1

November 2008

Part No. 920559 Rev H

1

INTRODUCTION

This revision of the manual includes new installation footprint drawings. These drawings show the location

of the conduits for entering the new smaller junction box. The smaller junction box will be standard on pro-

duction Ovation dispensers in November 2008. This junction box gives the installation personnel more

room to make inlet and conduit connections, and it also allows for bottom entry of conduits coming up out-

side of the containment box.

1.1 Dispensers Covered

Ovation series dispenser models use the iGEM computer and, either the iMeter assembly with the Wayne

Intelligent Pulser (WIP), or the new Xflo

™

meter assembly with the XWIP. Models with the new Xflo

meter assembly have the letter X in the model number after the second / in the number, for example,

B23/4220D1/JKX/L. There is no difference in the installation and startup of these dispensers, with the only

exception being a one inch change in the location of the field conduit on those models that do not have a

junction box. On those models, the primary conduit location is moved from 1.37 to 2.37 inches off the cen-

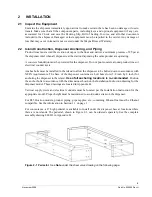

ter line towards the front of the dispenser. Components in a typical Xflo dispenser are shown in Figure 1-1.

E85 Ovation models

have the letter E at the very beginning of the model number and use the Xflo meter

assembly. In addition to the noted change above for Xflo models, internal parts such as the Xflo meter, prod-

uct tubes, and outlet castings, as well as external parts, such as pipes, pipe nipples, hoses, nozzles, break-

aways and swivels that come into contact with the Ethanol fuel must be Ethanol compatible; they must be

either nickel-plated or stainless steel. Pipe nipples at the meter inlets need to be made of stainless steel.

Replacement filters should be 1 micron. The recommended filter for Wayne Ethanol dispensers is Cim-Tek's

Bio-Tek, 1 Micron filter. Standard gasoline dispensers commonly use filters rated at 10 microns.

The iGEM computer runs on software that can be downloaded by a laptop. Dispenser models with the Xflo

meter and XWIP use iGEM rev 46 or later pump software; servTerm version 5.4.2 or later is required for

servicing (loading the computer software or dispenser configuration template), however, this is not required

for installation/startup of the dispenser. If it becomes necessary to reload pump software, always use the lat-

est version. Note: The XWIP case is blue and the iMeter WIP case is black; they are not interchangeable.

Computer function settings that are necessary for Ovation dispenser startup and operation, such as prices,

blending ratios, fueling point number, etc., are included in this manual. If additional information on function

settings and statistics is required, refer to the Ovation Dispenser Service manual, part number 920525-002.

Any questions concerning installation and operation of the dispenser that are not covered in this manual

should be referred to Wayne Technical Support (1-800-926-3737).

Figure 1-1 Location of Components in Lower Section.

MGD, three Xflo Meters, side 2

.

Proportional

Valve and Coil

Check Valves underneath

Cover Plates

Xflo Meter Dome

XWIP

Pulser

Filter

Product Inlet

Содержание Ovation

Страница 1: ...INSTALLATION Ovation Dispensers OPERATION...

Страница 3: ...November 2008 Part No 920559 Rev H Ovation Series Dispensers Installation Operation...

Страница 4: ...November 2008 Part No 920559 Rev H...

Страница 54: ...48 Part No 920559 Rev H November 2008...

Страница 66: ...60 Part No 920559 Rev H November 2008...

Страница 67: ...61 November 2008 Part No 920559 Rev H DISTANCE BETWEEN EYE BOLTS 33 1...

Страница 68: ...62 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R13...

Страница 69: ...63 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R13...

Страница 70: ...64 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL B23...

Страница 71: ...65 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL B23...

Страница 72: ...66 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODELS B12 AND R22...

Страница 73: ...67 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODELS B12 AND R22...

Страница 74: ...68 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R11...

Страница 75: ...69 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R11...

Страница 76: ...70 November 2008 Part No 920559 Rev H...

Страница 77: ...71 November 2008 Part No 920559 Rev H 2 7151 C TYPICAL SITE WIRING...

Страница 78: ...72 Part No 920559 Rev H November 2008...

Страница 80: ...74 Part No 920559 Rev H November 2008...

Страница 81: ...75 November 2008 Part No 920559 Rev H APPENDIX D SITE INTERCONNECTION DIAGRAMS...

Страница 82: ...76 Part No 920559 Rev H November 2008 Figure D 1 Backroom Installation Wayne Control System...

Страница 84: ...78 Part No 920559 Rev H November 2008 Figure D 3 Pump Relay Installation Wiring Diagram...