35

PRATIK - Installation use and maintenance ENG- EDITION: 2018-07-05

6.

MAINTENANCE

Maintenance operations are listed hereinafter. A lower running cost and a longer machine

life depend,

among other things, on the constant execution of these operations.

CAUTION:

The listed time schedule is given for information, and relates to standard operating conditions.

It is susceptible of changes based on the type of service, level of environmental dusts, frequency

f usage, etc. In case of heavier conditions, maintenance operations shall be carried out more frequently.

When topping-up or changing oil, always use the same type of oil used before.

To clean the lift DO NOT use aggressive products, in case of accidental spills of corrosive liquids

immediately dry the surfaces concerned.

6.1 SAFETY DEVICES CHECK

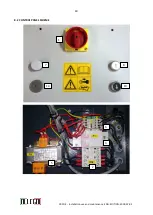

6.1.1 EMERGENCY DISCONNECTOR/OFF

1 Turn Emergency Switch/Disconnector (10, Fig. 1A) to 1 (ON).

2 Carry out any operation required for LOWERING or RAISING.

3 Meanwhile, turn Emergency Switch/Disconnector (10, Fig. 1A) to 0 (OFF): lift will completely stop working;

runways shall stop.

6.1.2 VOLTAGE WARNING LIGHT

1 Check that the Switch/Disconnector (10, Fig. 1A) is set to OFF (0), turn it, if necessary.

2 Turn Emergency Switch/Disconnector to ON (1).

3 Check that the voltage warning light (13, Fig. 1A) is on..

6.1.3 AUTOMATIC ALIGNMENT AND AIR BLEEDING

1 Move lift up to the max. height.

2 Hold up push-button for 5-10 seconds.

3 Lower the lift.

This operation is also possible with lift under load, if the difference in height of the two runways ranges

between

4-5 centimetres

6.1.4 RUBBER PADS

Check their conditions. If worn-out or broken, change them.

6.2 PERIODICAL MAINTENANCE

6.2.1 EVERY WEEK

• Check safety devices every week, as specified in this manual.

• Check hydraulic oil level as follows:

• Move runways all the way down;

• Turn Emergency Switch/Disconnector (10, Fig. 1A) to 0 (OFF);

• Check hydraulic oil level that shall be 2 cm below the oil filling plug. If necessary, top up with hydraulic oil

"ESSO NUTO H32" or equivalent;

• Grease linkages (1, Fig.16A), by means of grease nipple (2, Fig.16A).

CAUTION: Routine maintenance: performed only by authorized operator

Extraordinary maintenance: performed only by authorized and trained operator

Summary of Contents for PRATIK 30

Page 2: ...2 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 3: ...3 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 4: ...4 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

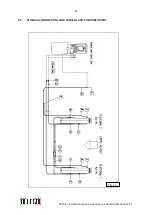

Page 37: ...37 PRATIK Installation use and maintenance ENG EDITION 2018 07 05 8 0 HYDRAULIC SCHEME...

Page 38: ...38 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 42: ...42 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 44: ...44 PRATIK Installation use and maintenance ENG EDITION 2018 07 05...

Page 53: ...53 PRATIK Installation use and maintenance ENG EDITION 2018 07 05 TAV 3 CONTROL UNIT...