Page 26

TO GET ASSISTANCE, CALL: 919-774-7667

ZENITH PUMPS

Use 0-10 (VDC) as Setpoint

1. Preliminary Action:

•

External device which supplies 0-10 (VDC) speed set-

point signal to ZeDrive

•

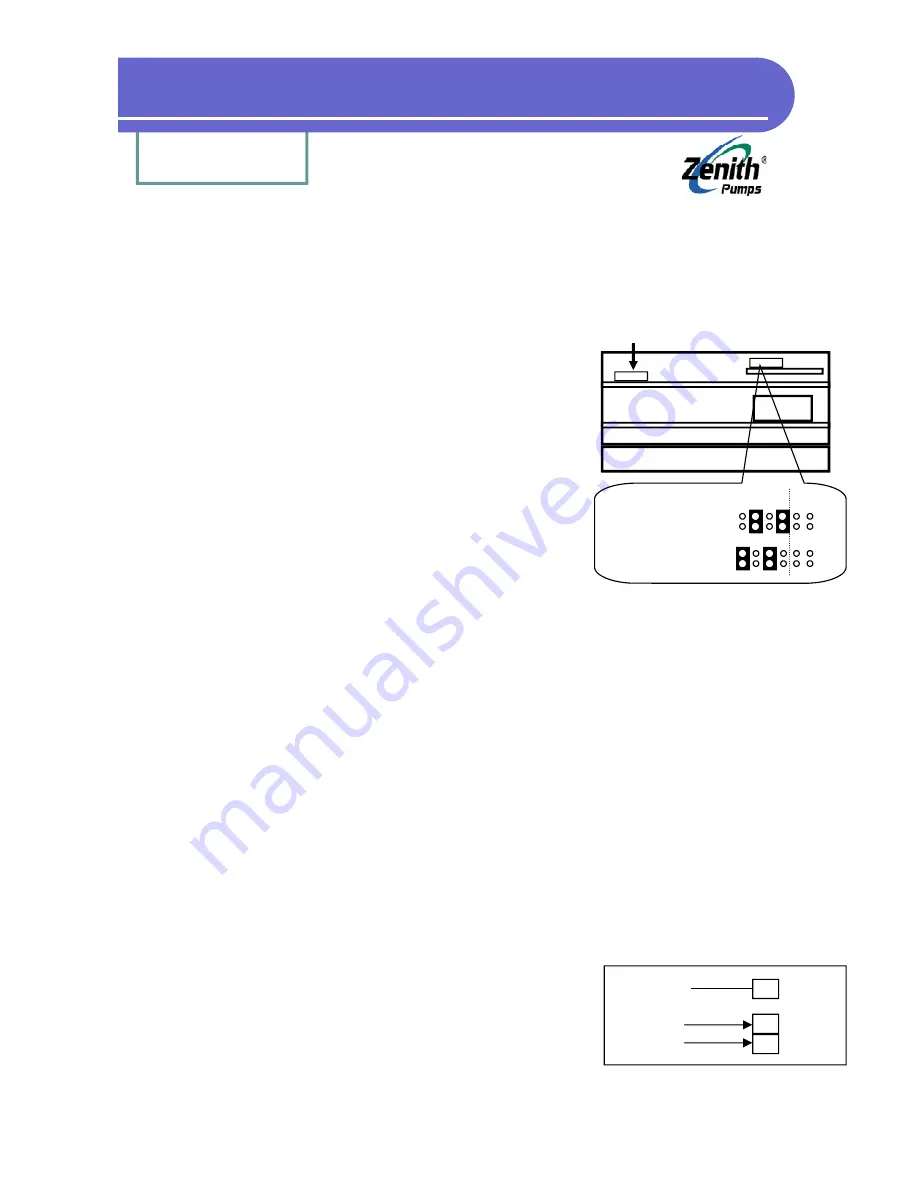

Locate Analog Select Jumpers on “Control Board”:

1. Loosen up 6 screws on the back panel, and 2

screws located on the heat sink of ZeDrive

2. Remove the back panel, place ZeDrive as shown

at left. The top board is the “Control Board”, and

the bottom one is “Drive Board”

3. Locate Analog Select Jumper as shown at left

4. Depend on the signal, change the jumper set-

ting as shown at the left

•

Pump Capacity — C

P

(cc/rev)

•

Reducer Gear Ratio — R. If the pump is directly coupled with the motor, the gear ratio R=1

•

Motor maximum speed — V

M

(RPM), 1800 (RPM) for most of systems supplied by Zenith

•

No. of Teeth of Feedback Gear — N, 120 for most of systems supplied by Zenith

2. Calculation:

•

To set the motor speed to be V (RPM) ( 0

≤

V

≤

V

M

), the pump to be V (RPM) ( 0/R

≤

V

≤

V

M

/R

), or the output to be V (cc/min) ( 0/R×C

P

≤

V

≤

V

M

/R×C

P

), the corresponding for-

mula for the control voltage C

VDC

is:

C

VDC

= (10 - 0) / (V

M

- 0) × V (VDC)

C

VDC

= (10 - 0)/ (V

M

/R - 0/R ) × V (VDC)

C

VDC

= (10 - 0)/ (V

M

/R×C

P

- 0/R×C

P

) × V (VDC)

3. Coding:

Check and change the following codes

Code 20 = Max. Setpoint in Engineering Unit (refer to sections “Set and Display as …”)

Code 22 = Max. Display in Engineering Unit (refer to sections “Set and Display as …”)

Code 31 = N

Code 34 = V

M

Code 61 = 1

Code 63 = 1

Code 84 = 4

4. Wiring:

•

Connect the wires of the 0-10 (VDC) speed control signal

with the ZeDrive as shown at the left

5. Result:

•

0-10 (VDC) signal can be used to control the speed of ZeDrive

Analog Select Jumper

Analog Select Jumper Location

Heat Sink

Transformer

Feedback

(Not this jumper)

4-20 mA:

Left

0-10 VDC:

(Default)

disregard

16

17

J4

10

J3

Shield

Signal

Common

From Device

Содержание ZeDrive

Страница 10: ...Page 9 TO GET ASSISTANCE CALL 919 774 7667 ZENITH PUMPS Control Cabinet Wiring...

Страница 18: ...Page 17 TO GET ASSISTANCE CALL 919 774 7667 ZENITH PUMPS Typical Applications Solutions...

Страница 38: ...Page 37 TO GET ASSISTANCE CALL 919 774 7667 ZENITH PUMPS Trouble shooting Fault Information...

Страница 45: ...Page 44 TO GET ASSISTANCE CALL 919 774 7667 ZENITH PUMPS Complete Code List...

Страница 59: ...Page 58 TO GET ASSISTANCE CALL 919 774 7667 ZENITH PUMPS System Drawings...