19

1.11.

Boiler lockout

When operating anomalies occur, the boiler automatically shuts down. Refer to Table 3 and Table 4 to recognize the boiler operating

status.To recognize the possible causes of the malfunction, see also paragraph “7. Technical problems table ”at the end of this booklet.

Depending on the type of block found, proceed as described below.

1.11.1.

Burner lockout

In the event of burner lockout due to no flame, the E06 code flashes on the display. In this case, proceed as follows:

- check that the gas cock is open and that there is gas in the network, for example by lighting a stove;

- having checked the presence of fuel, unblock the burner by pressing the " " button (B fig. 1): if the appliance does not restart and

returns to lockout, on the third attempt contact an Authorized Service Center or qualified personnel for maintenance .

If the burner shuts down frequently, a sign of a recurring malfunction in operation, contact an Authorized Service Center or qualified

personnel for maintenance.

1.11.2.

Overtemperature lockout

In case of overheating of the supply water, the boiler is blocked and the code

E07

flashes. In this case, contact an Authorized Service

Center or qualified personnel for maintenance.

1.11.3.

Block due to lack of draft (smoke block)

In the event of a malfunction of the air intake and / or flue gas exhaust systems, the boiler is blocked, the display shows the flashing code

E13

0

E96

(intervention of the fumes probe).In this case, contact an Authorized Service Center or qualified personnel for maintenance.

1.11.4.

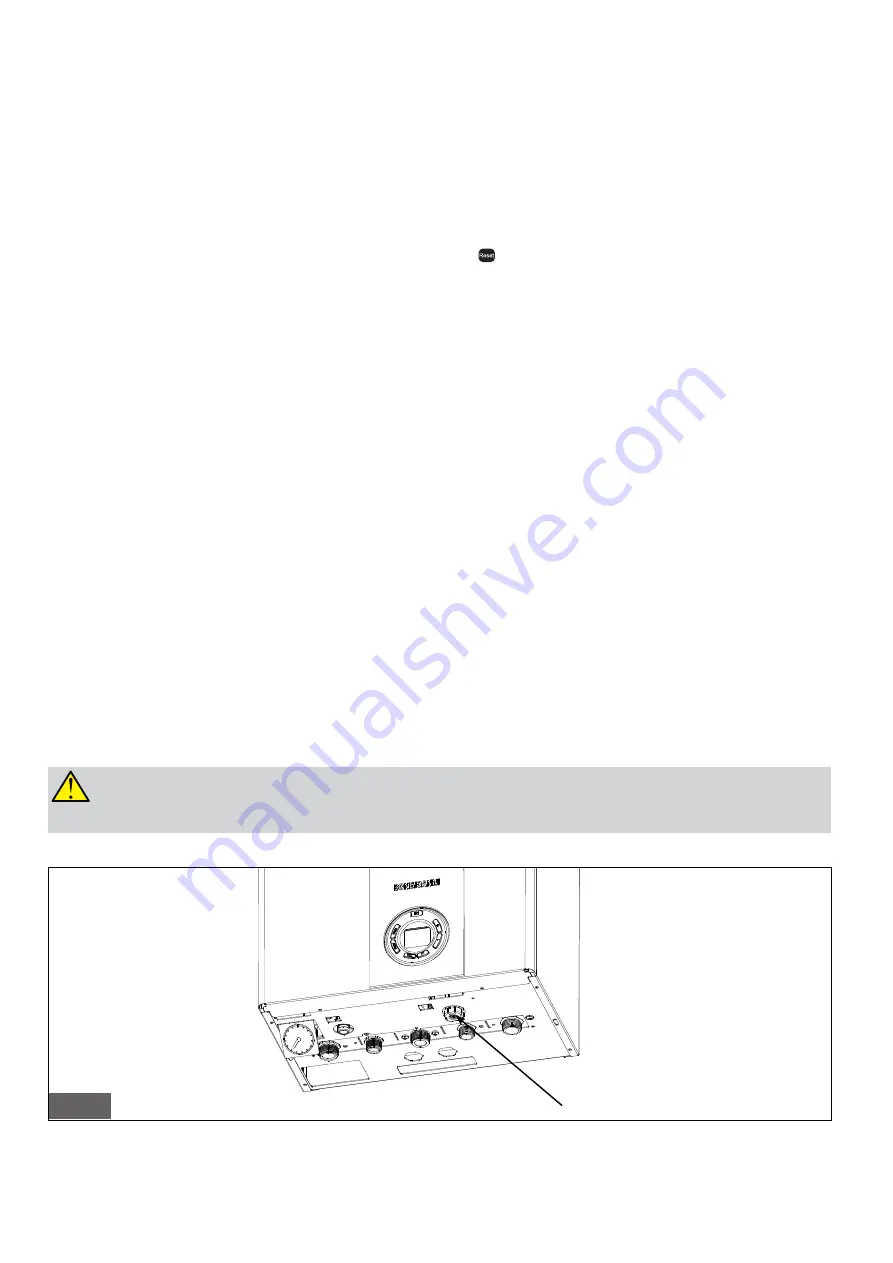

Block due to insufficient water pressure in the system

If the

E02

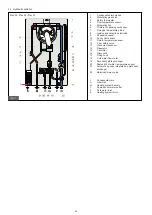

blocking error due to insufficient system pressure flashes, fill the system by acting on the filling tap in fig. 2 (for SV models the

tap is located on the cold water inlet pipe).

Error

E02

is displayed when the system pressure falls below the value of 0.5 bar and resets automatically when the system pressure

exceeds the threshold of 1.1 bar.

The pressure value with the boiler cold must be 1 ÷ 1.3 bar.

To restore the water pressure value, proceed as follows:

- pull the knob down to remove it;

- turn the filler tap knob (fig. 2) anticlockwise to allow the water to enter the boiler;

- keep the tap open until a pressure value of 1 ÷ 1.3 bar is reached on the control panel;

- close the tap by turning the knob clockwise;

- push the knob upwards to make it retract.

If the boiler locks up again, contact an Authorized Service Center or qualified personnel for maintenance.

At the end of the operation, close the filling tap well. If the tap is not closed properly, due to an increase in

pressure above 2.6 bar, the presence of error E03 on the display and subsequently the opening of the

safety valve of the heating system and the leakage of hot water could occur. -here.

Rubinetto di carico

fig. 2