14

Part No. 920559 Rev H

November 2008

2.9 iMeter or Xflo™ Meter Calibration Procedure

Sufficient product must be run through each meter to thoroughly flush out all air and completely fill the system

prior to the calibration process.

Each meter assembly contains two meters. The WIP pulser (or XWIP for Xflo meter) contains two sets of sen-

sors, one set for each meter. On the front of the pulser, there are two calibration doors, one for each meter in

the assembly. The door closest to the front of the dispenser controls calibration of the front meter and the other

door controls calibration of the rear meter.

Only one door may be opened at one time during meter calibration

(only one meter at a time can be calibrated).

It is important to verify the product grade for each assembly to

assure the correct door is opened during the calibration process.

Dispensers have an operation mode setting that establishes the pulser’s calibration mode. This is set at the fac-

tory in the dispenser template (Read Only function F16). The imeter and the Xflow meter are calibrated using

the same procedure as shown below.

Verification Accuracy:

1. Dispense some product into the test measure to wet the container and then drain the container thor-

oughly, 10 seconds or more.

2. Dispense product into test measure until exactly 5 gallons (20 liters) are shown on dispenser display.

See Note 1.

3. Compare reading on site glass of test measure to dispenser display. Volume in test measure should be

/- 3 cu. in. (+/- 50 ml). See Note 2.

4. If values are out of range, calibrate as described below.

Calibration:

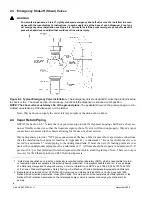

1. Identify calibration door for meter in need of calibration.

2. Remove seal wire and pin to allow access to door.

3. Dispense some product into the test measure to wet the container and then drain the container thor-

oughly, 10 seconds or more.

4. Open calibration door of meter to be calibrated. (Only one door can be opened at a time during the cali-

bration process).

5. Dispense exactly 5 gallons (20 liters) into the test measure exactly to the “0” mark on the sight glass

(read the bottom of the meniscus).

6. Close the calibration door. (This now redefines the calibration factor in the pulser).

7. Empty the test measure (drain completely, 10 seconds or more) and verify accuracy as described above.

8. Seal calibration door.

Note 1:

In the Liter mode, in addition to 20 liters, a 10 liter or 5 liter test measure may be used if required

by the application. However, you should check with your jurisdiction on Weights & Measures tolerance

requirements.

Note 2:

For the U.S. and Canada, acceptance tolerance of ±3 cu.in. for a 5 gallon measurement and ± 50

ml for a 20 liter measurement is only required for newly installed, newly placed in service devices for 30

days. After 30 days, the tolerance is increased to ±6 cu.in. for 5 gallons and ±100 ml for 20 liters.

Содержание Ovation

Страница 1: ...INSTALLATION Ovation Dispensers OPERATION...

Страница 3: ...November 2008 Part No 920559 Rev H Ovation Series Dispensers Installation Operation...

Страница 4: ...November 2008 Part No 920559 Rev H...

Страница 54: ...48 Part No 920559 Rev H November 2008...

Страница 66: ...60 Part No 920559 Rev H November 2008...

Страница 67: ...61 November 2008 Part No 920559 Rev H DISTANCE BETWEEN EYE BOLTS 33 1...

Страница 68: ...62 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R13...

Страница 69: ...63 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R13...

Страница 70: ...64 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL B23...

Страница 71: ...65 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL B23...

Страница 72: ...66 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODELS B12 AND R22...

Страница 73: ...67 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODELS B12 AND R22...

Страница 74: ...68 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R11...

Страница 75: ...69 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R11...

Страница 76: ...70 November 2008 Part No 920559 Rev H...

Страница 77: ...71 November 2008 Part No 920559 Rev H 2 7151 C TYPICAL SITE WIRING...

Страница 78: ...72 Part No 920559 Rev H November 2008...

Страница 80: ...74 Part No 920559 Rev H November 2008...

Страница 81: ...75 November 2008 Part No 920559 Rev H APPENDIX D SITE INTERCONNECTION DIAGRAMS...

Страница 82: ...76 Part No 920559 Rev H November 2008 Figure D 1 Backroom Installation Wayne Control System...

Страница 84: ...78 Part No 920559 Rev H November 2008 Figure D 3 Pump Relay Installation Wiring Diagram...