92

YORK INTERNATIONAL

(STOP LIMIT - START LIMIT)

T

ELAPSED

+ START LIMIT = % LOAD LIMIT

T

INTERVAL

LOAD LIMIT

100%

90%

80%

70%

60%

50%

40%

30%

20%

0 10 20 30 40 50 60 70 80 255

TIME (minutes)

(100 - 40) 20

+ 40 = 60

60

provides a purge pump service reminder. When the cu-

mulative purge pump operating hours since last service

equals the programmed service interval,

WARNING – PURGE PUMP SERVICE RECOMMENDED

is dis-

played on the keypad display. The service interval is pro-

grammable from 5-100 hours. The default value is 10

hours. Pressing the SETPOINT key displays the pro-

grammed service interval and accumulated pump oper-

ating hours since last service. After servicing the pump,

pressing the WARNING RESET key in SERVICE MODE

clears the warning message and resets the cumulative

operating hours to zero. Moving Micro Board program

jumper J57 from “CLKOFF” to “CLKON” position, as

would be done during unit commissioning, also resets

the cumulative operating hours to zero.

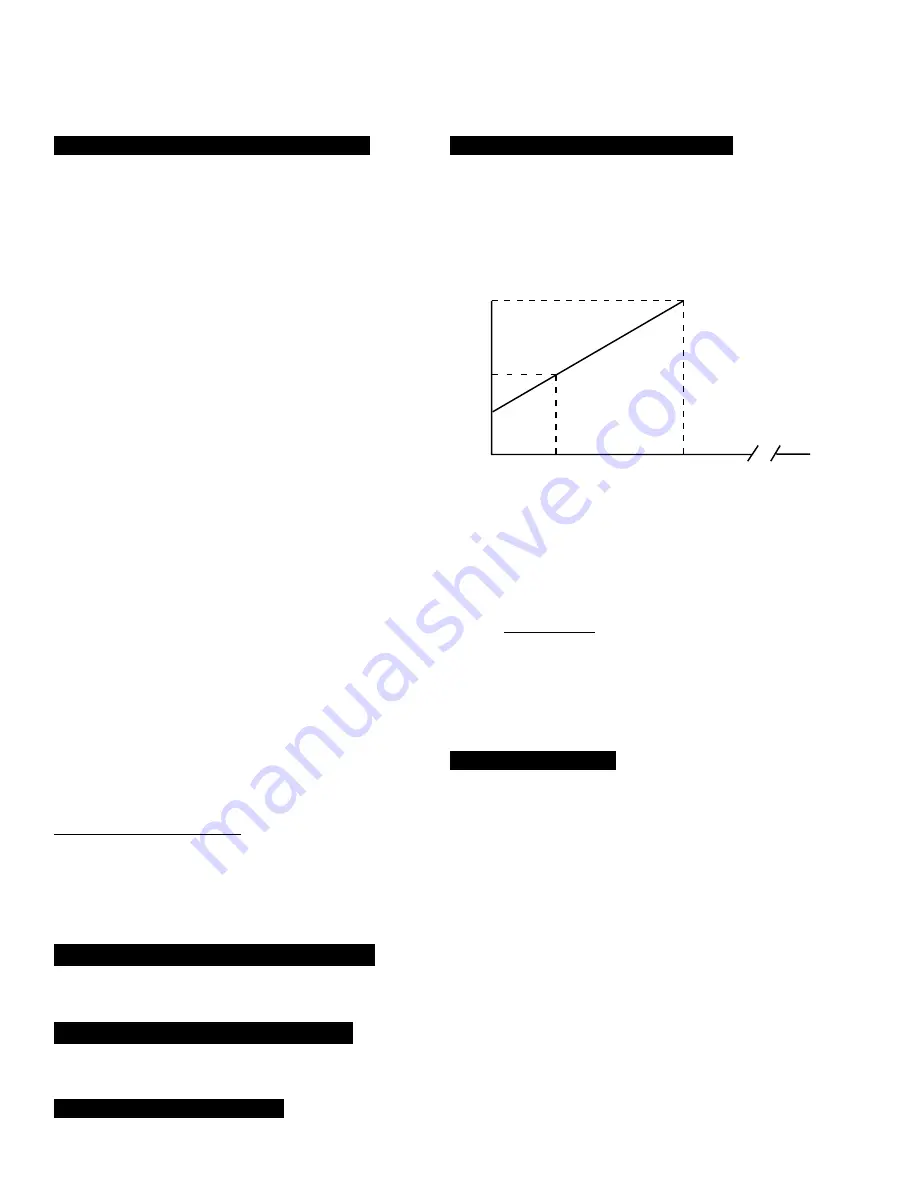

PULL DOWN DEMAND – This function is used to pro-

vide energy savings by limiting fuel or steam consump-

tion during the first 1 to 255 minutes (programmable) of

unit operation following a unit start. Instead of allowing

the load command to rapidly increase to 100%, due to

the typical high load conditions at start, the hot water

valve (hot water unit) or steam valve position (steam

units) is restricted to ramping up from a maximum al-

lowed starting load limit to a maximum allowed Stop load

limit over the pull down interval.

The programmable range is 20 to 100%. The pull down

interval is programmable from 1 to 255 minutes. Each

time the unit starts, a timer begins counting down the

pull down interval. Unit loading/unloading is controlled

by the automatic temperature control algorithm. How-

ever, during the pull down interval, it cannot load to a

value greater than the pull down demand limit will allow.

The limit ramps linearly from the programmed START

limit to the programmed STOP limit over programmed

INTERVAL (SETP). The START limit is effective when

the unit starts. The STOP limit is effective when the IN-

TERVAL timer has elapsed. The limit at any time in be-

tween these points can be determined by:

While the unit is operating and the pull down interval

