TM 9-2320-283-20-3

CAB AND BODY.

TEST EQUIPMENT

3 - 1 3 9 .

None.

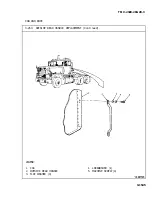

3-260. CENTER FLOOR PAN ACCESS COVER REPLACEMENT.

THIS TASK COVERS

a.

Removal.

b. Cleaning and Inspection.

c . I n s t a l l a t i o n .

INITIAL SETUP

EQUIPMENT CONDITION

APPLICABLE CONFIGURATIONS

PARAGRAPH

CONDITION DESCRIPTION

A l l .

3-137.

S h i f t e r c o n t r o l

removed.

S h i f t e r c o n t r o l m o u n t -

i n g b r a c k e t r e m o v e d .

SPECIAL TOOLS

None.

MATERIALS/PARTS (P/N)

None.

PERSONNEL REQUIRED

One (MOS-63S).

SPECIAL ENVIRONMENTAL CONDITIONS

None.

REFERENCES (TM)

GENERAL SAFETY INSTRUCTIONS

None.

E n g i n e o f f .

T r a n s m i s s i o n i n n e u t r a l .

P a r k b r a k e s e t .

TROUBLESHOOTING REFERENCES

None.

3-1532

Summary of Contents for M915A1

Page 10: ......

Page 17: ......

Page 59: ......

Page 130: ......

Page 155: ......

Page 378: ...TM 9 2320 283 20 3 CAB AND BODY 3 264 OUTSIDE FRONT HANDLE REPLACEMENT Continued 3 1551...

Page 622: ...TM 9 2320 283 20 3 GAGES NONELECTRICAL 3 309 TACHOGRAPH REPLACEMENT Continued TA 237846 3 1795...

Page 669: ......

Page 673: ......

Page 705: ......

Page 707: ......

Page 717: ......

Page 737: ......

Page 738: ......

Page 739: ......

Page 740: ......

Page 741: ......

Page 742: ......

Page 743: ......

Page 744: ......

Page 745: ......

Page 746: ......

Page 748: ......

Page 756: ...PIN 054576 000...