-8-

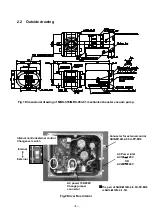

Fig.3 Basic piping diagram

to the vacuum chamber

Show a normal exhaust system drawing in Fig.3.

(1). Connect a fore pump to a downstream side of a

mechanical booster pump.

(2). Install main valve between a mechanical booster

pump and vacuum vessel.

(3). Vent valve2 is a thing to prevent vacuum-pump

oil of an oil-sealed rotary vacuum pump of a fore

pump from flowing upstream to a mechanical

booster pump.

Close main valve, and open vent valve after

having stopped a mechanical booster pump and

a fore pump.

Can omit it in the case of a fore pump

comprising a backflow prevention facility.

When you exhaust an active gas, toxic gas, use a

nitrogen gas for vent.

Note

When open velocity of main valve is early, there are the cases that step out of

magnet coupling comes, and please adjust speed control valve so that in this

case open velocity becomes late.

Caution

Because this pump is complete seal structure. But this pump is for dry air or

the dry nitrogen suck only.

(

MBS-053-01 has surface treatment to MBS-053 and

it is increasing resistance to corrosive gases.

)Please confirm whether a fore

pump supports these gases.

It is feared that explosion of a fore pump, When

you design an evacuation system, confirm a type of an exhaust-gas, and

please execute appropriate plans.

Booster Pump

MBS-053

MBS-053-01