Ascon Tecnologic - KX Line - ENGINEERING MANUAL -Vr.4.0

PAG. 18

as remote set point (RSP).

trin =

The value coming from serial link will be

algebraically added to the local set point

selected by A.SP and the sum becomes

the operative set point.

PErc = The value coming from serial will be scaled

on the input range and this value will be

used as remote set point.

Note:

A [83] SPrt change produces the following actions:

•

When [83] SP.rt = rSP - the remote set point

will be forced to be equal to the active set point

•

When [83] SP.rt = trin - the remote set point

will be forced to zero

•

When [83] SP.rt = PErc - the remote set

point will be forced to zero

Example:

A 6 zone reflow-oven for PCB.

The master unit sends its set point value to 5 other zones

(slave controllers).

The Slave zones use it as a set point trim.

The first zone is the master zone and it uses a set point

equal to 210°C.

The second zone has a local set point equal to -45°C.

The third zone has a local set point equal to -45 (°C).

The fourth zone has a local set point equal to -30.

The fifth zone has a local set point equal to +40.

The sixth zone has a local set point equal to +50.

In this way, the thermal profile will be the following:

–

Master SP = 210°C;

–

Second zone SP = 210 -45 = 165°C;

–

Third zone SP = 210 -45 = 165°C;

–

Fourth zone SP = 210 - 30 = 180°C;

–

Fifth zone SP = 210 + 40 = 250°C;

–

Sixth zone SP = 210 + 50 = 260°C.

Changing the SP of the master unit, all the other slave units

will immediately change their operative set point.

[84] SPLr - Local/remote set point selection

Available:

When at list one output is programmed as control

output.

Range:

Loc =

Local set point selected by [82] A.SP;

rEn =

Remote set point (coming from serial link).

[85] SP.u - Rate of rise for positive set point

change

(ramp up)

Available:

When at list one output is e programmed as

control output.

Range:

0.01... 99.99 units per minute;

inF =

ramp disabled (step transfer).

[86] SP.d - Rate of rise for negative set point

change

(ramp down)

Available:

When at list one output is e programmed as

control output.

Range:

0.01... 99.99 units per minute;

inF =

ramp disabled (step transfer).

General note about remote set point: when the remote set

point (RSP) with trim action is programmed, the local set

point range becomes the following:

from [76] SPLL+ RSP to [77] SPHL - RSP

]

tin group - Timer function parameters

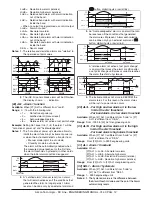

Five timer types are available:

Delayed start with a delay time and a “end of cycle” time.

Start

OUT

off

Tr.t1

Tr.t2

off

ON

–

Setting tr.t2 = Inf the timer out remains in ON condition

until a reset command is detected.

Start

OUT

ON

off

Tr.t1

Tr.t2 = inF

off

Reset

Delayed start at power up with a delay time and a “end of

cycle” time.

Start

OUT

PWR UP

off

Tr.t1

Tr.t2

off

ON

Feed-through.

Start

OUT

Tr.t1

off

Reset

ON

Asymmetrical oscillator with start in OFF.

Start

OUT

ON

off

Tr.t2

ON

off

Tr.t1

Tr.t1

Tr.t2

ON

off

Tr.t1 Tr.t2

Reset

Asymmetrical oscillator with start in ON.

Start

OUT

ON

off

Tr.t2

off

Tr.t1

Tr.t1

Tr.t2

off

Tr.t1 Tr.t2

Reset

ON

ON

Notes: 1.

The instrument can receive the start, hold and

reset commands by

button, by logic inputs

and/or by serial link.

2.

An HOLD command can suspend the time count.

[87] tr.F= Independent timer function

Available:

Always.

Range:

nonE = Timer not used

i.d.A = Delayed start timer

i.uP.d = Delayed start at power up

i.d.d = Feed-through timer

i.P.L = Asymmetrical oscillator with start in OFF

i.L.P = Asymmetrical oscillator with start in ON

[88] tr.u - Engineering unit of the time

Available:

When [87] tr.F is different form nonE.

Range:

hh.nn = Hours and minutes

nn.SS = Minutes and seconds

SSS.d = Seconds and tenth of seconds

Note:

When the timer is running, you can see the value of

this parameter but you can NOT modify it.