www.a2asimulations.com

ACCU-SIM V35B BONANZA

:::

A2A

SIMULATIONS

109

FOR SIMULATION USE ONLY

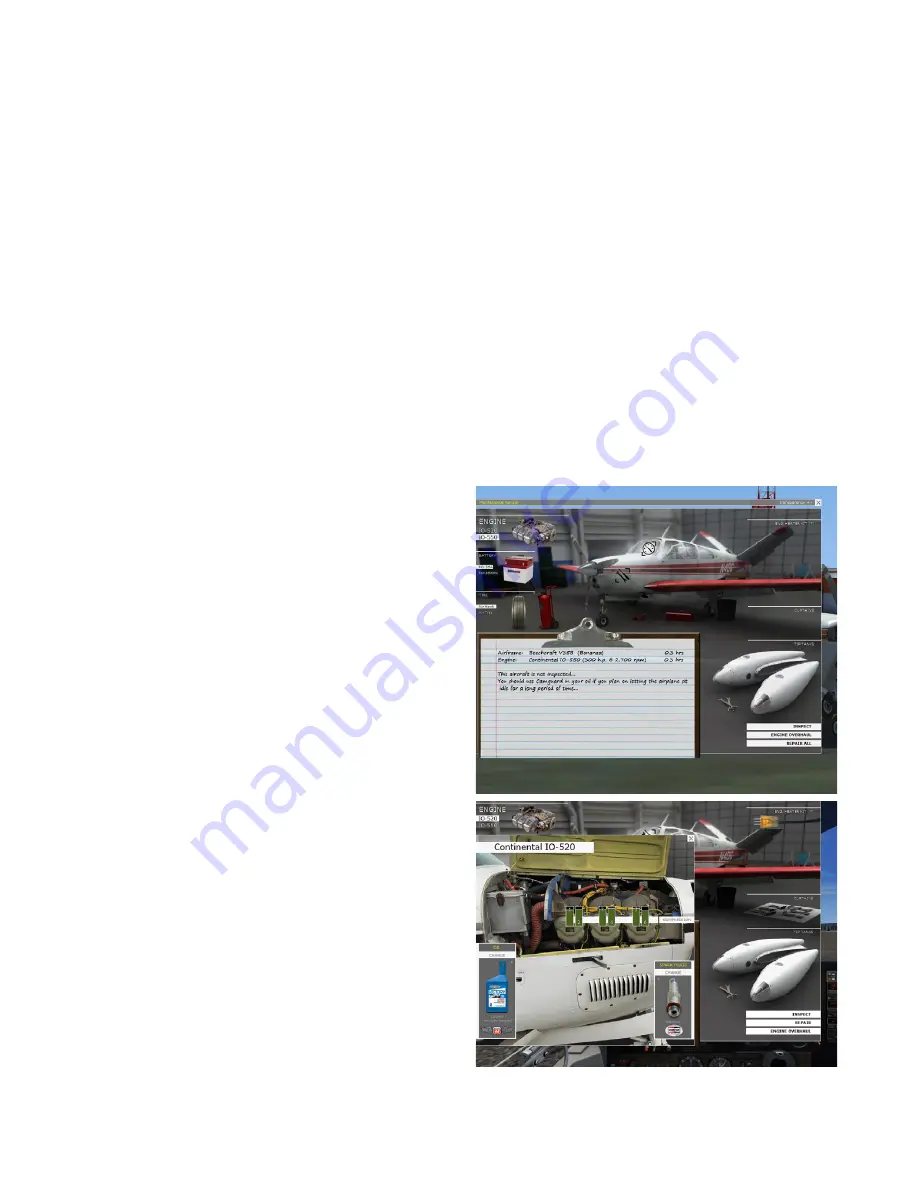

Maintenance Hangar (Shift 7)

The maintenance hangar is where you can review the cur-

rent state of your aircraft and its major systems. It is one of

the core elements to visualizing Accusim at work.

With the invaluable assistance of your local aircraft mainte-

nance engineer/technician, a.k.a. “grease monkey”, you will

be able to see a full and in-depth report stating the following:

• A summary of your airframe, engine

and propeller installed.

• Total airframe hours, and engine hours

since the last major overhaul.

• General condition of the engine.

• Important notes provided by the ground crew.

From the maintenance hangar, you can also carry out a

complete overhaul, by clicking the COMPLETE OVERHAUL

button in the bottom right corner. This will overhaul the

engine and replace any parts that are showing signs of

wear or damage, with new or re-conditioned parts.

In order to fix any issues the mechanic has flagged up, we

need to inspect the engine in greater detail. By left clicking

the “CHECK ENGINE” text on the engine cover, it will open

the following window.

COLOR CODES:

• GREEN: OK

• YELLOW: WATCH

• RED: MUST FIX OR REPLACE

Heavy wear or a component failure will be shown in red,

and these components must be replaced.

We can choose to continue flying with the worn compo-

nents, but extra care should be used and a close eye kept on

those systems/components.

Any component with a yellow highlight is worn, but not

unserviceable, so do not have to be replaced.

Compression Test

At the lower right hand corner is a “COMPRESSION TEST”

button, which will tell your mechanic to run a high pressure

differential compression test on the engine cylinders.

This is done by compressed air being applied through

a regulator gauge to the tester in the cylinder. The gauge

would show the total pressure being applied to the cylinder.

The compressed air would then pass through a calibrated

restrictor and to the cylinder pressure gauge. This gauge would

show the actual air pressure within the cylinder.

Any difference in pressure between the two gauges would

indicate a leak of air past the engine components, whether

that is the valves, piston rings, or even a crack in the cyl-

inder wall itself.

The readings that your mechanic presents to you in the

“Compression Test Results” in the notes section, will be

annotated with the actual amount of pressure read in the cyl-

inder over the actual pressure that was applied to the cylinder

through the regulator.

Low compression on a cylinder isn’t nec essarily a ter-

rible thing, because as the en gine picks up in speed, the

worn cylinder becomes productive. It is mostly noticed at

lower RPM’s where the cylinder may have trouble firing,

and also a marked increase in oil consumption may also

occur (sometimes with an accompanying blue smoke out of

that cylinder during flight).

However, note that this is a reading of the general condi-

tion of the cylinders, and lower condition does bring addi-

tional risks of failure, or even engine fires.

Summary of Contents for BONANZA ACCU-SIM V35B

Page 1: ...A2ASIMULATIONS BONANZA ACCU SIM V35B BONANZA ...

Page 3: ...A2ASIMULATIONS BONANZA ACCU SIM V35B BONANZA ...

Page 5: ...www a2asimulations com ACCU SIM V35B BONANZA A2ASIMULATIONS 5 FOR SIMULATION USE ONLY ...

Page 27: ...www a2asimulations com ACCU SIM V35B BONANZA A2ASIMULATIONS 27 FOR SIMULATION USE ONLY ...

Page 58: ......

Page 68: ...68 A2ASIMULATIONS ACCU SIM V35B BONANZA www a2asimulations com FOR SIMULATION USE ONLY ...

Page 112: ......