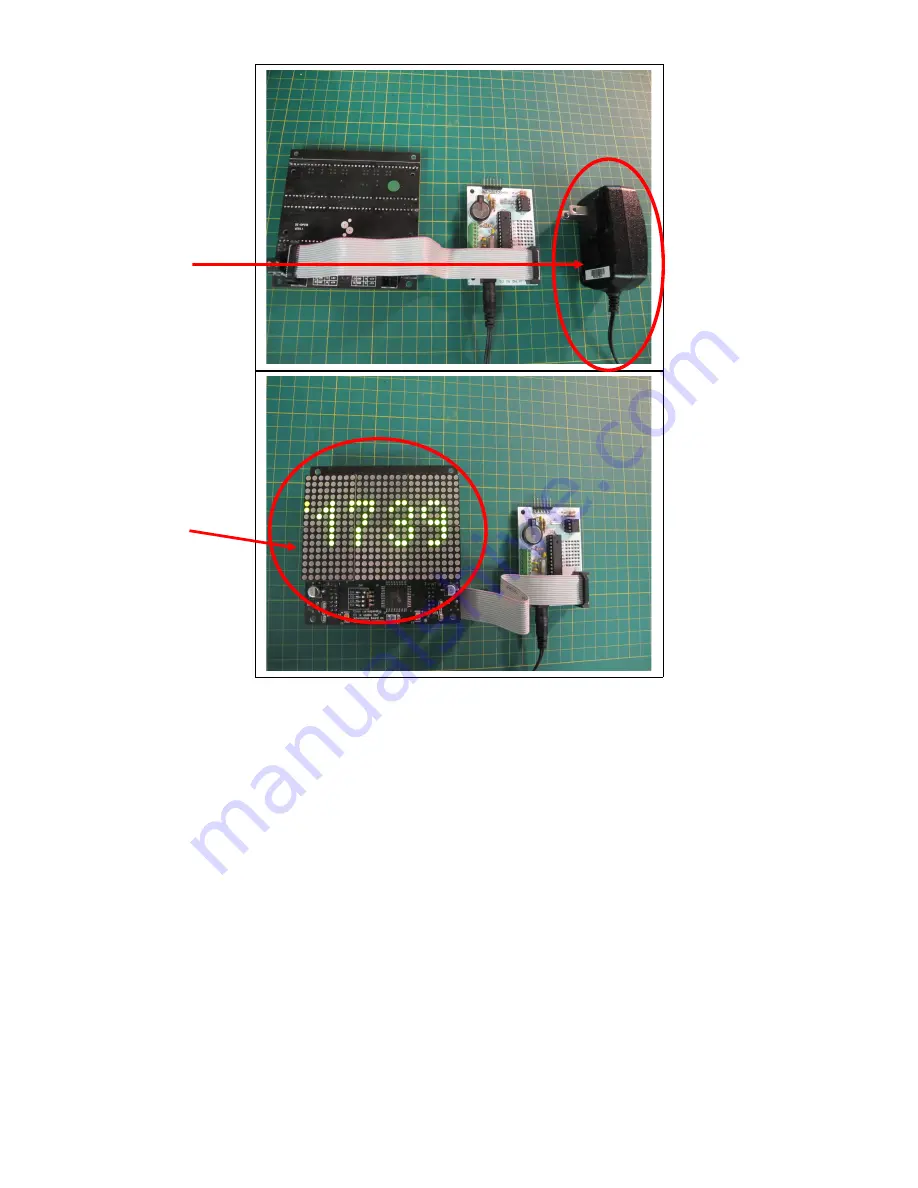

F)

Once you’ve ensured your screen works properly, you can unhook the power

supply and remove the ribbon cable from the PCB. You should then use the

white zip tie to bundle one loop of excess ribbon cable.

20

Plug the power

supply into the

board and plug the

supply into the wall

The display will

show a simple

time animation

with hours and

minutes