28

12.4.2.3. CORRECTION OF PID PARAMETERS

The automatic tuning function correctly selects the PID regulation parameters for most processes; however,

sometimes it may be necessary to correct them. Due to the strong correlation between those parameters, only

one parameter should be changed in the selected

Set of PID parameters

and the impact of the change on the

process should be observed:

a) oscillations around the threshold - increase the

Proportional band Pb

or the

Integration time constant Ti

,

decrease the

Differentiation time constant Td

(or reduce by a half the

Pulsing period Tc for the output

)

b) slow response - decrease the

Proportional band Pb

, the

Differentiation time constant Td

, and the

Integration

time constant Ti

c) over-regulation - increase the

Proportional band Pb

, the

Differentiation time constant Td

, and the

Integration time constant Ti

d) instability - increase the

Integration time constant Ti

12.4.3. SETS OF PROGRAM CONTROL PARAMETERS

The controller makes it possible to create 4 independent control programs, each consisting of a maximum of 12

sections. The programs can be freely assigned to individual control outputs with the parameters

Setpoint (SP)

selection

set to

Setpoint value from Program 1

÷

4

(chapter 12.4.1). Also, it is possible to define auxiliary outputs

and sound alarms for individual sections of the program, which may be used for indicating the operation status

and for switching on additional devices (fans, additional heating sections, etc.) The option of power control (when

the

Auxiliary output state

parameter is set to

Manual mode with a set value

); a description is given in the table

12.4.3. The diagram with an example of a configuration of a program consisting of 4 sections is shown in chapter

12.4.3.1. The program is started at the time of start of the control (automatically or manually, chapter 12.4.1.1) and

is always performed from the start (the 1st section). In the

CONTROL

type window (chapter 11.2) and in the

Quick

configuration screen

, the status of operation of the program is shown in the line starting with the phrase PRGx

(where x is the number of the program; the meaning of the individual fields is the following:

PRGx: the number of

the current section/the number of all sections: the type of the stage

, e.g.

PRG1:4/5:60m

(program 1, section four out of

the five sections used, remaining time of the section 60 minutes). Depending on the

Stage type

parameter, the

stage type

field can have the values described in the table below (12.4.3).

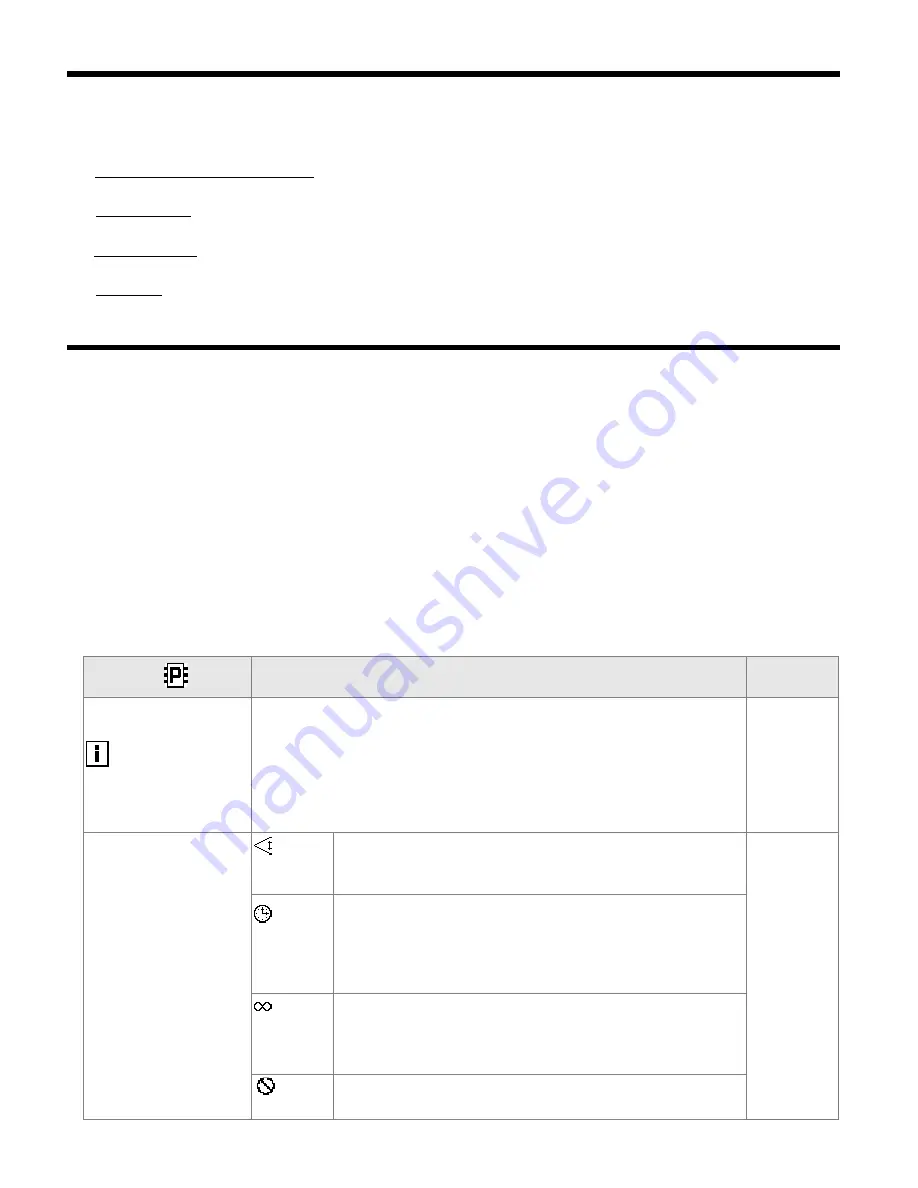

Table 12.4.3. The parameters in the

Control and alarms options

menu for the selected section (1

÷

12) of the program (1

÷

4)

Parameter

Range of variability of the parameter and description

Factory

settings

Assigned and active

outputs

the numbers (

1

÷

4

or

None

) are displayed of the control outputs to which the

presented program is related (using the parameters

Setpoint (SP) selection

)

and of the auxiliary outputs for the current section of the program (set with

the

Assignment of the control signal

parameter for the outputs and the

Selection of auxiliary output

parameter for the section); a description of the

parameters is given in chapter 12.4.1 and in this table; if the value is

None

, the

program is not used or the outputs are disabled.

None

Stage type

Gradient

(PV/min)

achievement of the

Set point value SP

with the set gradient

(ramping) defined by the parameter

Gradient (PV/min)

, the

stage

type

field in the operation status has the value of

PV/min

Gradient

(PV/min)

Stage

time after

reaching of

the SP

the time countdown starts after the measured value reaches the

band defined by the parameter

Hysteresis and band for the start

of the stage time

, the

stage type

field in the status shows

PV->SP

(achievement of the

Setpoint value SP

) or the remaining

Stage

time

(in minutes or seconds when time<1 min.)

Continuous

(without a

time limit)

the

stage type

field in the status always has the value

PV->SP

(achievement of the

Setpoint value SP

), at the same time this is

the last section of the program with constantly enabled control

End

(stop)

the last section of the program, control stopped, status field

stage

type

=

Stop