has not yet expired, the present load limit and time re-

maining in the interval can be viewed by pressing the

PULL DOWN DEMAND setpoint key.

PRESENT PULL DOWN LIMIT = XX%; XXX MIN LEFT

is displayed. After the interval has elapsed, pressing this

key displays the programmed interval, start load limit

and stop load limit as follows:

SETP = XXX MIN; START = XX%; STOP = XX%

Any time the interval is in effect and the unit is being

prevented from further loading,

SYSTEM RUN – PULL DOWN LIMIT

is displayed. After

timeout, the pull down limit is no longer in effect. The

following illustrates the load limiting characteristics of a

pull down demand programmed as follows:

SETP = 60 MIN: START = 40%: STOP = 100%

Each time the unit is started, the load is linearly limited

from 40 to 100% for the first 60 minutes of unit operation

as follows:

Using the above formula, the load limit at any time dur-

ing the 60-minute interval can be determined. For ex-

ample, the load limit 20 minutes after unit has started

will be:

CLOCK – The Control Center contains an internal clock

that is an inherent part of the Micro Board. It provides

the day of the week, time of day, and calendar date. If

not programmed, the default value is

SUNDAY 12:00 AM 1/1/92

DAILY SCHEDULE – The Control Center can be pro-

grammed to automatically start and stop the chiller as

desired. This schedule will repeat on a seven-day calen-

dar basis. If the Daily Schedule is not programmed, the

default value is 00:00 AM start and stop times for all

days of the week and the holiday. (Note that the system

will not automatically start and stop on a daily basis with

these default values is 00:00 is an “Impossible” time for

the Micro Board. See “Programming System Setpoints”,

page 94). Finally one or more days in the week can be

designated as holidays (see description under HOLI-

DAY setpoint) and the Control Center can be pro-

grammed (using DAILY SCHEDULE setpoint) to auto-

matically start and stop the chiller on those days so des-

ignated. The operator can override the time clock at any

time using the UNIT switch in LOCAL mode.

Note that if only a start time is entered for a particular

Содержание MILLENNIUM YIA-HW-14F3

Страница 116: ...YORK INTERNATIONAL 115 FORM 155 16 O3 NOTES...

Страница 117: ...116 YORK INTERNATIONAL NOTES...