7

Installation and maintenance manual atmoCRAFT

GB

3

Safety instructions and regulations

3.1 Safety

instructions

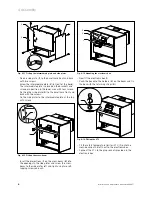

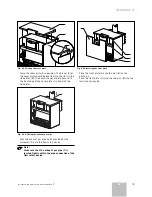

Assembly

The combustion air fed to the unit must be free of

chemicals which contain, e.g. fluorine, chlorine or

sulphur. Sprays, solvents or cleaning agents, paints and

adhesives can contain such materials which can, in

certain circumstances, lead to corrosion when operating

the unit, including the exhaust gas installation.

In business premises such as hairdressing salons,

painting or carpentry workshops, cleaning businesses

etc., also when operating in room-air independent mode,

a separate room must always be used for the installation

which will ensure that the supply of combustion air is

technically free from chemicals.

It is not necessary to keep a clearance between the

appliance and combustible materials or components, as

at the rated heating power of the appliance, the

temperature here is always lower than the permitted

temperature of 85 °C.

Clearances in accordance with Section 4.3 must be

maintained for maintenance purposes.

Note concerning flue design:

The double stage system of the boiler with combustion

air matching produces high values of combustion

technological effectivity. This requires technical evidence

of the suitability of the flue in according with the

relevant standards.

Installation

Before the installation of the boiler, the comments of the

gas supply company and the district chimney sweep

must be obtained.

The boiler may only be installed by a suitably qualified

heating engineer. who also assumes the responsibility

for installing the appliance properly and putting it into

service for the first time.

Flush the heating system thoroughly before connecting the

appliance! By doing that, residue such as welds, cinder,

hemp, putty, rust, rough dust and similar substances are

removed from the pipes. Otherwise such substances can be

deposited in the appliance and cause damage.

Make sure that the connection and gas pipes are not

under stress when installed to avoid leakage in the

heating installation or in the gas connection!

To tighten or loosen bolts, only use suitable open-ended

spanners (do not use pliers or extensions etc.). Improper

use or unsuitable tools can cause damage, such as gas

or water leaks.

On closed heating installations, a type-approved safety

valve corresponding to the heat capacity must be fitted.

The gas regulating block may be tested for leakage only

with a maximum pressure of 50 mbar! Higher testing

pressures can damage the gas fitting.

The electrical installation may only be performed by a

heating engineer.

There is a danger to life by electrocution from current-

carrying components! The supply terminals in the

terminal box of the device are under voltage even if the

mains switch is off. Before working on the appliance,

turn off the power supply and secure against restart.

Important instructions for propane appliances

Bleeding the liquid gas tank when installing the system:

before installing the device, make sure that the gas tank

has been bled. The liquid gas supplier is responsible for

the proper bleeding of the tank. Ignition problems can

be caused if the tank is not bled properly. In such cases,

first contact the person in charge of filling the tank.

Affix tank sticker:

Affix the enclosed tank sticker (propane quality) on the

tank where it is clearly visible, if possible close to the

filler nozzle.

Start-up

Do not add frost or corrosion preventative to the

heating water! If frost or corrosion preventative is added

to the heating water this can cause changes in the seals

and can cause noises to be created during the heating

process. Vaillant assumes no liability for this and such

consequential damages. Please inform the user of the

procedure for frost protection. If the heating water

hardness is above 3,6 mol/m

3

(20 °dH) it should be

softened. To do this you can use the ion-exchanger,

Vaillant spare part number 990 349. Please observe the

enclosed operating instructions.

For natural gas:

If the connected pressure is outside the range 17 to

25 mbar, the unit must not be operated!

For liquid gas: (37 mbar)

If the connected pressure is outside the range 35 to

45 mbar, the unit must not be operated!

Inspection and maintenance

Inspection, maintenance and repair work should only be

undertaken by an approved heating installation company.

Inspections / Maintenance work not carried out can result

in damage to property and personal injury.

Risk of fatal electric shock from touching live

connections! The supply terminals in the terminal box of

the device are under voltage even if the mains switch is

off. Before working on the appliance, turn off the power

supply and secure against restart.

Protect the switch box from water splashes.

Danger of explosion through gas leakage! The mixer tube

between the gas control unit and burner must not be

opened. It can only be guaranteed that this component is

gas-proof after it has been checked at the factory.

Safety instructions and regulations 3

Содержание atmocraft

Страница 1: ...VK 654 9 1654 9 atmoCRAFT DE AT GB...

Страница 2: ......

Страница 44: ...835553_02 DEATGB 092006...