Pump and Fluid Systems

Chapter 3: Operations

weatherford.com

24

MP-16 2-Piece 5000 psi January 2013

3.3.3

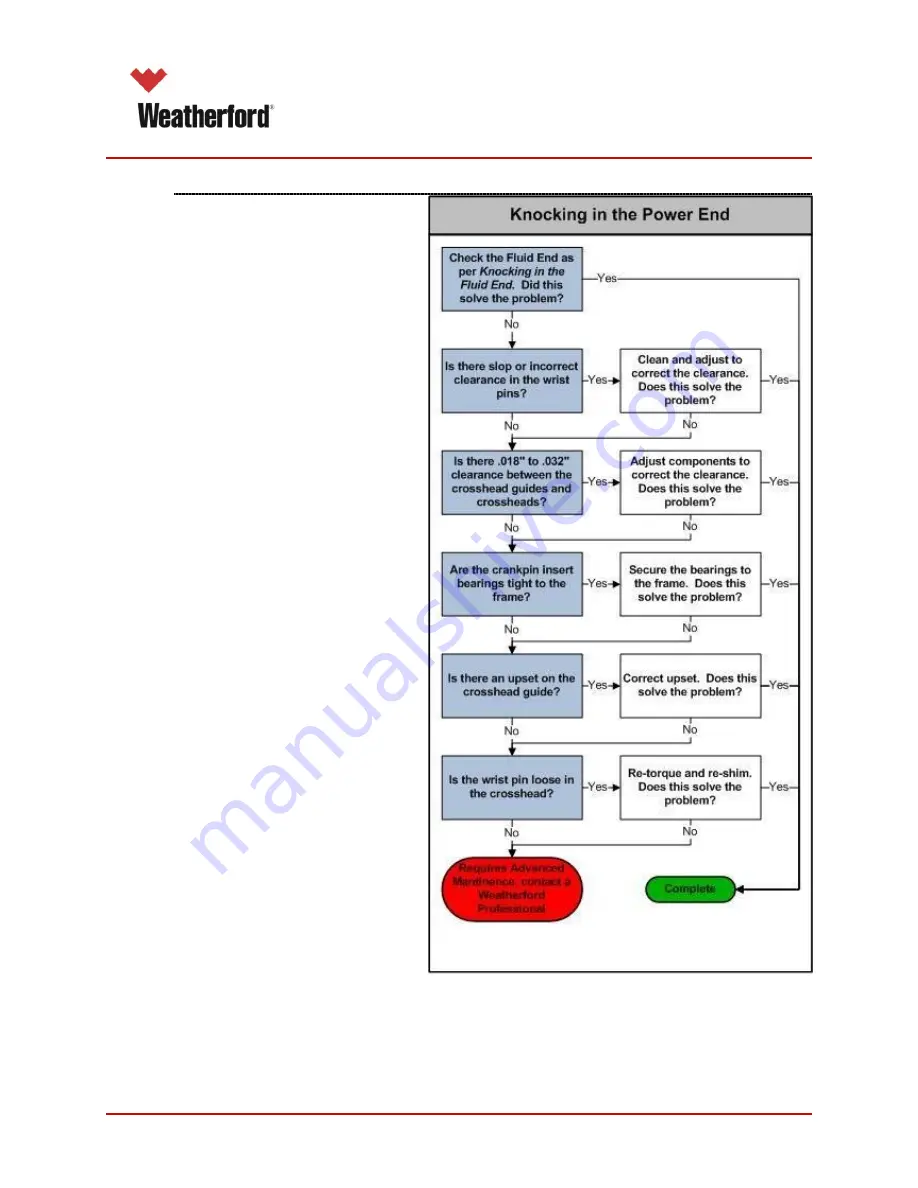

Knocking in the Power End

Even in cases where the knocking

appears to be coming from the power

end of the pump, it is much more likely

that they are caused by conditions in

the drilling fluid than by the actions of

the power end equipment. Therefore,

before checking the power end for

potential causes, you should consult

3.3.2: Knocking in the Fluid end and

follow the procedure outlined there.

If the problem is not in the fluid end,

then check for slop in the wrist pins.

The wrist pins should have a clearance

of no more than 0.002” between the

wrist pin and the crosshead. Insert a

0.002” feeler gauge and see if it will fit

through all 360.

Next, check the clearance of the

crossheads,

which

should

have

between 0.014

” and 0.030” between

them and the guides. Also check the

crankpin insert bearings, which should

be tight in the frame, and can cause

knocking when loose. Finally, check

the crosshead guides for upsets, as

these can also cause knocking.

If none of the above is the case,

you will need to disassemble the power

end so you can access the wrist pin

(see 5.2: Power End Maintenance

Procedures). Remove the outer

screws in the retaining plate and bump

the pin lightly. If it moves easily in the

crosshead, then the pin and bearing

should be removed and reinstalled or

replaced if damaged (as per 5.3.5:

Installing the Wrist Pin Bearing).

If none of these solutions help,

contact a Weatherford professional.