Motor brake

Maintenance

specifications

EGdoc021716

6-2

6

6.2

Maintenance

IMPORTANT!

Brakes with defective armature plates, cheese head

screws, springs or flanges must be replaced completely.

Please observe the following for inspections and maintenance operations:

Remove impurities through oil and grease using brake cleaning agents, if necessary, replace brake

after finding out the cause of the contamination. Dirt deposits in the air gap between stator and

armature plate impair the function of the brake and must be removed.

After replacing the rotor, the original braking torque will not be reached until the run

−

in operation of

the friction surfaces has been completed. After replacing the rotor, run

−

in armature plates and

flanges have an increased initial rate of wear.

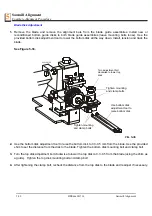

Checking the rotor thickness

DANGER!

The motor must not be running when checking the rotor

thickness.

Remove the motor cover and seal ring (if mounted).

Measure the rotor thickness with a caliper gauge. On brakes with friction plates, observe edging on

outer diameter of friction plate.

Compare measured rotor thickness with minimally permissible rotor thickness

Replace the complete rotor if necessary.

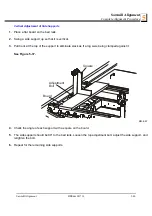

Check air gap

Measure the air gap "s

Lü

" between armature plate and rotor using a feeler gauge (see chapter 3.3).

Compare the measured air gap to the maximum permissible air gap "s

Lümax.

" (see table below).

If necessary, adjust air gap to "s

Lürated

".

Brake Type

sLürated

+0.1mm

-0.05mm

sLümax

Service

Brake

Max.

adjustment

permissible wear

Rotor thickness

Excess of the

adjuster nut

h

Emax.

[mm]

min.

1)

[mm]

max.

[mm]

INTORQ BFK458-25

0,4 mm

(1/64”)

1,0 mm

(3/64”)

4,0 mm (5/32”)

12 mm

(15/32”)

16 mm

(5/8”)

17 mm

(43/64”)

TABLE 12-2

!

Содержание LT70M AH Super

Страница 1: ...Table of Contents Section Page Table of Contents SW 07doc0217161...

Страница 2: ......