User manual MKA 120

Conforms to

Issue 07.07.2021_01 Page 5

2

Introduction

2.1 Overview

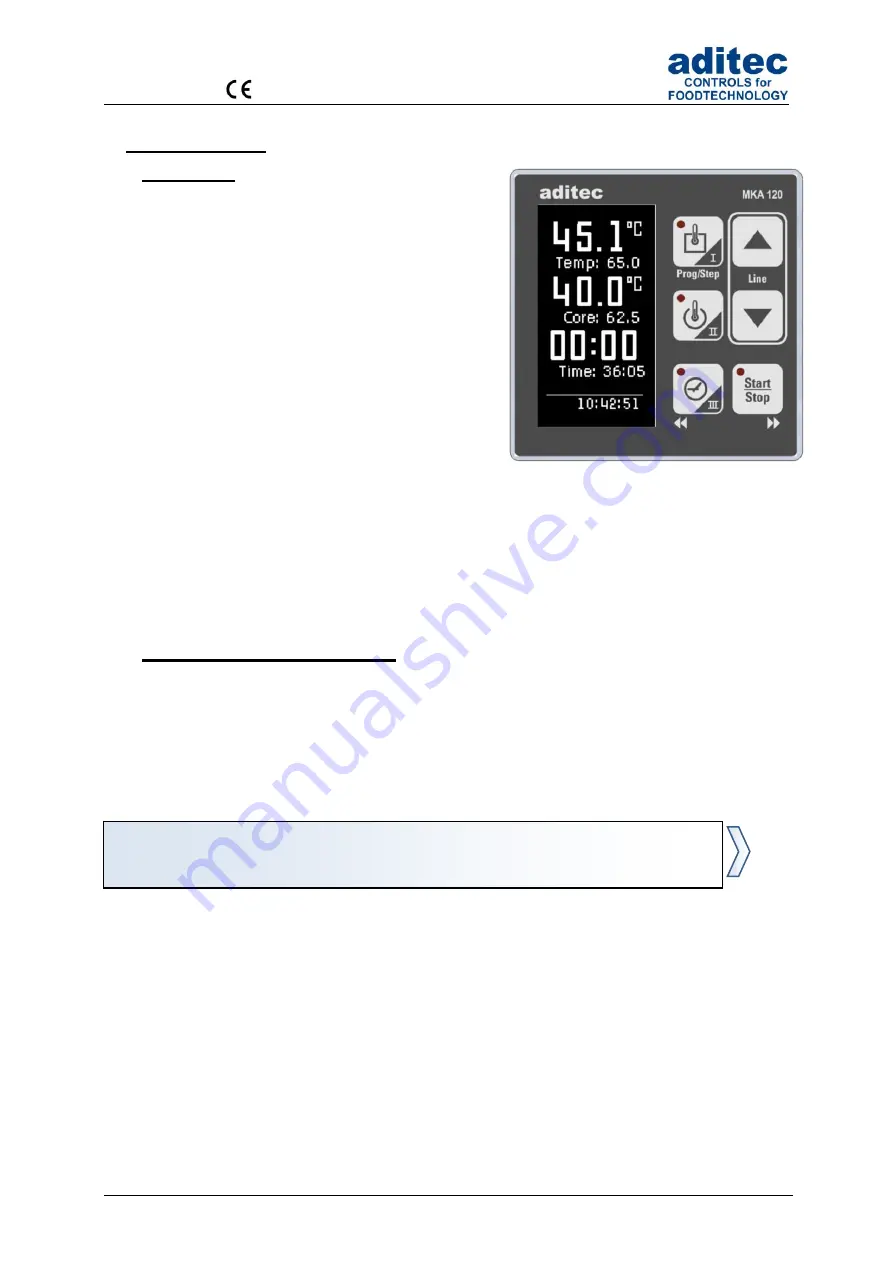

Controller

MKA 120

has been developed

for use in

cooking, baking and boiler systems

. It is infinitely

variable and can be easily adapted for a range of

applications.

The controller has 2 temperature measurement inputs

and 3 potential-free output relays. The controller

regulates the temperature through heating or cooling.

Shut-down conditions can be either the operating time

and/or the core temperature. Delta T cooking is also

possible with the appropriate encoding.

The assignment of relays to the processes is infinitely

variable. Relays can be assigned as leading, lagging,

switch-on as well as switch-off delayed or pulsing relays.

An optional serial interface allows for data transfers

between the controller MKA120 and a PC. The controller

can be programmed via a PC with the installed

aditec service program

. The connection is made via

a mini USB or optionally via LAN or a serial interface RS485, respectively.

The visualisation program

aditec „VisuNet“

allows you to connect one or several controllers to a

superordinate program surveillance. This enables you to log temperature profiles, treatment types etc.

and ensures comprehensive quality control of the treated products in compliance with HACCP and IFS

(ISO 9000). Furthermore the tele-control and remote maintenance system

aditec Control

lets you

monitor and operate the VisuNet program from anywhere, thereby allowing you to directly influence

the system.

2.2 Controller characteristics

⚫

Number of programs and steps can be pre-programmed, max.99 steps in total, 1 manual program.

⚫

Straight forward, systematic setting of the configuration data.

⚫

Programmabel processes

⚫

3 potential-free relay outputs can be programmed

⚫

2 x galvanically isolated analogue inputs which can be programmed as: Pt100 (for 3 wire connection

with automatic power compensation), all standardised thermo-elements incomplince with DIN EN

60584 among others Type K: NiCr-Ni. Pt100 or as digital inputs

⚫

Ethernet LAN for connection to a PC or connection via an expansion card (ZSL)

⚫

RS485 for connection to a PC via an expansion card (ZS4)

⚫

Mini USB connection (USB serial port for a firmware update)

⚫

4 x LED buttons (red) for status displays

⚫

OLED-display with 128x64 pixel resolution and 16 grey scales

⚫

Robust stainless steel housing (1.4016)

⚫

Network for the visualisation and recording in accordance with HACCP is possible with

aditec-

VisuNet

⚫

Programmable nominal limit values

⚫

Program memory is retained during a power cut

⚫

Programs interrupted by a power cut will be resumed at the point (can be defined) where they were

interrupted once power is restored.

⚫

Process runtime from 00h : 01min to 99h : 59min or continuous operation

⚫

Pre-set time (start time) can be pre-set via real time/date

⚫

Sensor breaks (interruption or short circuit) are shown

⚫

5 limit value alarms

Optional

choises