INSTRUCTION MANUAL

Semi-automatic BOV Filling Machine Z-2323

A0310.02.2323.905.1.EN

Page 32/39

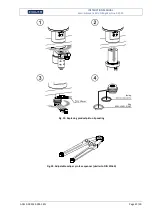

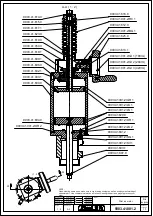

Replacing the lip seal in the filling head

The lip sealing mounted in filling head is a dynamic seal, therefore it is exposed to wear. Its condition

should be checked whenever symptoms of head leakage are occurring. In order to replace the

sealing perform following operations:

1.

Close the inlet of the product to the cylinder by tightening the knurled screw [Fig. 9, pos. 1]

of the product cylinder non-return valve after loosening the securing nut [Fig. 9, pos. 2].

2.

Disable product supply to the machine. It involves switching off any installed product

pumps and emptying whole installation supplying product to the machine.

3.

Place empty aerosol container with crimped valve under the filling head. Using footswitch

START perform single filling cycle on empty container.

4.

Disable compressed air supply. It involves closing the main cut-off valve and emptying

whole pneumatic installation supplying the machine.

5.

Block the filling head connector using 22 mm flat wrench and unscrew the filling head using

17 mm flat wrench (insert wrench between spring coils) - Fig. 22, pos. 1.

6.

Pull gently up and remove the spring, spring mounting washer and covering sleeve - Fig. 22,

pos. 2.

7.

Hold the filling head body with a 17 mm flat wrench and unscrew filling head terminal [Fig.

22, pos. 3] using the bigger end of service key [Fig. 21].

8.

Remove the adapter and the brass sleeve – [Fig. 22, pos. 4].

9.

Using the smaller end of service key unscrew the lip seal fitting nut – [Fig. 22, pos. 5].

10.

Replace the lip seal 9003.34.000.2 – [Fig. 22, pos. 6]. Before placing the seal, lubricate it

with pneumatic oil.

11.

Assemble the filling head parts in the opposite order.

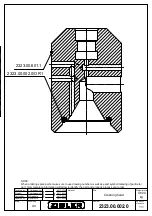

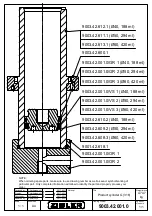

Fig. 21. Service key for filling head (part number 9003.46.001.2)

Содержание Z-2323

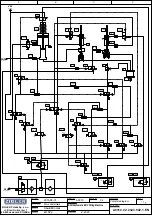

Страница 42: ...PNEUMATIC DIAGRAMS ...

Страница 44: ...SPARE PARTS LIST WITH TECHNICAL DRAWINGS ...