36

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

6.2.2

EVERY MONTH

• Check lift screws correct tightening;

• Check hydraulic system correct sealing; tighten loose unions, if necessary;

• Check hoses for wear; if worn out, change them with new equivalent ones;

• Check runways structure conditions; change any damaged part with original spare parts.

6.2.3

EVERY 200 OPERATING HOURS OR EVERY 5 YEARS, AT THE LATEST

Replace hydraulic system oil, discharging the exhausted oil from tank. Clean oil filter. For this operation, please

refer to "Hydraulic control unit" table in the attached spare parts section.

If these operations are carried out with the utmost care, the user will find the equipment in perfect working

conditions upon lift restart.

It has to be remembered that the Manufacturer and its distributors are always at your disposal for any service and spare part

needs.

7.

TROUBLESHOOTING

PROBLEMI / PROBLEMS

A

Il ponte non funziona. Nessuna reazione. /

The lift does not work. No reaction.

B Posizione P2 più bassa in relazione a P1. /

P2 position lower than P1.

C Premendo il pulsante di discesa, il ponte non scende, /

Push the down button, the lift stopped.

D Il sollevatore non mantiene l’allineamento. /

The lift does not stay aligned

POSSIBILI CAUSE / POSSIBLE CAUSES

INTERVENTI /

ACTIONS

A

-

Switch/Disconnector (11, Fig. 1) to OFF (0).

- No power supply.

- Cable connections.

- Burnt-out fuses.

-

- Reset Emergency Switch/Disconnector to ON (1).

- Check cause.

- Check connections.

Replace.

B

-

- Presence of air in the system.

- Inside blow-by through gaskets.

-

- Bleed and realign at maximum height.

Replace the gaskets.

C

- Safety micro-switch (FC1- Fig. 1)

tripped or faulty.

- Solenoid valve (EV1 +Ev2+Ev3 Fig. 16) faulty.

- Check the micro-switch.

Check the solenoid valve and replace, if required.

D -

- Oil blow-by inside the cylinder.

- Check oil level and bleed with lift at

maximum height.

- lift at maximum height.

- replace gaskets.

7.1

SPARE PARTS

Spare parts purchase orders shall be carried out by the manufacturer, and shall include the following information:

• Lift type, version, and serial number. These data are stamped on the plate fixed to all the equipment (18, Fig. 1).

• Spare parts table number, and part number.

• Part description and required quantity.

• Shipping means. If this item is not specified, the manufacturer, even devoting special care to this service, is notliable

for any shipping delay due to force majeure.

Shipping charges always have to be borne by the consignee. Goods travel at consignee's risk, even if sold free at

destination.

In case of request, please refer only to the code number of each single item..

Summary of Contents for PRATIK 30

Page 2: ...2 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 3: ...3 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 4: ...4 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

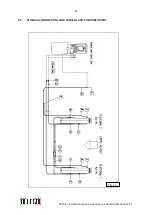

Page 37: ...37 PRATIK Installation use and maintenance ENG EDITION 2018 07 05 8 0 HYDRAULIC SCHEME...

Page 38: ...38 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 42: ...42 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 44: ...44 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

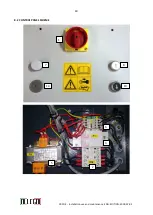

Page 53: ...53 PRATIK Installation use and maintenance ENG EDITION 2018 07 05 TAV 3 CONTROL UNIT...