Sawmill Alignment

Complete Alignment Procedure

5

5-37

HDSdoc021716

Sawmill Alignment

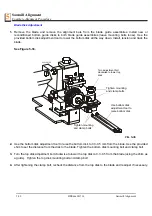

Blade Guide Flange Spacing

Each blade guide must be adjusted so the roller flange is the correct distance from the back edge of the

blade. If the flange is too close to or too far from the blade, the sawmill will not cut accurately.

HINT:

When adjusting blade guide spacing, loosen the top set screw and one

side set screw only. This will ensure horizontal and vertical tilt adjustments are

maintained when the adjustment screws are retightened.

1.

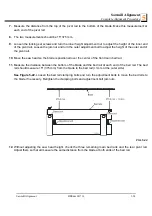

Measure the distance between the flange on the inner blade guide roller to the back edge of the blade. This

distance should measure 1/16" (1.5 mm). Adjust the roller back or forward if necessary.

See Figure 5-34.

Loosen the top and one side screw shown and rear adjusting bolt if necessary. Tap the

blade guide forward or backward until properly positioned. Retighten the screws and jam nuts.

2.

Measure the distance between the flange on the outer blade guide roller to the back edge of the blade. This

distance should measure 1/8" (3.0 mm). Adjust the roller back or forward if necessary.

3.

Check the blade guide disks and drive side deflector plate are properly adjusted. (

).

Blade Guide Level

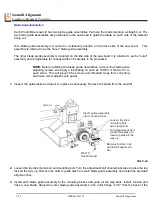

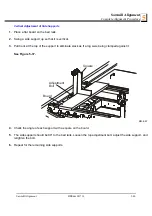

Perform the following adjustments to make sure the blade guide assembly is parallel to the blade.

1.

Loosen the alignment bar mounting bolt. Use the provided bottom disk adjustment tool to adjust the

alignment bar up so the bar is close to, but not touching the bottom of the blade. Retighten the alignment bar

FIG. 5-34

1/16”[1.5mm] (Inner Blade

Guide)

1/8”[3.0mm] (Outer Blade

Guide)

Loosen top and one side

adjustment screw

Loosen rear bolt if

necessary

Содержание LT70M AH Super

Страница 1: ...Table of Contents Section Page Table of Contents SW 07doc0217161...

Страница 2: ......