WAMFLO

®

FN200X

3.0

3.0 TECHNICAL INFORMATION

2

FIL.WAMFLO_FN200.EX.M.A7.0522.EN Issue: A7

05.22

12

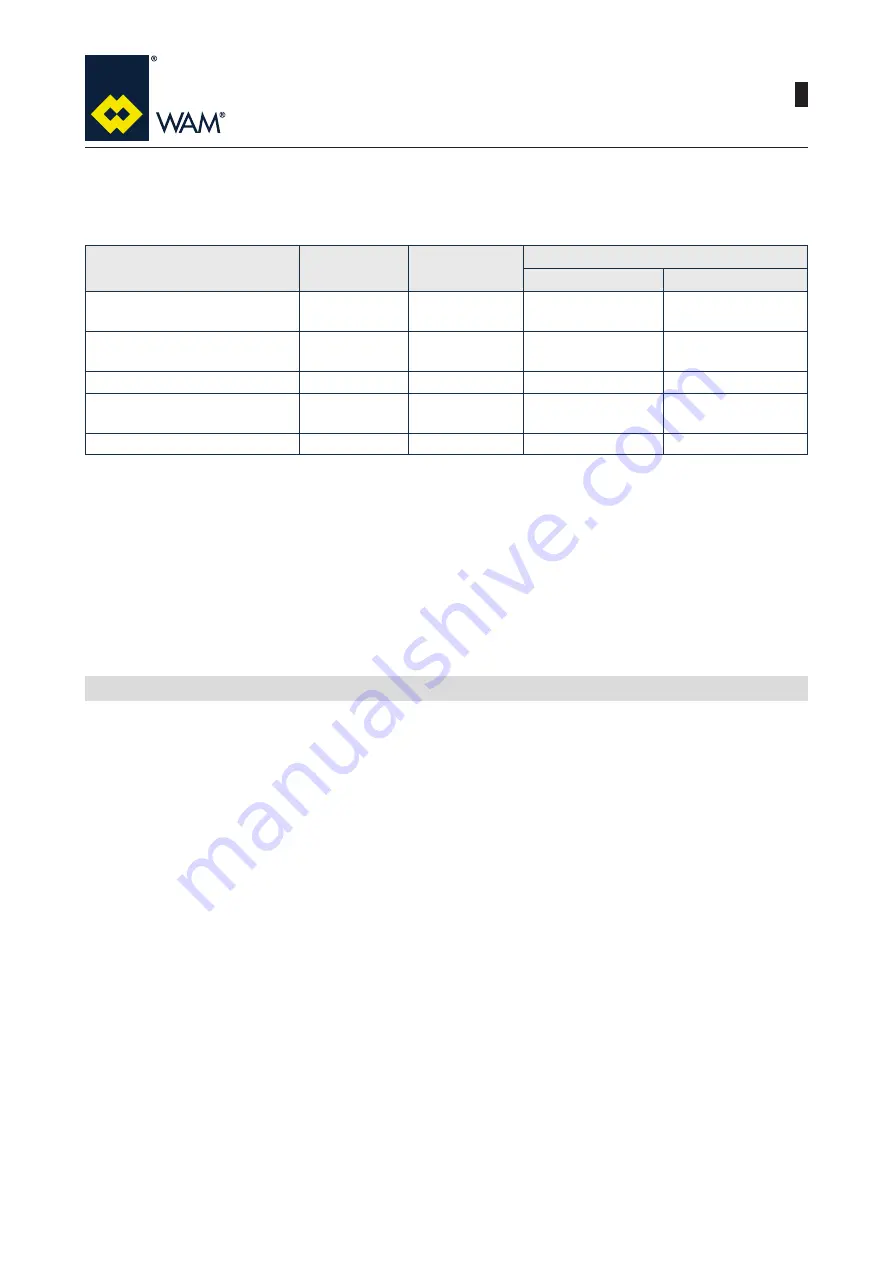

VALUES FOR ST1, ST2 CLASSES

The filter has been designed and tested to work with dust having explosion class St1, St2.

WAMFLO

®

ATEX

has a structural resistance of Pred = 1 bar (10.000 mm H

2

O, 1000 millibar, 100 KPascal).

Parameter

Unit

of measure

Zone 22

cat. 3D

Zone 21 cat. 2D

No fan

With fan

Minimum ignition temperature of

a 5 mm layer of dust (LIT)

°C

>=210

>=155

>=275

Minimum ignition temperature of

suspended powder (MIT)

°C

>=210

>120

>300

Minimum ignition energy (MIE)

mJ

>3

>3

>3

Maximum explosion pressure

(Pmax)

bar

<=9

<=9

<=9

Reactivity parameter (Kst)

bar m/s

<=300

<=300

<=300

The use of the round dust collectors in the presence of dust having other features than those indicated or in

areas with different classification falls under the direct and exclusive responsibility of the user.

NOTE:

The

WAMFLO

®

ATEX

filter must be installed in a plant provided with the suitable prevention, protection

and compartmentalization systems, according to the ATEX Directive, unless the risk analysis of the

system excludes the presence of ignition sources (of the exogenous type or foreign bodies with high

impact energy).

3.4 Compliance with the ATEX Directive

The dust collectors type

WAMFLO

®

ATEX

have been designed and manufactured in compliance with the

essential requirements for safety and health in case of machinery intended for use potentially explosive at-

mospheres zones (ATEX Directive).

WAMFLO

®

ATEX

series dust collector follow the principles of integrated

explosion safety, and they have been designed to:

1.

Avoid as far as possible that the equipment and the protective systems generate or release explosive mix-

tures.

2. Prevent the ignition of a possibly explosive atmosphere, by taking into account the nature of each source of

ignition (electric or not) of the filter.

3.

Optimizing the control and maintenance conditions, to ensure a perfect effectiveness.

4.

To meet predictable environmental conditions.

5.

Allow the outburst of the flame front in a controlled manner (by installing special venting panels) with a direct

or indirect effect, in case an explosion that could endanger persons and goods occurs despite all measures

taken. This allows limiting in a defined manner the area affected by fire and by the pressure generated by a

possible explosion.

6.

NOTE REGARDING PLANT CONFORMITY