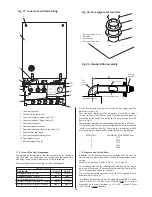

Prepare the flue assembly as described in Section 11.8.

Fit the rubber sealing gasket centrally onto the terminal

assembly and tighten the clamp. Refer to Fig. 28.

Apply the plastic tape to the air duct to be in contact with the

external brickwork.

From inside push the assembly through the wall so that the

gasket flange is against the outer face. Refer to Fig. 28.

It may be necessary to adjust the legs of the flue centering ring.

Align the flue turret and push fully onto the socket on the

appliance. Tighten the clamping ring. Refer to Fig 27.

Seal the gap around the duct at the inner wall face with the

flexible seal provided and make good.

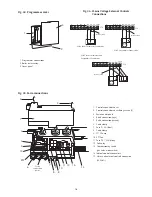

11.12 Flue Bends.

90° and 45° bends are available. A maximum of two bends may

be used in addition to the first bend on the flue turret.

A 90° bend is equivalent to 750mm of straight duct.

A 45° bend is equivalent to 375mm of straight duct.

A maximum flue assembly of 3250mm for natural gas and

1750mm for LPG is possible with 1 X 90° bend and 2500mm

natural gas and 1000mm for LPG with 2 X 90° bends.

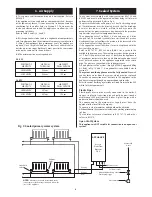

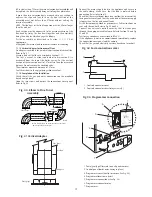

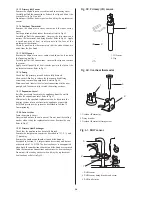

Measure the lengths X,Y and Z. Refer to Fig.29.

The maximum value of X using the turret assembly only is 506mm.

Reduce the ducts to the appropriate length eg. X = 406mm, cut

100mm from the air duct and 120mm (to cover the entry into the

45° or 90° elbow) from the flue duct. Refer to Fig.30.

NOTE:

The flue system ducts between the elbows, dimension Y,

requires the socketed ends (of the first extension if two or more

are used) to be removed and the air and flue tubes to be cut to

the same length.

Cut the ducts to a length Y – 162mm. Refer to Fig.29.

The final section, dimension Z, of the flue system must include a

section of plain duct assembly eg. an extension assembly with

the sockets removed. Reduce the final section, including the

terminal assembly, by the appropriate amount eg:

Air duct Z - 81mm and the flue duct Z – 51mm. Refer to Fig.29.

If Z is less than 425mm it will be necessary to cut the air and flue

ducts of the extension to a plain length of 100mm and reduce

the length of the terminal assembly eg. Z=350mm - remove

75mm from the terminal assembly.

If Z is between 425 - 725mm it is not necessary to cut the

terminal assembly or use a second extension duct as the length

can be set telescopically.

16

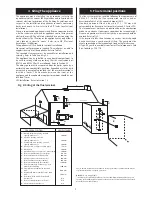

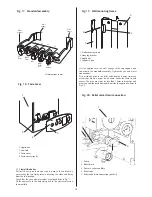

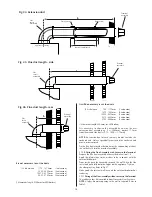

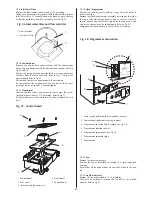

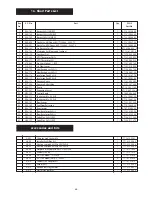

Fig. 27 . Flue Turret Fixing

1

2

3

1. Flue turret assembly

2. Clamp

3. Appliance

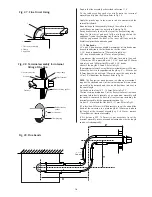

Fig. 28 . Terminal assembly for internal

fitting of the flue.

Flue centering ring

Flue Terminal

Rubber sealing

gasket

Clamping ring

Flue terminal

Air duct

Flue duct

Rubber sealing gasket

Fixing clamp

Fig. 29. Flue bends

X

Z

Y

Y-162

Plain tube