9

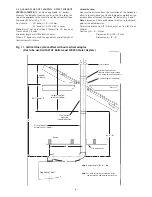

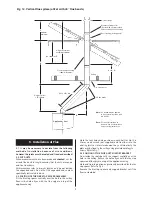

Air inlet flange

Weather sealing collar

(Secure with screw provided

and seal with silicone sealant)

Roof flashing (not supplied)

Flat roof

Pitched roof

Ceiling

Fire stop spacer

Note:

45° bends may be applied

in any system layout as with

90° bends.

Note:

For more information on

bends in flue see installation

and servicing instructions.

45° flue bends

Appliance front

300mm

minimum

Flue terminal assembly

(106mm diameter)

F

G

= 1100mm -

F

Height of offset

=

D

+ 60mm

(1.414 x

D

) - 60

K

Height of terminal

assembly 1100mm

L

=

K

-

G

D

Fig. 12. Vertical flue system (offset with 45° flue bends)

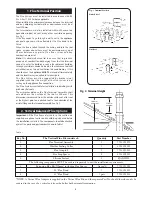

5.1 It may be necessary to deviate from the following

method of installation because of site conditions,

however, the joints must be sealed and fixed as described.

5.2 CUT DUCTS

When measurements have been made and

checked

, cut the

air and flue ducts to length ensuring that the cuts are square

and free from burrs.

All dimensions refer to straight lengths and do not include

the expanded ends. Do not cut the expanded ends unless

specifically instructed to do so.

5.3 POSITION OF THE FIRE STOP SPACER ASSEMBLY

Fit the fire stop spacer centrally over the hole in the ceiling.

Ensure the hole aligns with the flue spigot on top of the

appliance casing.

5. Installation of Flue

Mark the four fixing hole positions in each half for No.10 x

30mm wood screws (not supplied) and fix either into the

existing joists or into reinforcement nogs. Alternatively, the

plate may be fixed to the ceiling using plasterboard toggle

screws. Refer to Fig. 7.

5.4 POSITION OF THE FLUE DUCT SUPPORT BRACKET

From inside the roof space fit the support centrally over the

hole in the ceiling. Ensure the hole aligns with the fire stop

spacer and flue spigot on top of the appliance casing.

Mark and fix into position as previously described for the fire

stop spacer. Refer to Fig. 6.

Remove the fire stop spacer and support bracket until the

flue is assembled.