INSTRUCTION MANUAL

Semi-automatic BOV Filling Machine Z-2323

A0310.02.2323.905.1.EN

Page 27/39

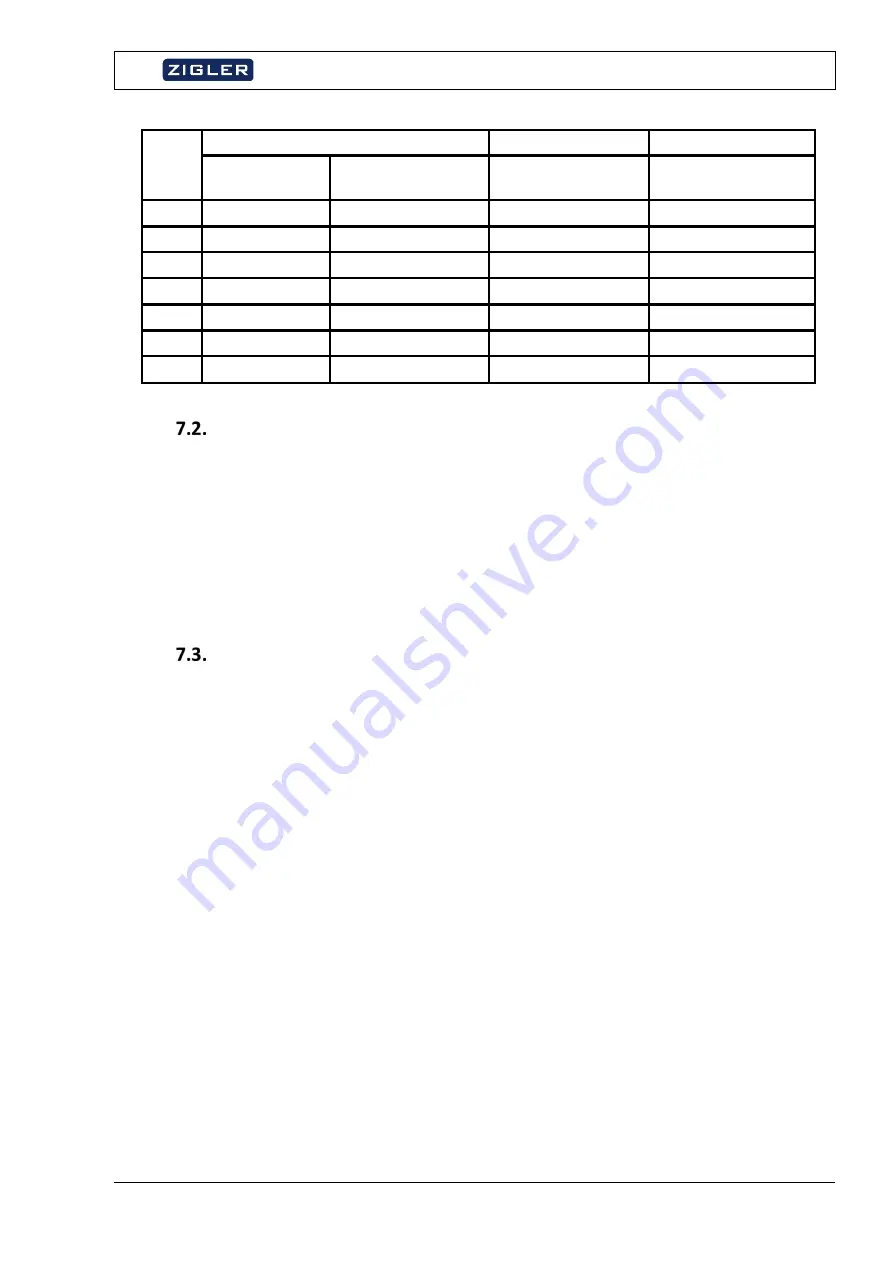

Tab. 3. Division into the quality classes according to the ISO 8573-1 norm

Class

1. SOLID PARTICLES

2. WATER CONTENT

3. OIL CONTENT

maximum

particle size (

µ

m)

maximum particle

viscosity (mg/m

3

)

maximum pressure

saturation point (

0

C)

maximum

concentration (mg/m

3

)

1

0,1

0,1

-70

0,01

2

1

1

-40

0,1

3

5

5

-20

1

4

15

8

+3

5

5

40

10

+7

25

6

-

-

+10

-

7

-

-

not defined

-

General rules applicable for replacing worn out parts

Mark air ducts before replacing,

It is forbidden to use pliers or pipe tongs. A piston axis, cylinder etc. damaged in the course

of dismantling causes a serious defect of the machine,

Wash every part thoroughly in kerosene or proper solvent.

Self-sealing rings and seals should never be mounted dry. Before fitting, they must always

be moistened with pneumatic oil.

Maintenance operations schedule

1.

Air preparation unit: check the quality of oil and fill it up, check the amount of oil dosed

into pneumatic systems – once a week.

2.

Water level in the air filter – check every day (do not allow the water to remain in the filter

tank).

3.

Lubrication control the of dose regulation gear mechanism (remove the protecting rubber

and provide the lubricate through the lubricating nipple) – once a year.

4.

Teflon cones in the Filling heads – check (and replace if necessary) once a month or more

frequently if they show the signs of wear and tear.

5.

Clean and lubricate the angular gear in the support stand – every half a year.

6.

Check condition of flat seal in Filling head (and replace if necessary) – everyday.

Содержание Z-2323

Страница 42: ...PNEUMATIC DIAGRAMS ...

Страница 44: ...SPARE PARTS LIST WITH TECHNICAL DRAWINGS ...