Ascon Tecnologic - KX Line - ENGINEERING MANUAL -Vr.4.0

PAG. 6

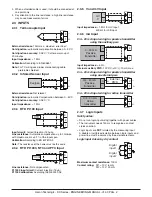

4. Using

and

buttons set the code 1 value

according to the following tables.

L M N O

Prepare your code 1

Input Type and Range

L

M

TC J

-50... +1000°C

0

0

TC K

-50... +1370°C

0

1

TC S

-50... 1760°C

0

2

TC R

-50... +1760°C

0

3

TC T

-70... +400°C

0

4

Infrared J

-50... +785°C

0

5

Infrared K

-50... +785°C

0

6

PT 100/PTC KTY81-121

-200... +850°C/-55... +150°C

0

7

PT 1000/NTC 103-AT2

-200... +850°C/-50... +110°C

0

8

Linear 0... 60 mV

0

9

Linear 12... 60 mV

1

0

Linear 0... 20 mA (this selection forces Out 4 = TX)

1

1

Linear 4... 20 mA (this selection forces Out 4 = TX)

1

2

Linear 0... 5 V

1

3

Linear 1... 5 V

1

4

Linear 0... 10 V

1

5

Linear 2... 10 V

1

6

TC J

-58... +1832°F

1

7

TC K

-58... +2498°F

1

8

TC S

-58... 3200°F

1

9

TC R

-58... +3200°F

2

0

TC T

-94... +752°F

2

1

Infrared J

-58... +1445°F

2

2

Infrared K

-58... +1445°F

2

3

PT 100/PTC KTY81-121

-328... +1562°F/-67... +302°F

2

4

PT 1000/NTC 103-AT2

-328... +1562°F/-58... +230°F

2

5

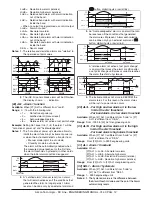

L M N O

c%d1

:

Control mode

OP1

OP2

OP3

OP4

N

O

ON/OFF heating = H

H

AL1

AL2

AL3

0

0

NU

AL1

AL2

H

0

1

ON/OFF cooling = C

C

AL1

AL2

AL3

0

2

NU

AL1

AL2

C

0

3

ON/OFF with neutral zone

(H/C)

H

C

AL2

AL3

0

4

H

AL1

AL2

C

0

5

C

H

AL2

AL3

0

6

NU

H

AL2

C

0

7

C

AL1

AL2

H

0

8

NU

C

AL2

H

0

9

PID heating = H

H

AL1

AL2

AL3

1

0

NU

AL1

AL2

H

1

1

PID cooling = C

C

AL1

AL2

AL3

1

2

NU

AL1

AL2

C

1

3

PID double action (H/C)

H

C

AL2

AL3

1

4

H

AL1

AL2

C

1

5

C

H

AL2

AL3

1

6

NU

H

AL2

C

1

7

C

AL1

AL2

H

1

8

NU

C

AL2

H

1

9

Servomotor PID heating

NU

UP

down

AL3

2

0

Servomotor PID cooling

NU

UP

down

AL3

2

1

Note:

To select the PID control mode for servodrive

(

N

plus

O

=

20

or

21

), in the order code both

Output 2

and

Output 3

codes must be selected as “

M

” (see

“How to order” pargraph).

