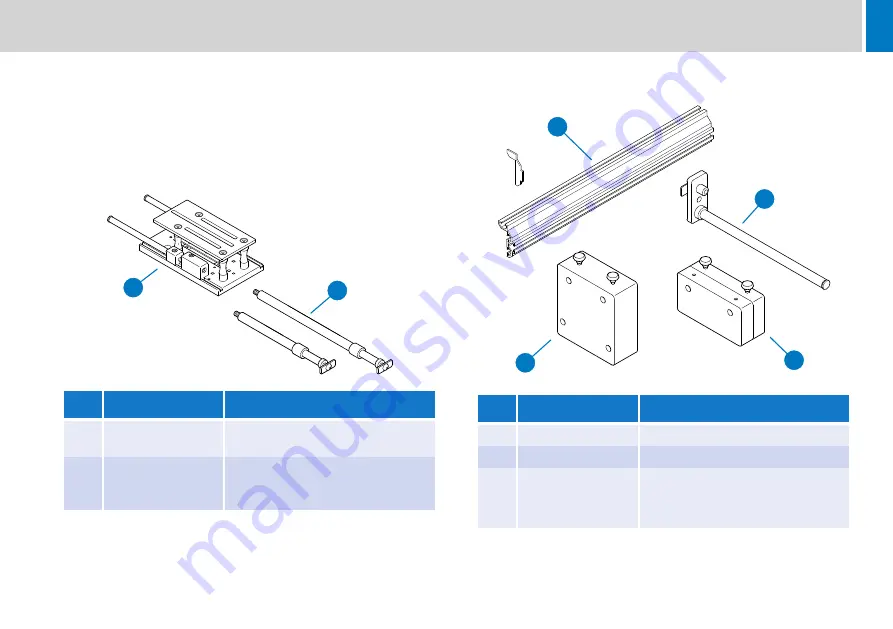

Prompter Installation Components

The following section describes the range of component parts available

for a complete prompter installation using the E.P.I.C TFT monitor.

Many of the parts listed are optional, depending on the specific

requirements of the installation.

Camera Mounting Components

*Retracted length of the rods.

Prompter Mounting Components

No.

Part

Description

1

MT-BLACK

Camera mounting plate for larger

studio camera configurations

2

TR-7, TR-12

One pair of 7 or 12 inch* telescopic

rods are required for use with the

MT-BLACK plate

1

2

x2

No.

Part

Description

3

EXT-M or EXT-L

Extrusion, medium or long

4

TFT-RDS

Prompter monitor support rods

5

CBMT-R

Counterbalance weights, 10 lb

(4.5Kg)

6

CBMT-R20

Counterbalance weights, 20 lb (9Kg)

3

4

x2

x2

6

5