INSTRUCTION MANUAL

Semi-automatic BOV Filling Machine Z-2323

A0310.02.2323.905.1.EN

Page 28/39

Cleaning instructions

The machine should be cleaned after each production cycle which is a condition for proper and safe

operation of all machine components.

Z-2323 is made of steel and other materials resistant to the effects of most common detergents.

The machine should be cleaned manually using soft fabric or paper with cleaning and disinfecting

products.

Pneumatic oil feeder maintenance

The oil feeder of compressed air ensures the automatic lubrication of the pneumatic elements of

the machine. The settings should be periodically controlled and, in case of necessity, corrected. In

order to do so:

Switch cut-off valve to the open position

using the screwdriver, turn the adjustment screw:

a)

left, counter-clockwise - to increase the dose

b)

right, clockwise - to reduce the dose

Settings can be checked through a transparent eyehole in the dome with the adjustment

screw

In order to ensure proper working conditions the lubrication setting should

be at 1 DROP/500 WORK CYCLES!

After having been used for a while, water-oil emulsion is precipitated in the oil-feeder. In this case,

replace the oil by performing the following actions:

turn off the compressed air supply,

unscrew, empty and clean the oil-feeder tank,

fill the tank with fresh oil up to

3

/

4

of its height

screw the oil tank tight, paying attention to the suitable location of the seal.

Regularly once a month check the oil level, fill it up and in case of need remove polluted oil and

regulate the amount of the supplied oil.

Содержание Z-2323

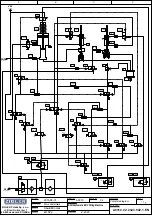

Страница 42: ...PNEUMATIC DIAGRAMS ...

Страница 44: ...SPARE PARTS LIST WITH TECHNICAL DRAWINGS ...