17

November 2008

Part No. 920559 Rev H

2.10 Balance Vapor Recovery System Installation Requirements,

continued

6. If back pressure readings are very low (less than .02 @ 20 CFH; 0.18 @ 60 CFH; 0.4 @ 100 CFH):

1. Check test fixture for tight seal at nozzle entry point.

2. Check bellows and face seal for tears.

3. Check vapor piping for leaks.

7. If back pressure readings are high:

1. Check hoses and nozzle bellows are completely drained.

2. Check dry break is open. (If only allowed to have one dry break open during the test, try all.)

3. Check vapor pod.

4. Check vapor impact valve to be open.

5. Check piping under dispenser. Should be a minimum of 1 inch diameter piping and fitting.

6. Check dispenser back pressure, disconnected from the underground and compare to dispenser base line

data.

7. Check hanging hardware separate from dispenser and compare to balance hardware matrix base line

data.

8. Check outlets, hose, and underground, for suspect blockage problems due to fitting bottomed out or

casting flashing. Flashing is aluminum edges left over when the casting was made. This should be your

last resort to diagnosing high back pressure readings since piping will have to be removed to look

inside the casting for flashing. A large amount of flashing would be required to affect readings.

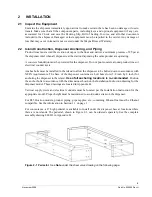

2.10.3 Nozzles Approved for Balance System

The Ovation nozzle boot hook can be adjusted to accommodate different nozzles. Table 2-1 shows the nozzles

approved for use with a balance system and the hook position for each nozzle. Position 1 is the standard posi-

tion. The hook is in position 1 in the accompanying photo. To change positions, remove the (4) screws shown,

slide the hook down to the new position, and reinstall the (4) screws to secure the hook to the boot.

Table 2-1 Nozzle and Nozzle Hook Position

NOZZLE

HOOK POSITION

Emco Wheaton A4005

3

Emco Wheaton A4015

1

OPW 11VF47

4

Husky V Model 5010 and 5020

3

Husky V(short) Model 5110 and 5210

1

1/4-20

Screws (4)

Содержание Ovation

Страница 1: ...INSTALLATION Ovation Dispensers OPERATION...

Страница 3: ...November 2008 Part No 920559 Rev H Ovation Series Dispensers Installation Operation...

Страница 4: ...November 2008 Part No 920559 Rev H...

Страница 54: ...48 Part No 920559 Rev H November 2008...

Страница 66: ...60 Part No 920559 Rev H November 2008...

Страница 67: ...61 November 2008 Part No 920559 Rev H DISTANCE BETWEEN EYE BOLTS 33 1...

Страница 68: ...62 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R13...

Страница 69: ...63 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R13...

Страница 70: ...64 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL B23...

Страница 71: ...65 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL B23...

Страница 72: ...66 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODELS B12 AND R22...

Страница 73: ...67 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODELS B12 AND R22...

Страница 74: ...68 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R11...

Страница 75: ...69 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R11...

Страница 76: ...70 November 2008 Part No 920559 Rev H...

Страница 77: ...71 November 2008 Part No 920559 Rev H 2 7151 C TYPICAL SITE WIRING...

Страница 78: ...72 Part No 920559 Rev H November 2008...

Страница 80: ...74 Part No 920559 Rev H November 2008...

Страница 81: ...75 November 2008 Part No 920559 Rev H APPENDIX D SITE INTERCONNECTION DIAGRAMS...

Страница 82: ...76 Part No 920559 Rev H November 2008 Figure D 1 Backroom Installation Wayne Control System...

Страница 84: ...78 Part No 920559 Rev H November 2008 Figure D 3 Pump Relay Installation Wiring Diagram...