Pump and Fluid Systems

Chapter 5: Assembly/Disassembly

weatherford.com

28

MP-16 2-Piece 5000 psi January 2013

4.2.1

Initial Operations Maintenance

Magnets in the Lube Oil Strainer/Filter

During the first 500 hours or so of new pump operation, special attention should be given

to the magnets in strainer cage. After every 50 hours of operation, the strainer should be

removed and the lubrication oil magnets inspected. Look for any particulate matter on the

magnets, and clean them each time in accordance with standard procedures.

Repeat this process until such a time as the magnets cease accumulating particulate

matter. At that point, simply apply normal regular maintenance procedures.

Pinion and Main Gear

Some corrective pitting of the main gear is expected during the initial operation period.

These pits should be small, round or oval in shape and dispersed along the pitch line of the

gear teeth. If they expand significantly, form single larger pits or do not slow down and halt

during or after the initial operations period, the entire gear train should be thoroughly

inspected and the cause of the problem rectified. Replace any components that are worn

beyond the recommended clearance.

4.2.2

Fastener Torque Specifications

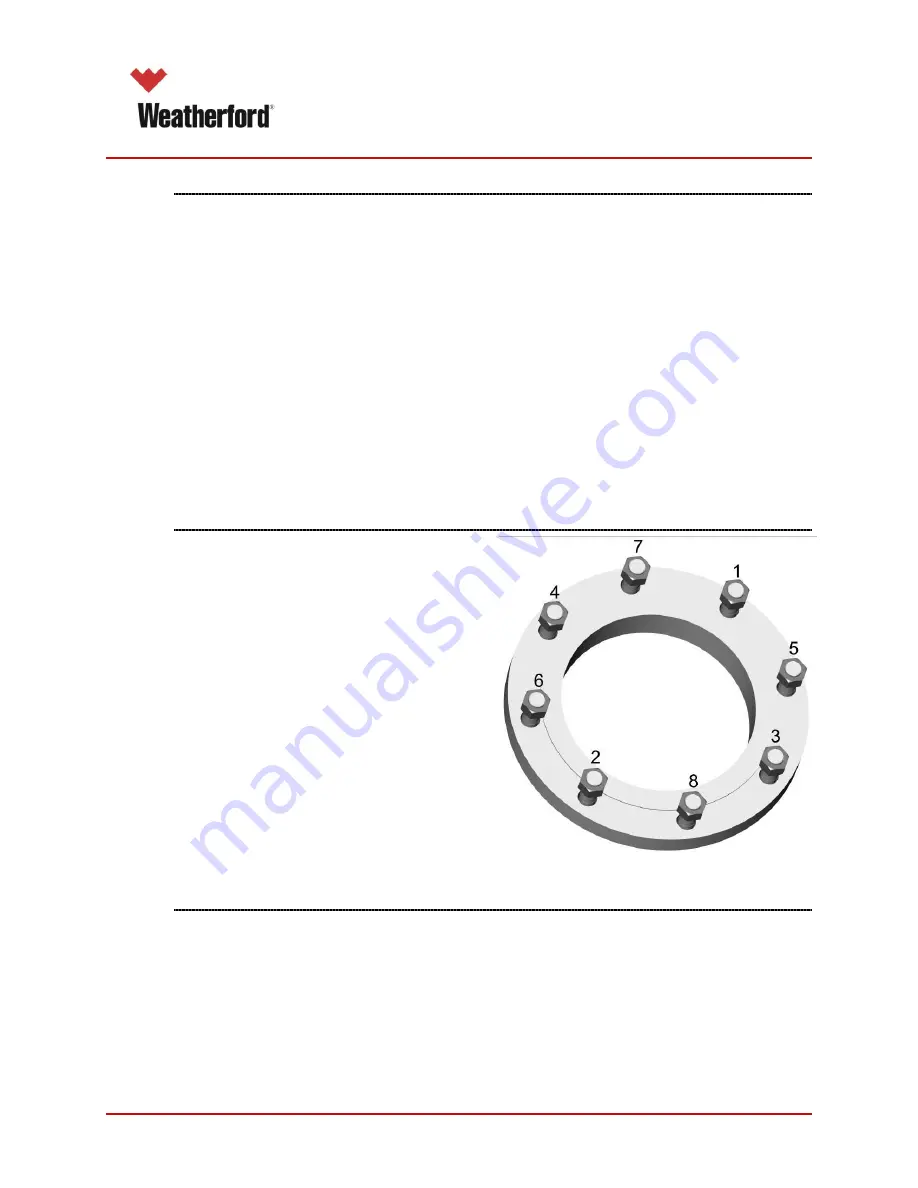

When tightening multiple bolts on flanges, it

is considered the best practice to tighten

opposite bolts first, to ensure a tight flat seal.

The diagram below provides a recommended

order in which to tighten the bolts to best ensure

a tight seal.

In addition, it is generally best to first tighten

each bolt as far as possible by hand without

inflicting pain or injury. Once all bolts are so

tightened, tighten each bolt to one-half torque

tightness, and then finish by tightening each to

full torque tightness once all bolts are at the half-

torque level of tightness.

For exact torque values for specific bolts,

consult the Torque Chart on page 49.

4.2.3

Biannual Inspection

It is recommended that, in addition to the procedures and processes outlined below, the

MP-16 triplex pump should receive a complete inspection about once every two years. This

inspection should cover all components and systems, checking for wear and tear and

ensuring that the pump is still in good operating condition. All damaged, defective or

otherwise nonfunctional components should be repaired if possible or replaced.