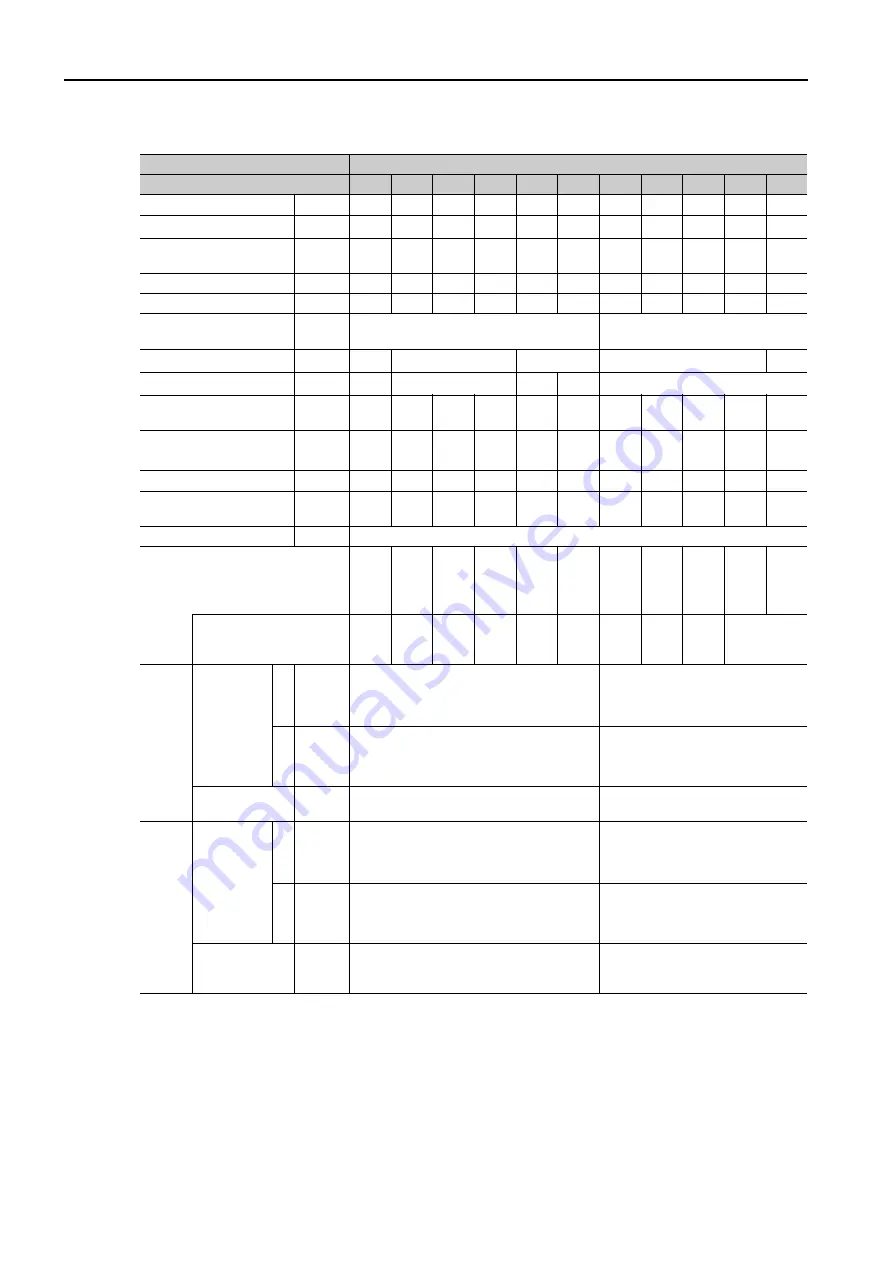

3.2 Specifications and Ratings

3.2.2 Ratings

3-8

SGM7D-

I and -

J

*1.

The rated torques are the continuous allowable torque values at a surrounding air temperature of 40˚C with an

aluminum heat sink of the dimensions given in the table.

*2.

If you use an SGD7S-120A008 SERVOPACK and SGM7D Servomotor together, use the ratios given on the bot-

tom line.

*3.

The thrust loads and moment loads that are applied while a Servomotor is operating are roughly classified into

the following patterns. Design the machine so that the thrust loads or moment loads will not exceed the values

given in the table.

The allowable load is for a static load in one direction.

When designing the system, multiply the allowable load by the following safety coefficient depending on the

type of load.

•

Smooth load with no shock: 1/3

•

Light repetitive load: 1/5

•

Shock load: 1/10

Voltage

200 V

SGM7D-

28I

70I

1ZI

1CI

2BI

2DI

06J

09J

18J

20J

38J

Rated Output

W

264

440

628

817

691

754

75

113

226

251

358

Rated Torque

*1

N

m

28.0

70.0

100

130

220

240

6.00

9.00

18.0

20.0

38.0

Instantaneous

Maximum Torque

N

m

50.0

100

150

200

300

400

8.00

15.0

30.0

45.0

60.0

Stall Torque

N

m

28.0

70.0

100

130

220

240

6.00

9.00

18.0

20.0

38.0

Rated Current

Arms

5.2

5.6

5.5

5.0

5.6

4.8

4.0

3.4

3.0

2.2

3.1

Instantaneous

Maximum Current

Arms

14.1

10.6

Rated Motor Speed

min

-1

90

60

30

120

90

Maximum Motor Speed min

-1

108

72

60

48

144

Torque Constant

N

m/

Arms

6.90

13.9

20.8

27.8

41.5

54.4

1.71

3.29

6.62

9.88

13.3

Motor Moment of

Inertia

×

10

-4

kg

m

2

1800 2000 2300 2850 3400 4000

150

210

240

260

330

Rated Power Rate

kW/s

4.36

24.5

43.5

59.3

142

144

2.40

3.86

13.5

15.4

43.8

Rated Angular

Acceleration Rate

rad/s

2

156

350

435

456

647

600

400

429

750

769

1150

Heat Sink Size

mm

550

×

550

×

30

Allowable Load Moment of Iner-

tia (Motor Moment of Inertia

Ratio)

50

times

125

times

*2

100

times

250

times

*2

90

times

230

times

*2

80

times

200

times

*2

100

times

150

times

350

times

700

times

*2

250

times

600

times

*2

240

times

550

times

*2

220

times

550

times

*2

180

times

450

times

*2

With External Regenera-

tive Resistor and

Dynamic Brake Resistor

800

times

2,000

times

2,500

times

3,000

times

100

times

150

times

700

times

900

times

2,500

times

2,000 times

Allow-

able

Loads

*3

Allowable

Thrust

Load

For

w

ar

d

N

4

×

10

4

3

×

10

4

Reverse

N

2

×

10

4

1

×

10

4

Allowable

Moment Load

N

m

400

200

Rigidi-

ties

Thrust Dis-

placement

Rigidity

Fo

rwar

d

mm/N

2

×

10

-6

3

×

10

-6

Reverse

mm/N

3

×

10

-6

4

×

10

-6

Moment Dis-

placement

Rigidity

rad/N

m

4

×

10

-7

2

×

10

-6