Pump and Fluid Systems

Chapter 3: Operations

weatherford.com

25

MP-16 2-Piece 5000 psi January 2013

3.3.4

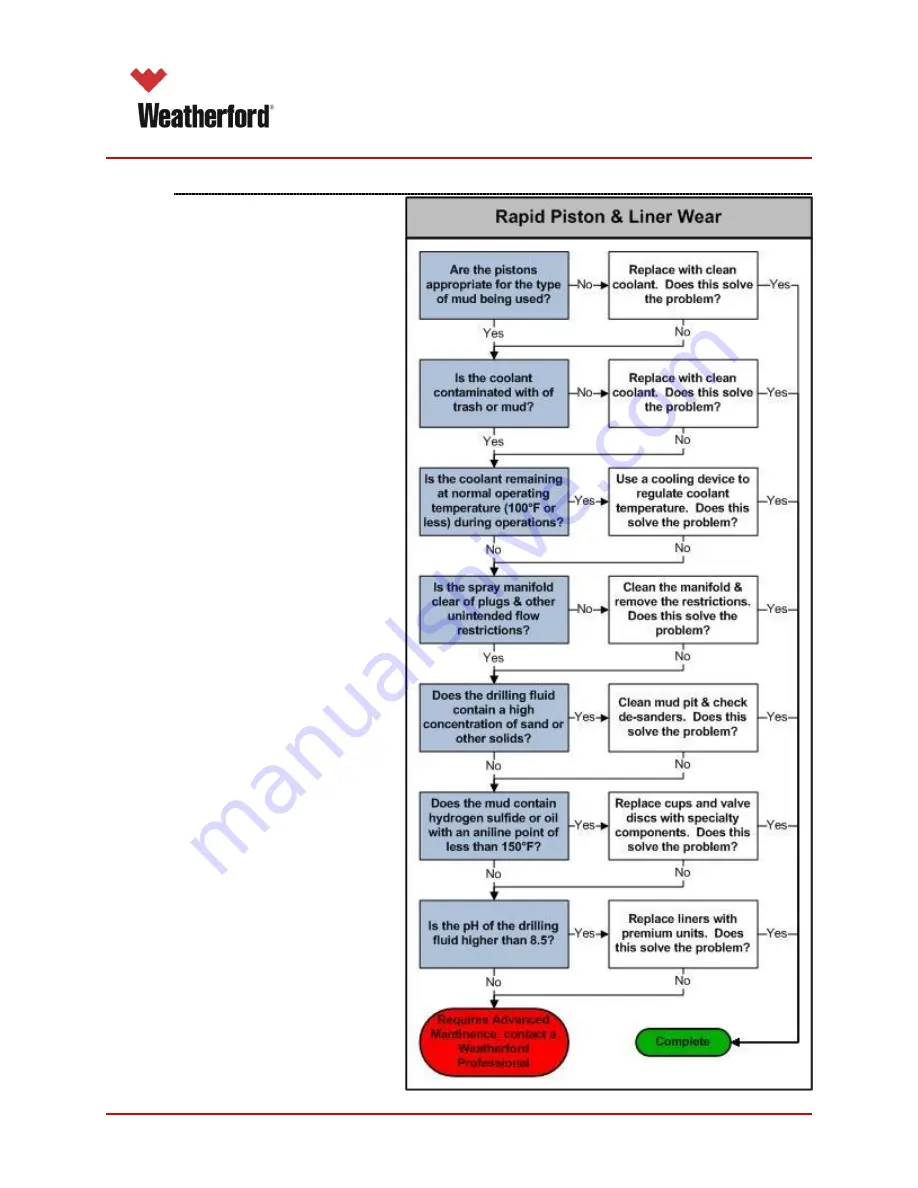

Rapid Piston & Liner Wear

In most cases, faster than

normal wear of the pistons and/or

liners is the result of either problems

with the coolant or the mud. First,

make sure the pistons being used

are appropriate for the type of mud

being run. Then check that the

coolant is at a normal operating

temperature (100°F or less), and is

not contaminated with trash or mud.

Then double check the spray

manifold nozzles and holes drilled in

the coolant rods to ensure that they

are spraying sufficient coolant into

the liner. Remove any plugs or

restrictions on the coolant flow.

Drilling fluid that contains a high

concentration of sand or other

solids will rapidly degrade pump

components, usually evidenced by

streaks in the liner bores. In such

cases, the mud tanks should be

cleaned, and the de-sanders should

be checked and replaced as

needed.

If the drilling fluid has a pH

above 8.5, then it is considered

corrosive, and will cause excessive

damage to normal liners. If the mud

contains hydrogen sulfide, or if oil-

based and the aniline point of the oil

is less than 150°F, then it will attack

and rapidly deteriorate the piston

cups and valve discs. In all such

cases,

premium

or

specialty

components should be used to

reduce deterioration.

If none of these solutions help,

contact a Weatherford professional.