26

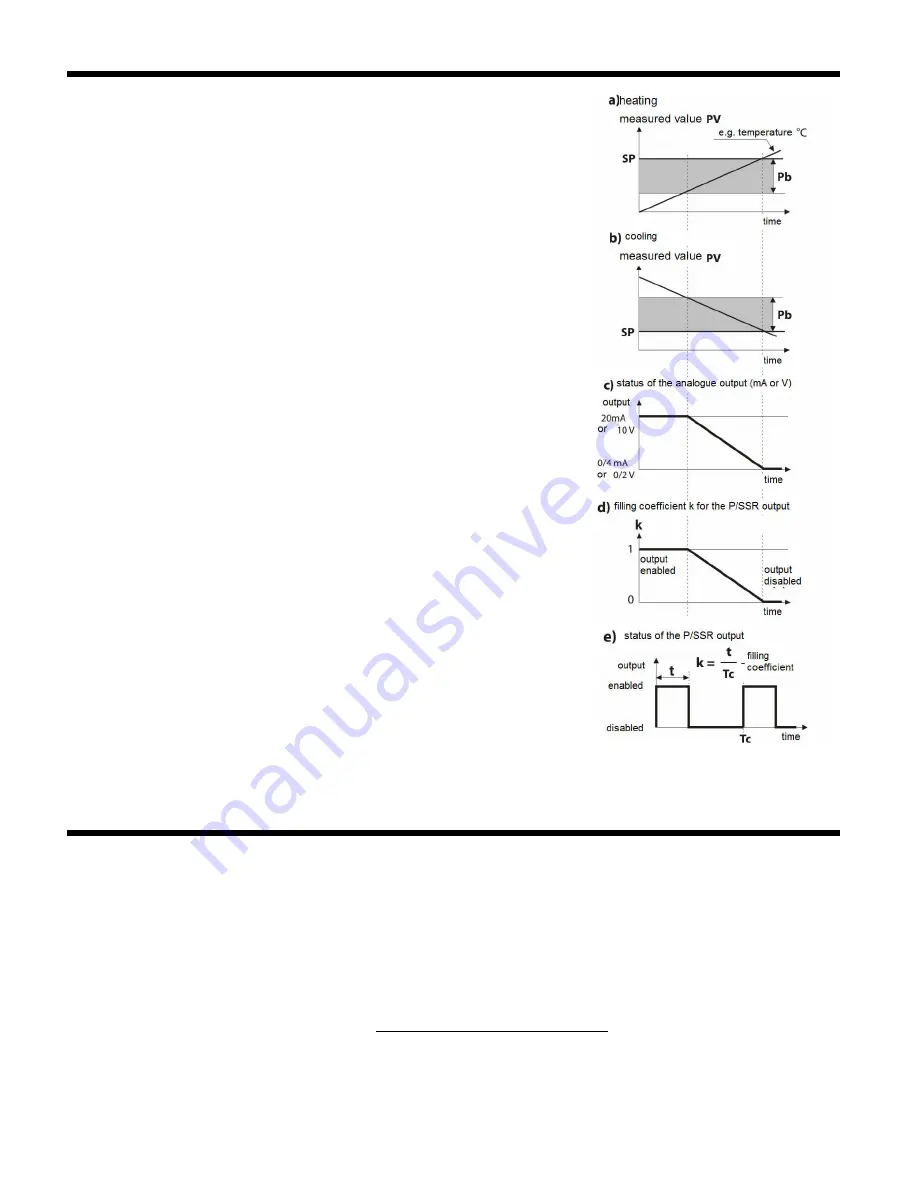

12.4.2.1. PID REGULATION

The PID algorithm enables achieving smaller control errors (e.g.

temperature) than the ON-OFF method with hysteresis. However, the

algorithm requires selecting the characteristic parameters for the specific

controlled object (e.g. a furnace). In order to simplify the operation, the

controller is provided with the advanced PID parameter selection functions

described in chapter 12.4.2.2. Also, it is always possible to manually correct

the settings (chapter 12.4.2.3).

PID type control is active when the

PID Selection for the SP...

parameter

(both for the setpoint values for the individual outputs, chapter 12.4.1, and

for sections of program control, chapter 12.4.2) indicates one of the

Sets of

PID parameters

(chapter 12.4.2). The location of the

Proportional band Pb

in relation to the setpoint value

SP

is shown in drawings 12.4.2.1 a) and b).

The impact of the integrating and differentiating component of the PID

control is set by the parameters

Integration time constant Ti

and

Differentiation time constant Td

. The parameter

Impulse parameter Tc

applies only to outputs of the P/SSR type. If the PID algorithm is

implemented by the 0/4÷20 mA or 0/2÷10 V analogue output, the

Pulsing

period Tc

parameter is insignificant. Then the output signal may assume

intermediate values from the entire range of variability of the output.

Regardless of the type of the output, the correction of its state always takes

place every 1 s.

The principle of P-type control (proportional control) for the P/SSR output is

shown in figures d) and e) and, that for the analogue output, in figure c).

Fig. 12.4.2.1. Principle of operation of PID control:

a) location of the range of proportionality

Pb

in relation to the setpoint

value

SP

for heating (parameter

Control type

=

Reverse/heating

)

b) location of the range of proportionality

Pb

in relation to the setpoint

value

SP

for cooling (

Control type

=

Direct/cooling

)

c) state of the 0/4÷20 mA or 0/2÷10 V analogue output

d) filling coefficient for the bistate output of the P/SSR type

e) state of the P/SSR output (for the measured value within the

proportionality range

Pb

)

12.4.2.2. AUTOTUNING OF PID PARAMETERS

In order to use the PID parameter selection function for a specific control output, it is firs necessary to select the

Set of PID parameters

(using the parameters

PID selection for SP1

or

SP2

, chapter 12.4.1) for which the calculated

data will be saved, and then to set the autotuning type (using the parameter

Autotuning of PID parameters

). The

autotuning starts at the time of start of the control (automatic or manual, chapter 12.4.1.1). Operation of

autotuning is independent for each of the outputs and is signalized with the message

ST-PID

in the status of the

control channel shown in the window of the

CONTROL

type (chapter 11.2) and in the

Quick configuration screen

(chapter 11.7).

The value of the

Autotuning of PID parameters

determines the selection of the method of selection of PID parameters:

a)

Automatic selection (continuous mode)

- the controller continuously checks if there are appropriate conditions

for starting the tuning and tests the object in order to select the proper method. The algorithm continuously

forces operation in the PID mode. The necessary condition for initiation of the PID parameters selection

procedure is the location of the current measured value

PV

(indicated by the parameter

Assignment of control

signal

) outside of the insensitivity zone defined as the sum of the values of the parameters

Proportional band