TROUBLESHOOTING

36

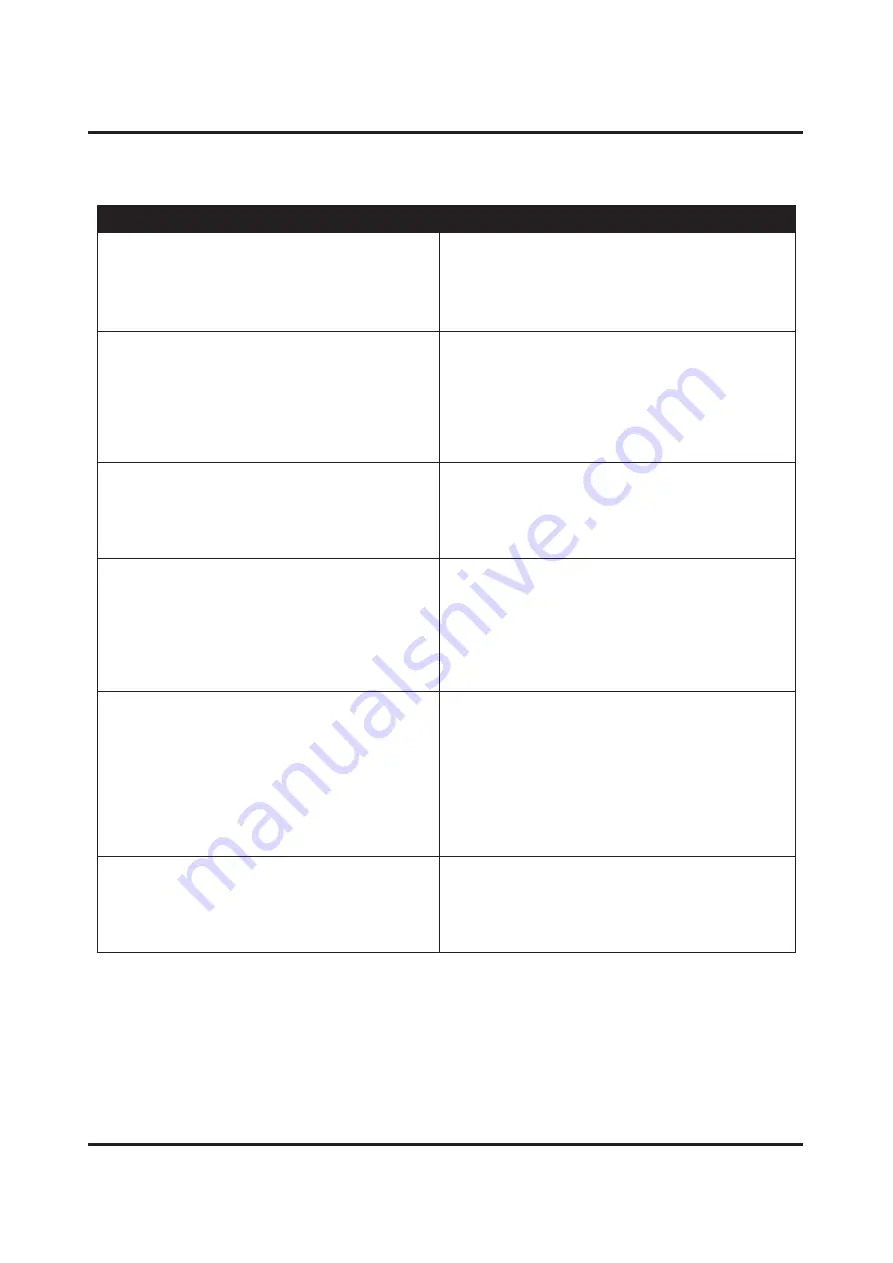

Tabber Operation Problems

CONDITION

SOLUTION

Media feeds, but no tab or stamp is applied.

1. Make sure media is feeding against the

Fixed Side Guide.

2. Check Media Sensor for proper operation.

3. Check that tabs are present. Out of tabs?

4. Check that tabs are threaded correctly.

Tabber Display powers ON, but Transport

Power Button won't turn ON when pressed.

1. Check that the Emergency Stop switch is

released.

2. Check that the Exit Roller Assembly is

closed and locked.

3. Check that Jumper Plug is installed in the

Safety Stop connection (

located on side

wall of Tabber.

)

Unwind Drive Rollers not advancing

Tabs/Stamps into Bin.

1. Check that the Power connection between

the Reel Assembly and Tabber is securely

connected.

2. Check that Unwind Rollers are engaged.

3. Check/clean Bin Sensor.

Tab web breaking at the Unwind Driver

Roller.

1. Tab Web wrapping around Rollers. Clean

Unwind Roller.

2. Tabs not spinning freely on Reel. Reel

improperly installed.

3. Check that Power connection between

Reel Assembly and Tabber is securely

connected.

Tab Web breaks at or near the Tab Applicator

Head peel point.

1. Tabs not manufactured correctly.

Tab backing cut when tabs were made; as

Tab's peel backing is torn.

Tab Web too weak.

2. Unwind Drive Rollers not advancing

Tab stock.

3. Check that power connection between

Reel Assembly and Tabber is securely

connected.

Tabber Stops while tabbing.

1. Speed of tabbing exceeds maximum

speed for the number of tabs being

applied. Slow down Tabber.

2. Feeder speed is too fast, leaving too little

gap between pieces. Slow down Feeder.