SECTION 5

TROUBLESHOOTING

73

Toolbox System Status Messages (

Continued

)

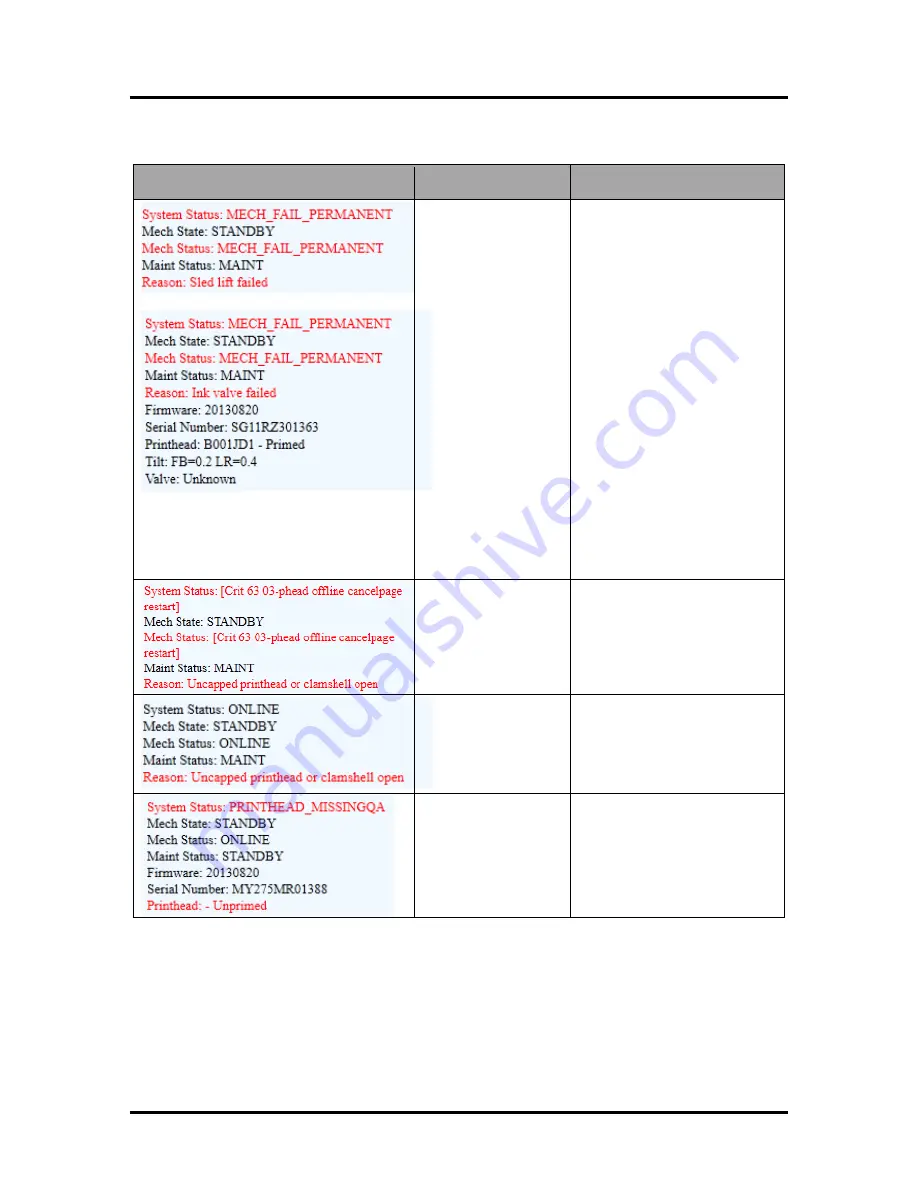

SYSTEM STATUS

SOURCE

SOLUTION

Mechanical error

One of Printer's

mechanical

components was not

properly registered at

expected position.

Mechanical failure or

Sensor failure.

Visually inspect component

stated as a

“Reason” for failure.

Using

Scan Sensors

page in

Toolbox

, perform toggle test on

Sensor responsible for

registration of failed mechanical

component position.

Lifter Arm Sensor is dirty or

damaged, Lifter Motor Cable is

unplugged, operator's side

Lifting Arm is damaged, or

Lifting Arm mechanism is stuck.

Dual Pinch Valve problem:

Check Sensor board connector

and flag/sensors alignment.

Check Valve motor connector.

Check P2005 cable on MPCA.

At this point, this error may

represent an Ink Pump error,

since there is no return signal

from pump and therefore, a

separate message describing an

Ink Pump error.

Data Cables

unplugged, dirty

Printhead contacts,

dirty PPCA contacts.

Check data cables (

P250,

P260

), clean Printhead contacts,

and/or clean PPCA contacts.

Service Station is

ejected, Service

Station position

sensors are damaged

or malfunctioning.

Check Service Station position.

Using

Scan Sensors

page in

Toolbox

, perform toggle test

on the two Sensors responsible

for registration of Service

Station position.

Printhead missing and

one or more of the Ink

Tanks are missing,

When this error

occurs, Multiple EWS

monitoring is disabled.

Install Printhead.

Install Ink Tanks.

Summary of Contents for AstroJet M2

Page 6: ......

Page 13: ...SECTION 1 GETTING ACQUAINTED 7 MORE TROUBLESHOOTING GUIDES IN SECTION 5...

Page 88: ...Feed Table Status Light Indicator Chart...

Page 89: ......