3: Configuration and Basic Operation

23

23

23

23

!

Tip:

Follow the steps

in the

for

assistance with

the Angle Align

and Reference

Frame settings.

!

Tip:

you

can also

download the

Utility by visiting

Ascension's web

site.

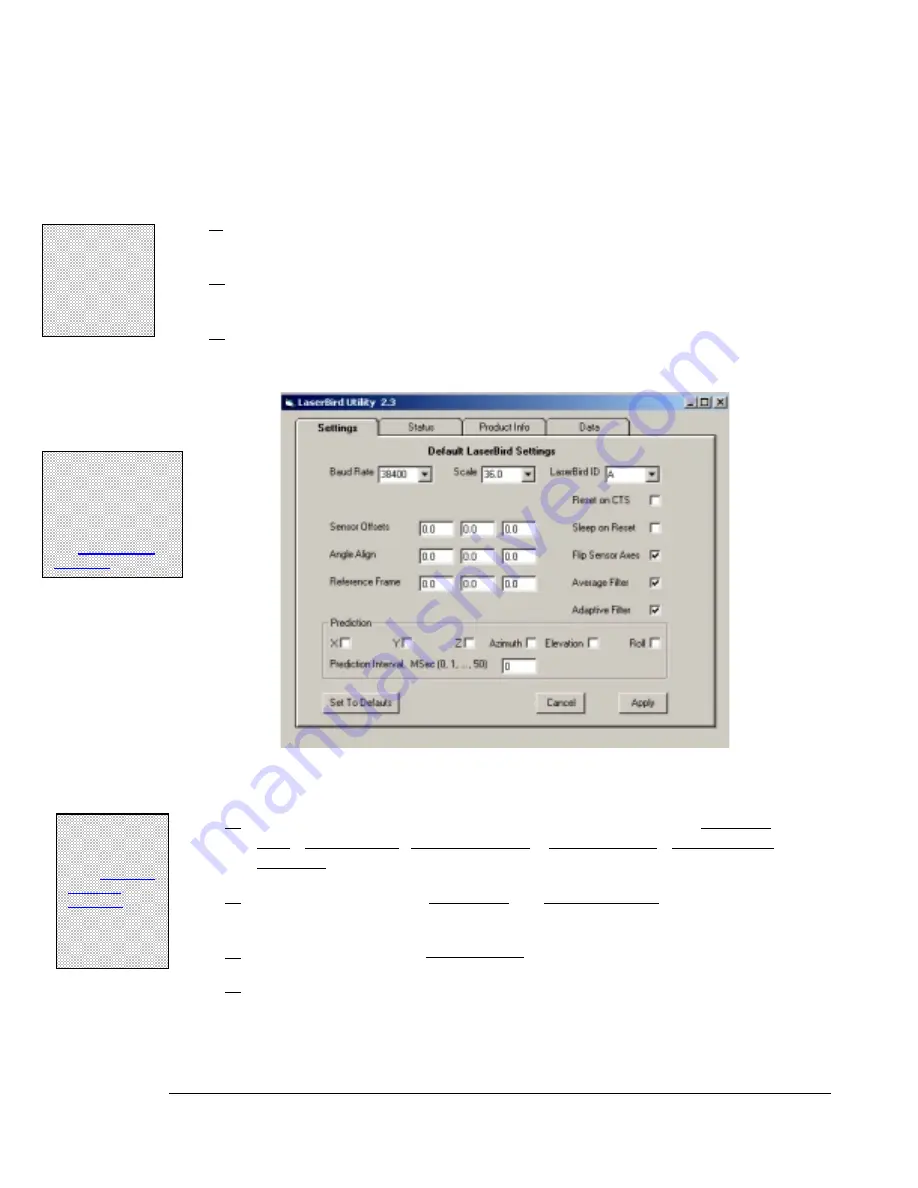

Changing Your Settings

The power-up settings are easily configured through use of the laserBIRD Utility.

1.

Make sure the laserBIRD is running, and connected to the host PC where the

utility has been installed.

2.

Start the utility by selecting

laserBIRD Utility

from the Ascension Technology

program group in the Windows® Start menu.

3.

When the utility establishes communication with the laserBIRD it will open the

main screen.

4.

Use the pull down menus and check boxes to select your desired Baud Rate,

Scale, laserBIRD ID, Flip Sensor Axes, Sleep on Reset, Reset on CTS,

Prediction, and Filter Status settings.

5.

If you've determined the Angle Align and Reference Frame settings for your

application and want to include them as defaults, enter them here in Degrees.

6.

If required, enter default Sensor Offsets for X, Y, and Z in Inches.

7.

Click

'Apply'

to download the new settings to your system's flash memory.

NOTE: Selecting the 'Set to Defaults' option (and clicking

'Apply') will restore the factory installed settings.

!

Note:

For Dual

Scanner operation,

remember to check

the laserBIRD

ID

settings in both units.

See

.

Summary of Contents for laserBIRD

Page 3: ......

Page 5: ......

Page 7: ......

Page 11: ......

Page 21: ......

Page 32: ...3 Configuration and Basic Operation 25 25 25 25 Figure 3 3 Sensor Mounting Dimensions inches...

Page 42: ...3 Configuration and Basic Operation 35 35 35 35 Figure 3 6 Horizontal Field of View...

Page 43: ...laserBIRD Installation and Operation Guide 36 36 36 36 Figure 3 7 Vertical Field of View...

Page 45: ......