https://www.XPOtool.com

Item 63003

Page 24

The Tool Experts

01 2022

-1

Suction tube loose

Tighten the suction tube.

D)

PRIME/SPRAY

valve is on

SPRAY

and there is flow

through return tube.

PRIME/SPRAY

valve dirty or worn

Take sprayer to qualified workshop.

E) Spray gun leaks.

Internal parts of the gun worn or

dirty

Take sprayer to qualified workshop.

F) Tip guard assem-

bly leaks.

Tip incorrectly assembled

Check tip assembly and assemble

properly.

Washer worn

Replace the washer.*

G) Spray gun does

not spray.

Spray tip or gun filter clogged.

Clean spray tip or gun filter.

Spray tip not fully on

SPRAY

posi-

tion.

Turn tip to

SPRAY

position.

H) Paint pattern is tail-

ing.

Set pressure too low

Increase pressure.

Gun or suction filter clogged

Clean filters.

Suction tube loose at inlet valve

Tighten suction tube fitting.

Tip worn

Replace spray tip.

Paint too thick

Thin the paint.

Pressure loss

Refer to causes and solutions for prob-

lem C.

* Special repair kits with instructions are available for these procedures.

** Additional parts are available for this procedure.

Daily maintenance

The only daily maintenance necessary is thorough cleaning and lubricating after usage. Follow the

cleaning and lubricating procedures in this manual.

Extended maintenance

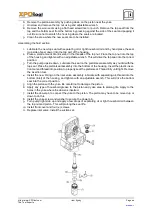

Some pump parts eventually wear out from use and must be replaced. The following list indicates the

available repair kits for the parts replaced by each kit. However, pump performance is the only reliable

indicator of when to replace wear parts. Refer to the “Troubleshooting” section for more information on

when to use these kits.