Working principle of the water heater

18

Instruction manual SGS

2

gis

2.5.1

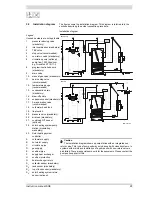

Unvented installation

With an unvented installation, an expansion valve and expansion vessel prevent

the buildup of excessive pressure in the tank. This prevents damage being

caused to the enamel coating (in the water heater) or to the tank. A non-return

valve prevents excessive pressure build-up in the water supply system. This

valve also prevents water from flowing backwards from the tank into the cold

water supply system. The pressure-reducing valve protects the water heater

against excess mains water pressure (3.4.2 "General and electrical

specifications"). These components are installed in the cold water

inlet (3.7 "Vented water connections").

2.5.2

Vented installation

With a vented installation, excess pressure is taken up by the open cold water

head tank. The level of the cold water head tank determines the maximum

working pressure (3.4.2 "General and electrical specifications") in the tank. The

water heater must also be fitted with a vent pipe from the hot water pipe, which

opens into the cold water head tank.

Ideally, the vent pipe should discharge into a separate discharge channel/drain

or otherwise to the open cold water head tank. The water heater should also be

fitted with a stop valve (3.6.2 "Hot water side") on the hot water side.

2.5.3

T&P valve

A T&P (Temperature and Pressure Relief) valve monitors the pressure in the

tank and the water temperature at the top of the tank. If the pressure in the tank

becomes too high or the water temperature becomes too hot, the valve will

open. The hot water can now flow out of the tank. Because the water heater and

storage tank are under water supply pressure, cold water will automatically flow

into the tank. The valve remains open until the unsafe situation has been

rectified. The water heater and storage tank are fitted standard with a

connection for a T&P valve (3.6.2 "Hot water side").

2.6

Protection for the

solar heating system

2.6.1

Drain-back tank

The solar heating system may optionally be equipped with a drain-back tank.

The tank fills itself with the heating fluid when there is no heat demand. This

avoids overheating of the solar heating system. The high insulation factor of the

tank also protects the system against freezing of the fluid. The use of the drain-

back tank also serves to extend the useful life of the fluid.

The existence of a drain-back tank is set (12.9.1 "Setting the drain-back tank")

during the installation. Refer to the solar heating system manual for more

details.

2.6.2

Fluid temperature

The heat exchanger of the solar heating system is filled with glycol. If the

temperature of the heating fluid is too high, a signal is sent to the controller of

the solar collector and the pump of the solar collector is switched off. This signal

is passed to the controller by temperature sensor S

1

.

Temperature protection for solar heating system

Protection

Description

Maximum temperature:

- S

1

> 130°C

The pump of the solar heating system switches off

when the temperature of the heating fluid at S

1

exceeds the maximum value. The solar heating

system enters error mode. The error is also visible

on the display of the SGS water heater

Summary of Contents for SGS - 100

Page 7: ...4 Instruction manual SGS gis...

Page 11: ...Contents 8 Instruction manual SGS...

Page 23: ...Working principle of the water heater 20 Instruction manual SGS 2 gis...

Page 37: ...Installation types 34 Instruction manual SGS Installation 3...

Page 57: ...Conversion to a different gas category 54 Instruction manual SGS 4 is...

Page 65: ...Draining 62 Instruction manual SGS 6 gis...

Page 71: ...Status of the water heater 68 Instruction manual SGS 8 gis...

Page 75: ...Shutting down 72 Instruction manual SGS 10 gis...

Page 103: ...Service interval 100 Instruction manual SGS 14 is...

Page 112: ...Instruction manual SGS 109 is...

Page 119: ...Instruction manual SGS 116...