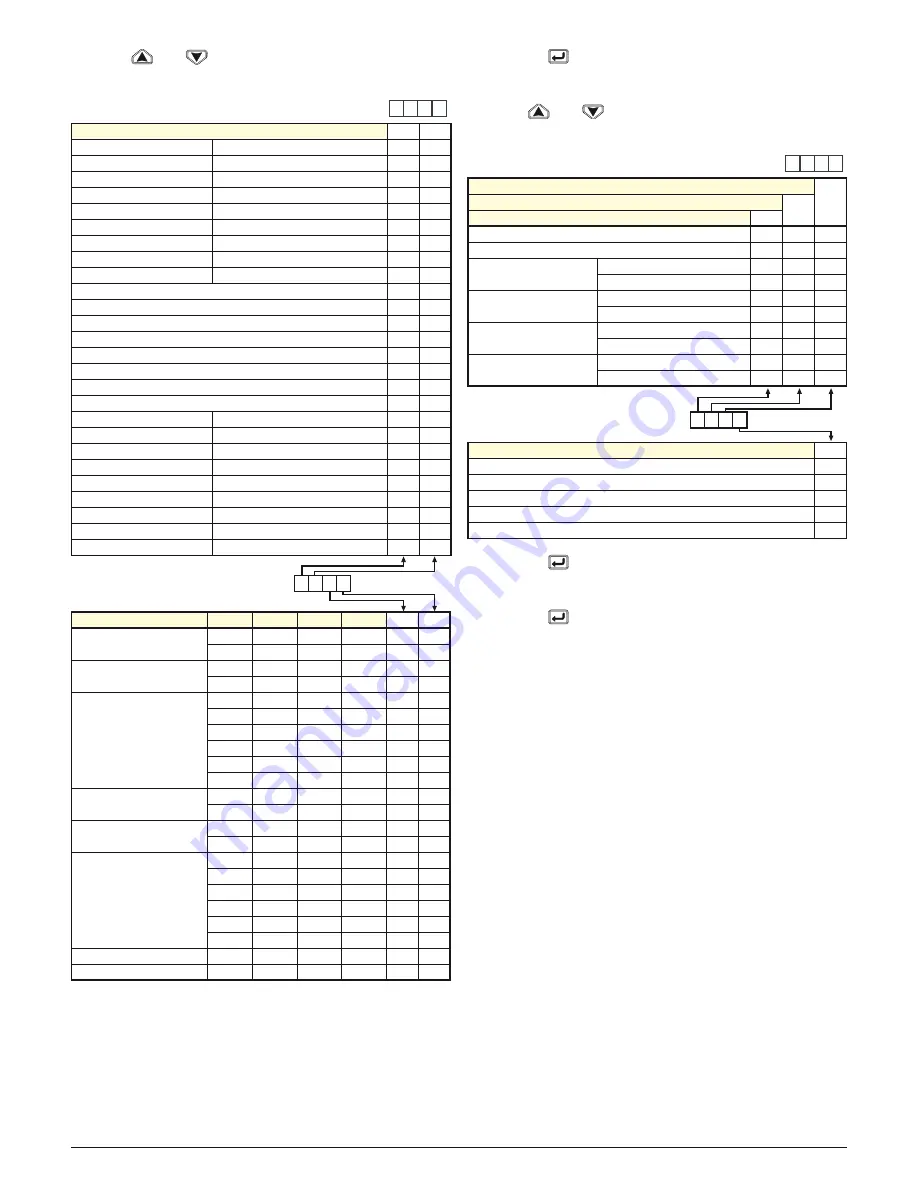

5. Push the

button.

The upper display shows

cod2

flashing while the lower

display shows

0000

or the

cod2

value stored in memory.

6. Using

and

buttons set the code 2 value

according to the following tables.

P Q R S

Prepare your code 2

Alarm 3

R

Alarm 2

Q

Alarm 1

P

Not used

0

0

0

Sensor break

1

1

1

Absolute

High

2

2

2

Low

3

3

3

Absolute High/Low

External High/Low

4

4

4

Internal High/Low

5

5

5

Deviation

Deviation high

6

6

6

Deviation low

7

7

7

Band

External band

8

8

8

Internal band

9

9

9

P Q R S

c%d2

:

Auxiliary functions activation

S

None

0

Wattmeter (instantaneous power expressed in W)

1

Wattmeter (energy expressed in Wh)

2

Absolute worked time (expressed in days)

3

Absolute worked time (expressed in hours)

4

7. Push the

button.

If the just entered codes are accepted, the upper display

shows

code

flashing while the lower display shows

good

.

8. Push the

button to save the configuration code and

exit the Code configuration procedure.

Note:

After using the “

Code configuration

” method, it will

always be possible to modify the parameters using the

“

Complete configuration

” method. If the value of a

parameter among those included in the configuration

codes (

cod1

-

cod2

) gets modified, the instrument

will acquire the change while maintaining all the other

parameters.

wARNING!

After a parameter change made as described

in the previous “

Note

”, when retrieving the

configuration codes (

cod1

-

cod2

), the lower

display will show “

oFF

” to alert the operator that

one of the parameters has been changed.