Ascon Tecnologic - KX Line - ENGINEERING MANUAL -Vr.4.0

PAG. 27

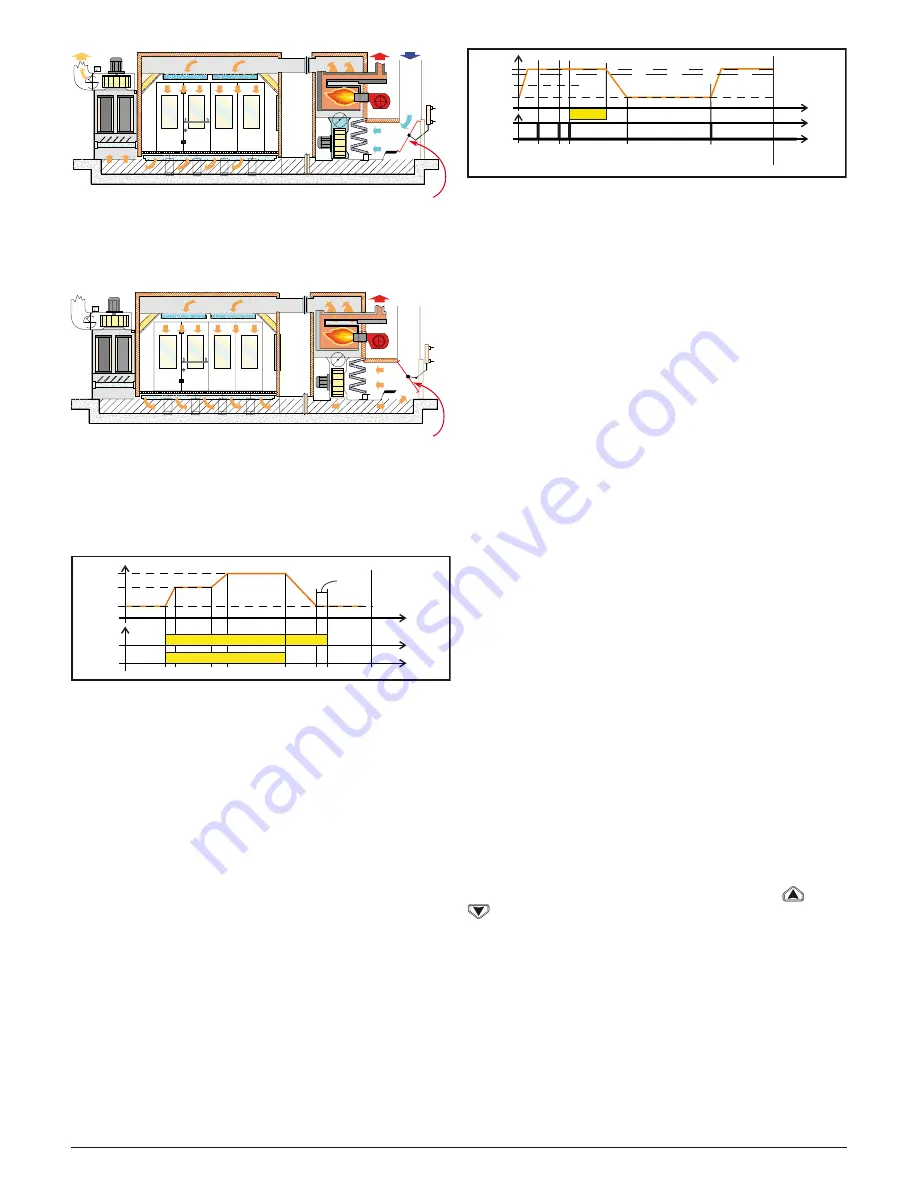

Shutter

During the passivation and drying phases, the operator is

out of the booth and the system closes the shutter of the air

and recycles the internal air in order to reduce the power

consumption.

Shutter

When the drying time is finished, before the operator is

allowed to enter into the boot, you must be sure that:

1. The air in the booth has been refreshed

The temperature is lower than a limit.

So that you need a profile like the one that follows:

Status

Run

Event 1

Event 1 = ON shutter closed

Program

OFF

OFF

Program Run

Time

Pr.S3 = 20°C

P.End

Temp.

Passivation

Drying

Pr.S2

Wait

Pr.S1

20°C

Time

Out 1 = H.rEG (heating output)

Out 2 = P.Et1 (program event 1)

Out 3 = P.run (program running)

Pr.E1and Pr.E2 = 10.10

(event 1 goes ON during ramp 1, soak 1, ramp 2 and soak 2)

When the program is running the door is locked

Application Example 2: edge bending machine with

glue tank (for wood)

At the working temperature the hot melt rapidly oxidizes and

runs down from the “dispenser”.

For this reason, when the machine does not work for a

certain time, it is suitable to move the temperature of the

dispenser to a lower value to idle.

In this cases the configuration is the following:

Out 1 = h.reg (heating output)

Out 2 = AL (alarm used to enable the dragger)

diF.1 = P.run (dig. input 1 used for Program run/restart)

Pr.F = S.uP.S (start at power up)

Pr.E = cnt (Instrument behaviour at the end of the

program execution = continue).

Connect a proximity switch to Dig. In 1 for panel detection.

Temp.

Pr.S1

Wait

Pr.S1

20°C

Time

Cl

os

ed

Dig In 1

PWR

ON

Time

Cl

os

ed

Cl

os

ed

Cl

os

ed

Pr

og

.

En

d

Pr.t1

When a new panel is detected before the end of the first

soak time, the program restarts and the set point remains

equal to Pr.S1.

If no panel is detected, the instrument goes to Pr.S2 (idle

temp) and remain there until a new panel arrives.

6.4.5 Display management

This instrument allows you to program (see parameter [124]

diS.t the time out of the display.

This function allows to turn OFF the display when no alarm

is present and no action is made on the instrument.

When [124] diS.t is different to OFF (display always ON) and

no button is pressed for more than the programmed time

out, the display goes OFF and only 4 segments of the less

significant digit are turned ON in sequence in order to show

that the instrument is working correctly.

If an alarm occurs or a button is pressed, the display will

come back to the normal operation.

6.4.6 The display colour shows the Deviation

This instrument allows to program the deviation (PV - SP) for

colour display change (see parameter [123] AdE).

In this way the upper display will be:

–

Amber when PV is lower than SP - AdE.

–

Green when (SP - AdE) < PV<SP + AdE)

–

Red when PV is higher than SP+AdE

6.5 MANuAL MODE

This operative mode allows you to deactivate automatic

control and manually program the percentage power output

to the process.

When the instrument is in manual mode, the upper display

will show the measured value while the lower display will

show alternately the power output [preceded by

H

(for

heating action) or

C

(for cooling action)] and the message

oPLo

(open loop).

When manual control is selected, the instrument will start to

operate with the same power output as the last one supplied

by automatic mode and can be modified using the

and

buttons.

In case of ON/OFF control, 0% corresponds to the

deactivated output while any value different from 0

corresponds to the activated output.

As in the case of visualization, the programmable values

range from H100 (100% output power with reverse action) to

C100 (100% output power with direct action).

Notes: 1.

During manual mode, the alarms are operative.

2.

If you set manual modes during program execution,

the program will be frozen and it will restart when

the instrument will come back to Auto mode.

3.

If you set manual modes during self-tune